Page 34

a. Motor/Pump Test

The following tests will check the voltage applied to

the motor and the resistance of the motor field

windings.

CAUTION

Line voltage will be measured in this

test. Do not touch uninsulated connec-

tor pins or meter test leads.

b. Step #1

1. Plug the power cord into 120 VAC power

supply (wall receptacle). Turn main switch ON.

2. Disconnect the 3 pin connector CN15 at the

motor. Leave all other connectors connected. See

figure 5-9.

c. Test Results:

If you do not receive the correct meter readings, the

problem could be in the wires, connectors, relay

box, or main switch (refer to appropriate section for

troubleshooting).

If the correct voltage is obtained, everything is good

up to that point and the problem could be either the

motor or the starting capacitor.

d. Step #2

If the starting capacitor is shorted or grounded, the

motor will not run. Capacitors very seldom fail, and

it requires a dielectric tester to accurately test one.

However, an ohmmeter can be used to determine

if the capacitor will store a low voltage charge and

most of the time this is adequate.

1. Turn the main switch OFF.

2. Connector CN15 should be disconnected.

3. Use the R x 100 scale of the ohmmeter and

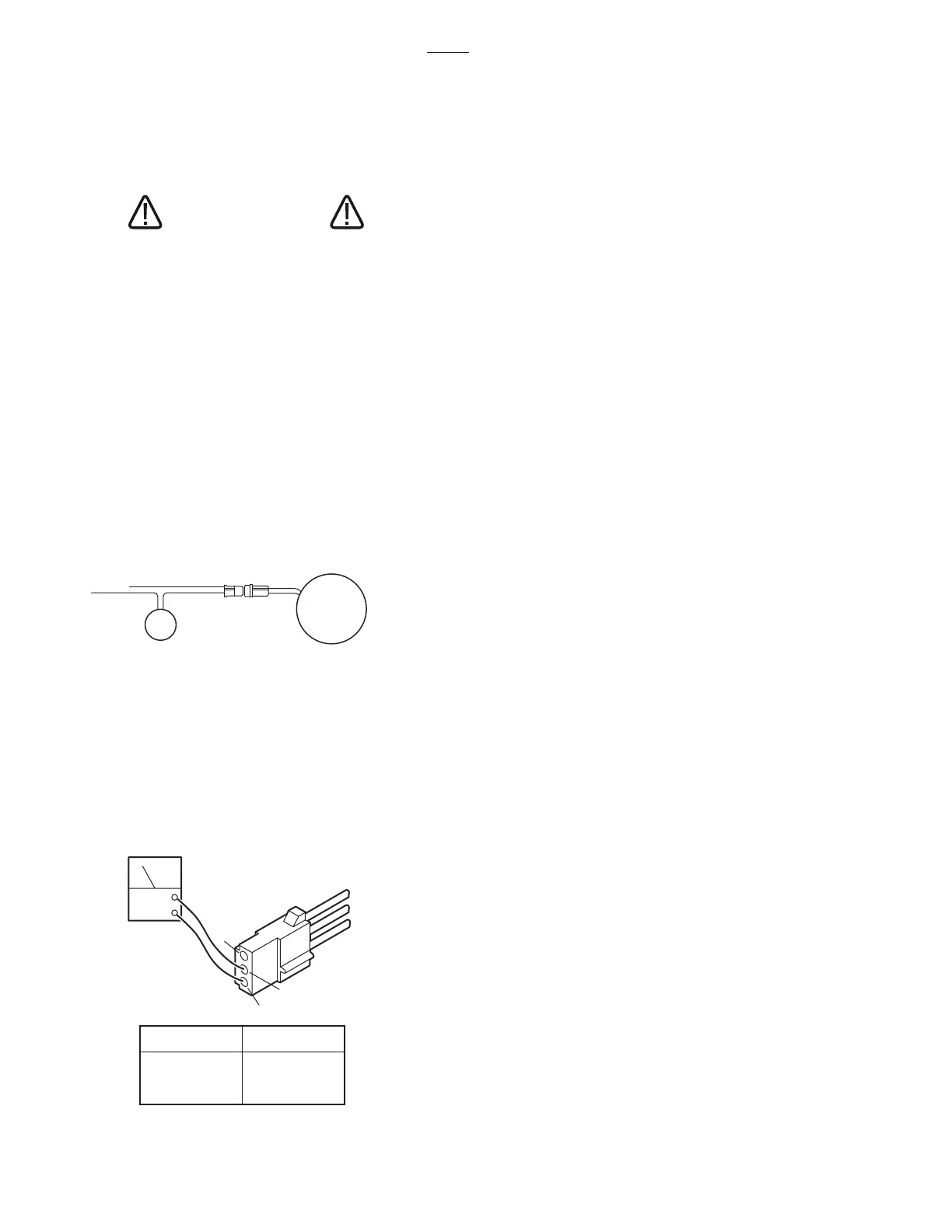

touch pins 2 and 3 of connector CN15. See figure

5-10.

e. Test Results:

The meter needle should move up scale and then

back down to infinity. This would indicate that the

capacitor is storing an electrical charge.

NOTE

The capacitor may have to be dis-

charged first (by shorting pins 2 and 3

together) before you will be able to see

the ohmmeter needle swing up the scale.

f. Step #3

The motor windings can be statically checked for

resistance using an ohmmeter.

1. Turn main power switch OFF.

2. Connector CN15 should be disconnected.

Figure 5-9.

3. Use a voltmeter capable of measuring 120

VAC and measure the following connector pins in

connector CN15. See figure 5-10.

Figure 5-10. Connector CN15

PUMP/MOTOR

ASSEMBLY

CN15

CAPACITOR

ACV

3

2

1

PIN NO

1 - 2

1 - 3

2 - 3

120

120

0

AC VOLTS

3500

Loading...

Loading...