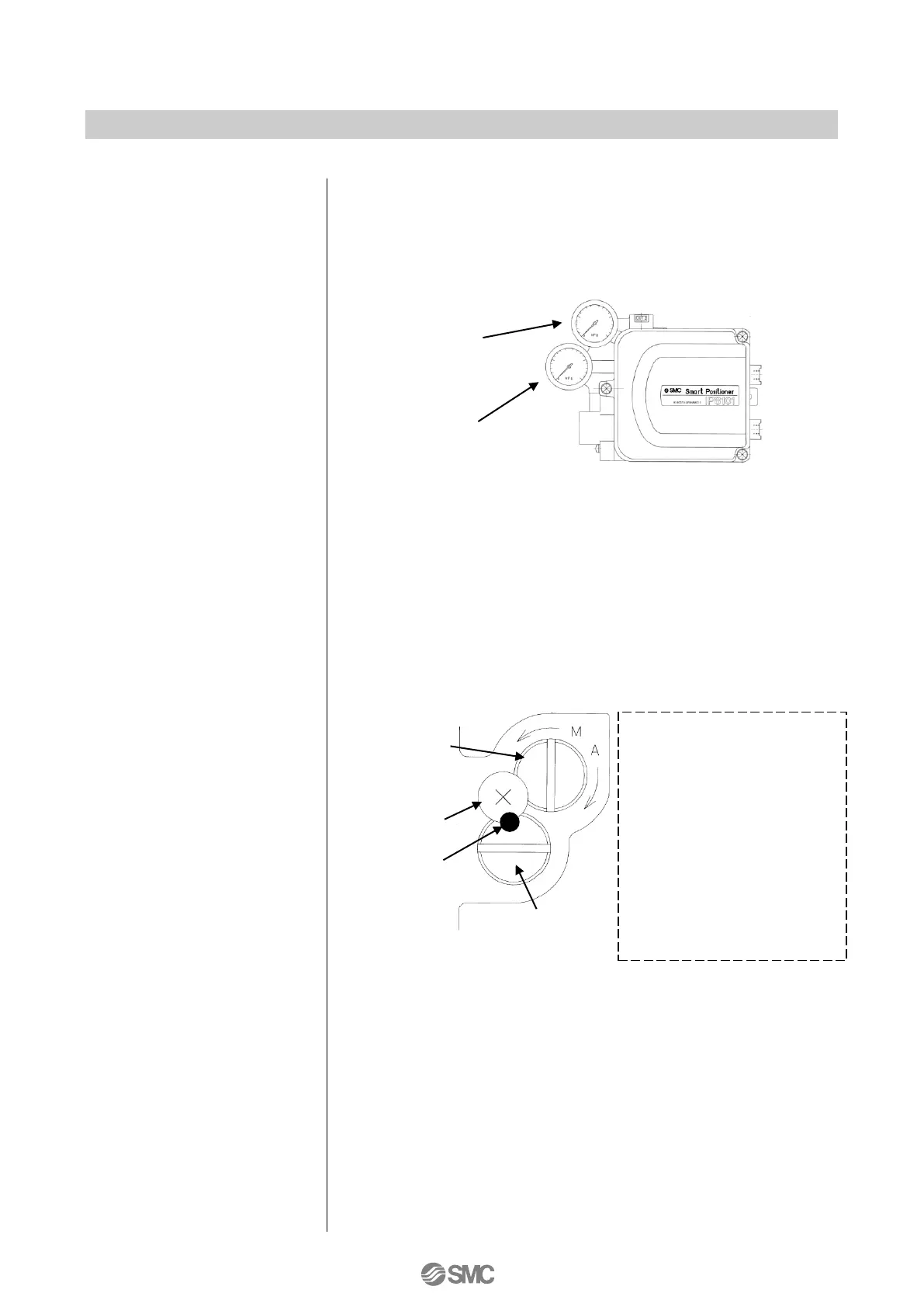

Auto/manual

switch screw

(Built-in fixed orifice)

Stopper screw

(Do not move)

Looseness

prevention

marking

Sensitivity holding screw

(Do not move)

- Be sure to normally tighten

the screw to the auto side

(A) when the positioner is

operated with an input

current.

- Rotation to the manual side

(M) conducts supply

pressure to the OUT1

output. A supply pressure

regulator can adjust the

diaphragm valve and single

acting actuator manual

stroke.

