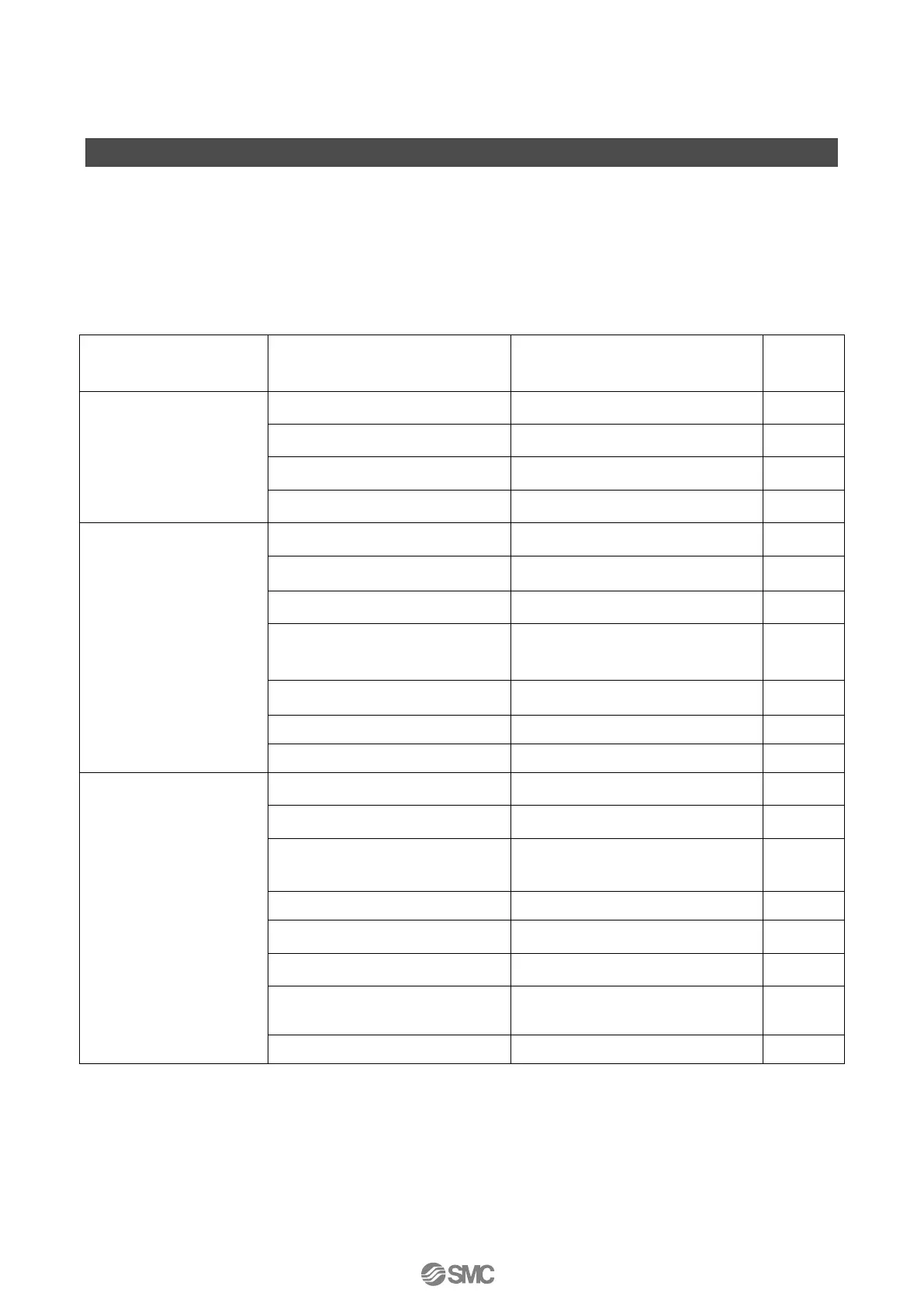

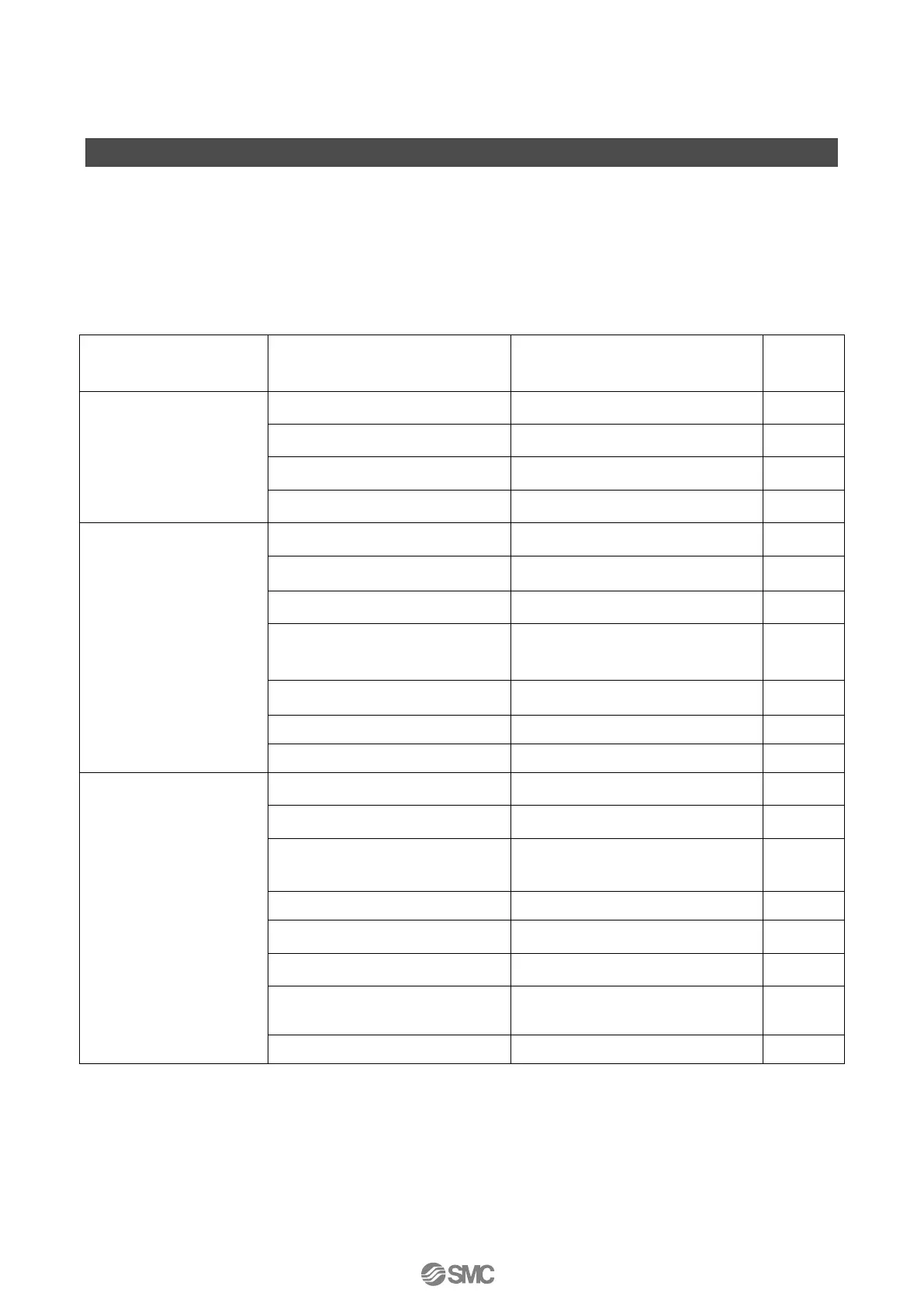

Troubleshooting, Error Code and Check Code

■Troubleshooting

If the positioner malfunctions, take countermeasures in accordance with the troubleshooting

measures listed in Table 15.

- Input current is disconnected.

-Check that wires are connected to

the positioner.

-There is no output from the input

current power supply.

-Check the output current of the input

current generator.

-An out-of-range input current power

is being supplied.

-Apply the correct input current power.

-Contact SMC representatives

(To check boards and etc.).

No air is output from the

OUT1 or OUT2 ports.

(Does not move at all.)

-Supplied pressure is incorrect.

-Check the supply pressure setting

of the regulator.

-No input current is being supplied.

-Apply the correct input current

(4 to 20 mADC).

-Air is leaking from the piping.

-Check the piping and fitting to stop

leaks.

-Operation mode is different.

-Change the operation mode(auto,

manual mode).

-Fixed orifice and nozzle are

clogged.

-Inspect and clean the pilot valve.

-Balance current is not adjusted.

-Adjust the balance current.

-Contact SMC representatives.

Low accuracy

(Linearity, hysteresis)

-Span adjustment has not been

performed.

-Perform the span adjustment.

-Dead band value is high.

-Change the dead band with the

parameter mode.

-Supply pressure is improper.

(Supply pressure is low)

-Check the regulator’s supply

pressure setting, set the proper

pressure per actuator.

-Supply pressure is fluctuating.

-Check the regulator supply pressure.

-Positioner mounting threads have

loosened.

-Ensure that the positioner mounting

threads have not loosened.

-Positioner and actuator are

improperly connected.

-Check the connection between the

positioner and actuator.

-Input current system is unstable.

-Adjust the input current system.

-Calibrate the input current with the

parameter mode.

-Contact SMC representatives.

Loading...

Loading...