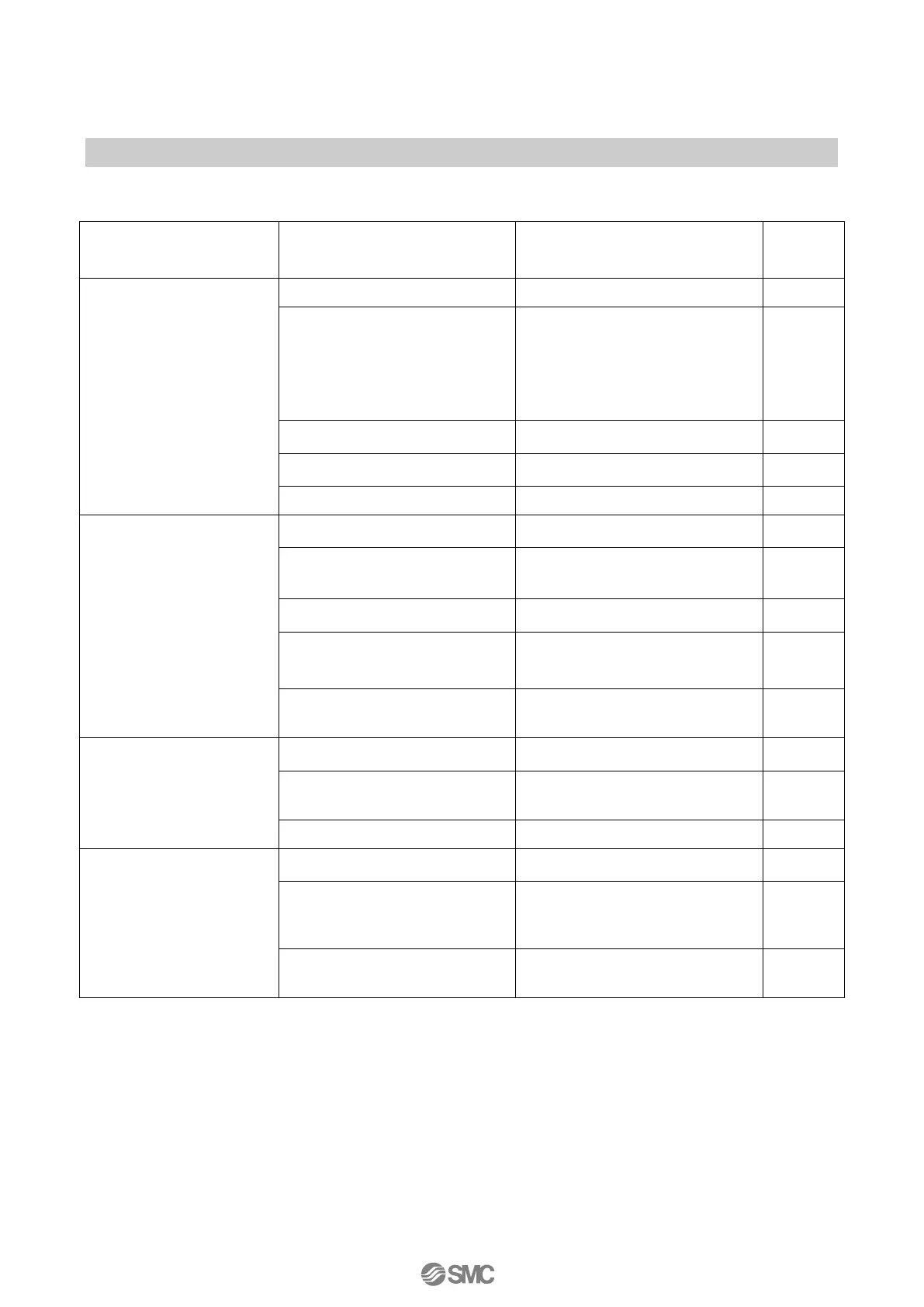

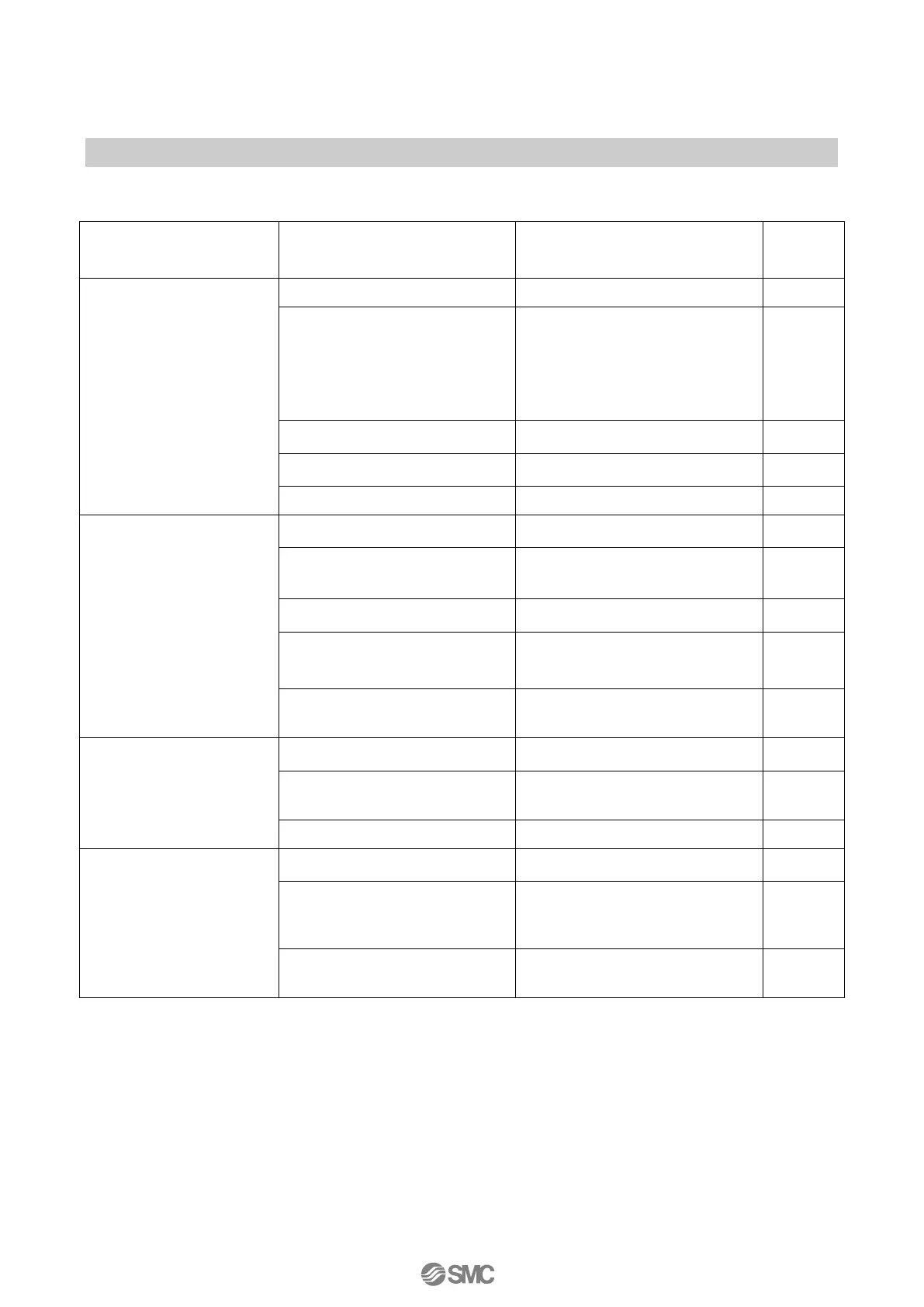

- Input current resolution is faulty.

- Check the input current system.

-Actuator’s sliding resistance is

large.

-Reduce the sliding resistance to as

little as possible.

-Operate only the actuator and check

the stick-slip movement. If this

movement cannot be recovered, it’s

beyond the capacity of this

positioner.

-Dead band value is high.

-Change the dead band with the

parameter mode.

-Operation takes time due to the

actuator’s large capacity.

-Wait until the actuator fills with air.

-Contact SMC representatives.

-Actuator is uncalibrated.

-Calibrate the actuator with the

parameter mode.

-PID constant after calibration is

improper due to use of a special

valve.

-Change the PID constant with the

parameter mode.

-There is play in the mounting of

the feed back shaft and actuator.

-Eliminate the play and properly

mount them.

-The input current itself is unstable.

-Check the input current system.

-Ground properly.

-Rotation resistance of the actuator

is significant due to ground and

piston packing.

-Reduce rotation resistance as much

as possible.

-Air is leaking from the piping.

-Check the piping, and stop

the leakage.

-Air is leaking from the positioner.

(due to a seating failure of the pilot

valve. )

-Replace the pilot valve unit.

-Contact SMC representatives.

Automatic calibration

is unavailable

- Fork lever fixing nuts are loose.

-Tighten fixing nuts after fork lever

angle has been adjusted.

-The angle of the fork lever is in

excess of –60/+60 degrees on

both ends of the actuator.

-Refer to “2, fork lever angle

adjustment” in “■Initial Adjustment”,

and securely adjust the angle to

+/-60degrees or less.

-The rotation angle of the actuator

is below 60 degrees or in excess

of 100 degrees.

-The standard positioner stroke is

from 60 to 100 degrees. Use it

within 60 to 100 degrees.

Loading...

Loading...