2. Adjustment of fork

lever–type fitting angle

Adjust the angle of the fork lever-type fitting connected to the

positioner fork pin unit. Confirm that the actuator operates within

-60 to 60 on the LDC display

*

4

.

Apply the input current and supply

pressure, press Down or Up button

( ) in calibration mode to

select the angle (AnGL), and then

hold down the set button ( )

for 1sec or longer.

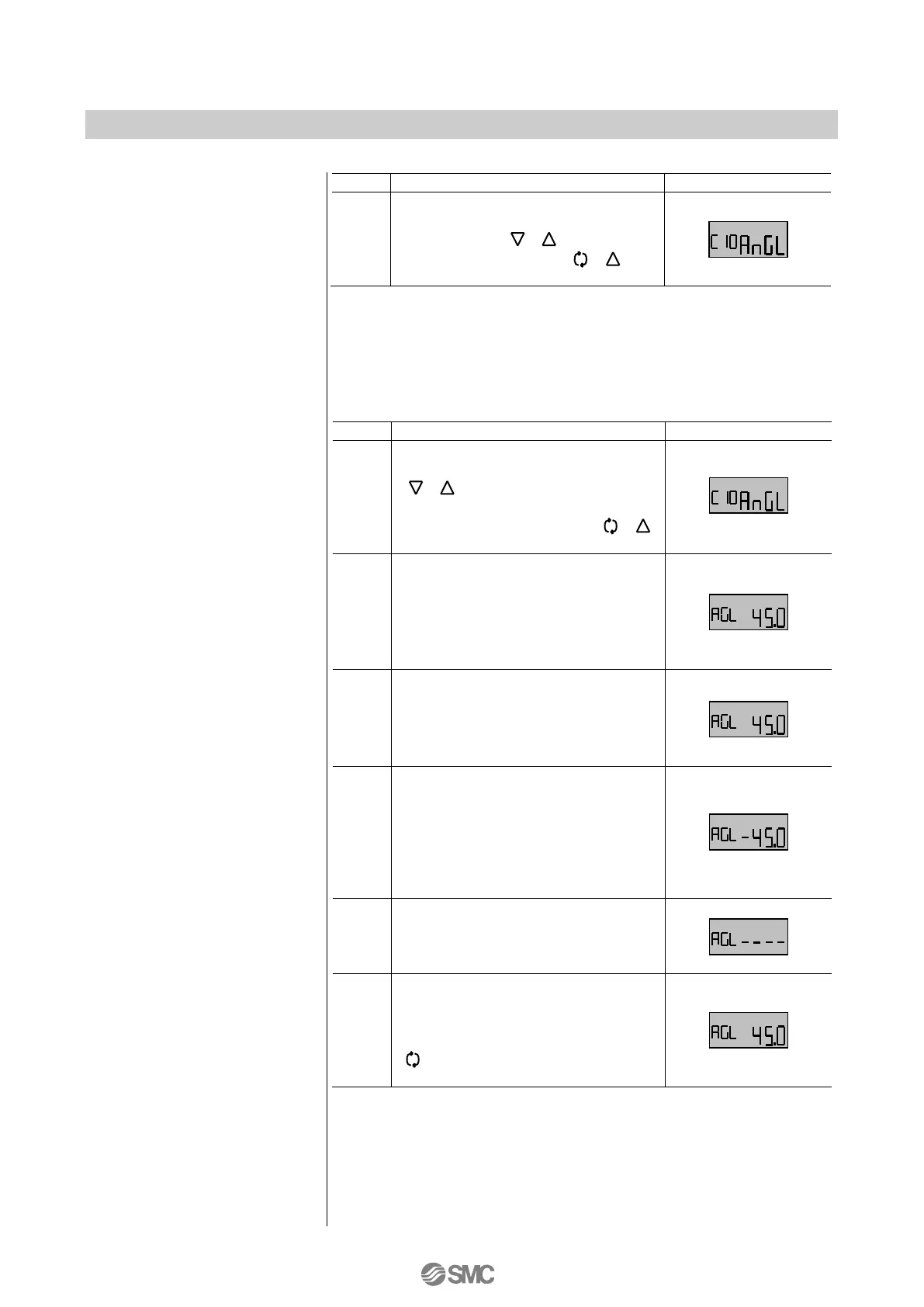

The output of OUT1 is 0MPa

*

5

and

the actuator is located at its end

position. Confirm the LCD displays

a number between –60 and +60,

and that there is no interference

between the actuator and body.

Rotate the pilot valve unit

auto/manual switching screw

approx. 1/8 turn to the manual side

paying attention to the actuator

rotation

*

6

.

OUT1 output reaches its maximum

and the actuator is located at its

end position opposite the one in

clause 2. Confirm the LCD shows a

number between –60 and +60, and

that there is interference between

the actuator and body.

If the LCD displays bars (----),

which means +/-60 is exceeded, at

both ends, readjust the fixed

position of the fork lever-type fitting.

After confirmation, rotate the

auto/manual switch screw to the

auto position and tighten it securely.

Then, keep pressing a mode button

( ) for 1sec. or more to return to

calibration mode selection screen.

Select the parameter used in

section 2 to 6 by pressing the Down

or Up button ( ) and holding

down the set button ( ) for

1sec or longer.

Loading...

Loading...