6: Auto and manual mode can be switched by rotating the pilot valve

unit auto/manual switch screw to the manual (M) side as shown in

Fig. 18. A small stopper screw in the top is to prevent loosening and

must not be tampered with or loosened. Also, a sensitivity holding

screw is set prior to factory shipment and must not be accidentally

rotated.

4: The positioner standard stroke is a rotational angle of 60 to 100

o

.

Actuators with a rotating angle of less than 60

o

or over 100

o

are not

available.

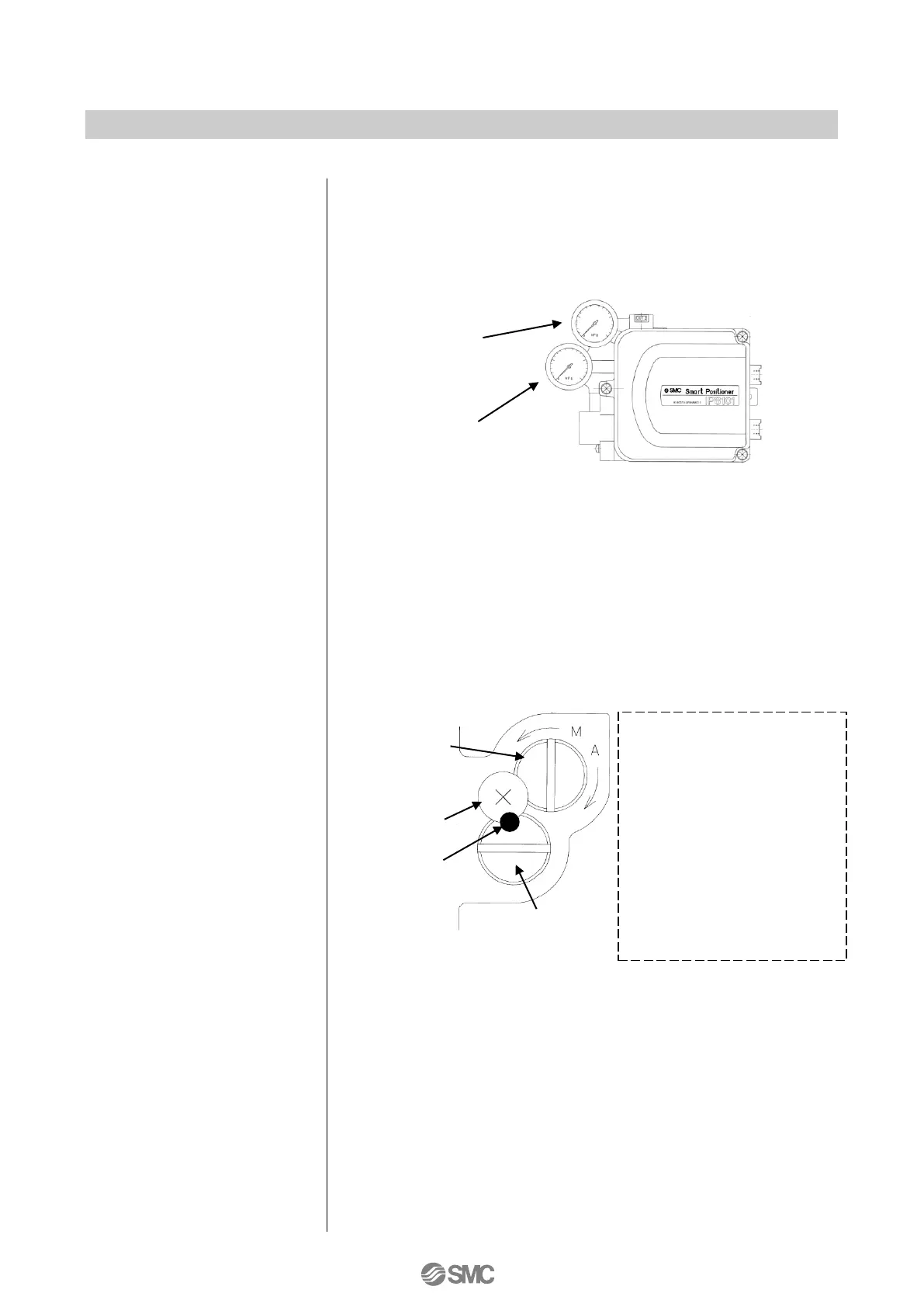

5: A Description of pressure gauges mounted on the positioner are as

shown in Fig. 17.

Loading...

Loading...