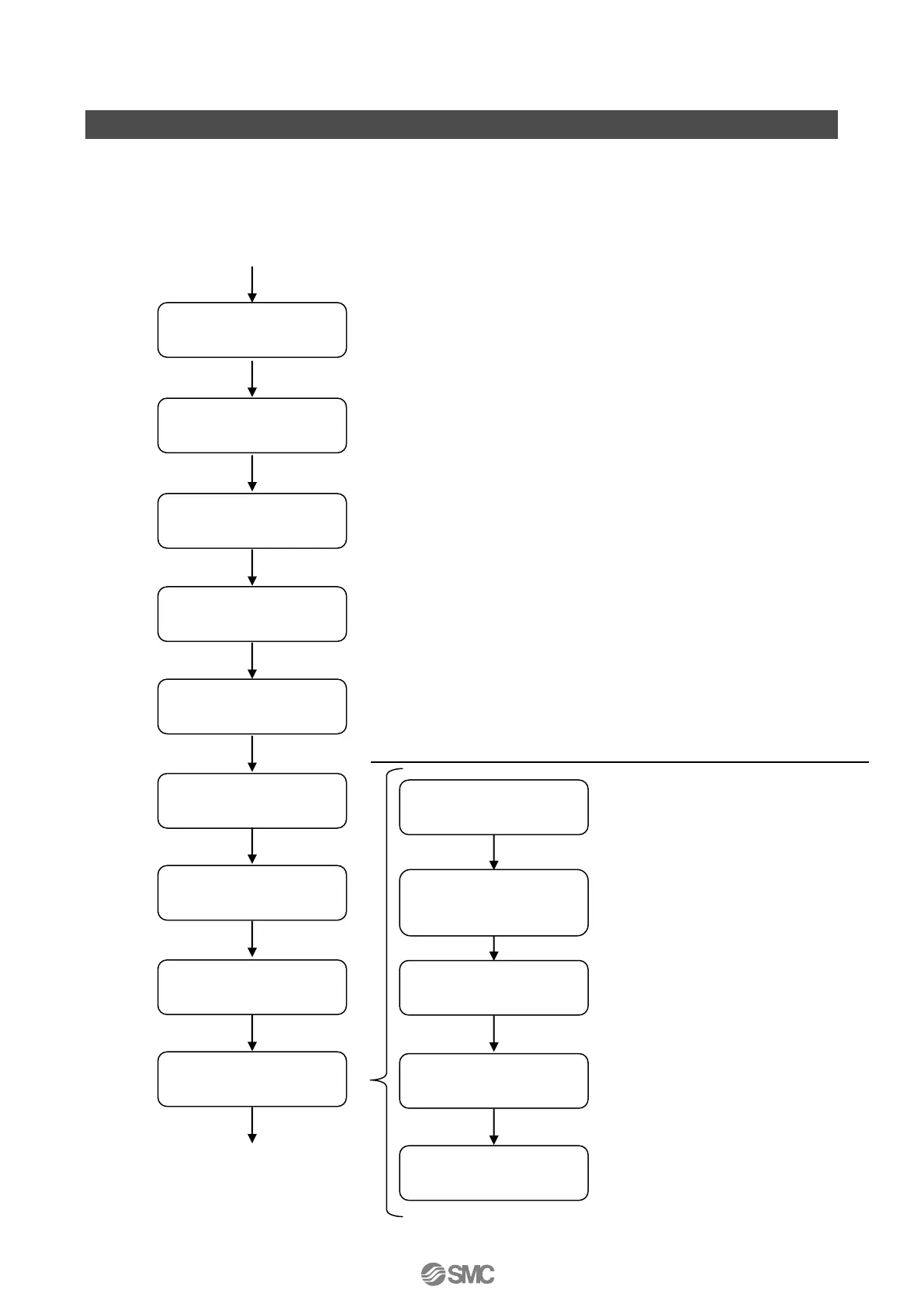

Workflow of IP8101 Positioner Setup

The workflow of IP8101 smart positioner from setup to initial adjustment is shown below. Follow this

flow when performing setups and adjustments of the positioner.

Check the specification and ensure the positioner is

suitable for the connected actuator and application.

1. Select calibration

mode

3. Simple balance

current adjustment

5. Calibration of input

current

With reference to “■Piping Layout”, select the

piping method suitable for the application.

Select the mode used for initial

adjustment.

Perform zero point/span adjustment

and PID constant settings suitable for

the connected actuator.

Perform calibration of the input

current as necessary. Normally, this

is not required.

With reference to “■Example of Mounting on

Actuator”, select the bracket suitable for the

application.

Adjust balance current simply.

Check each

part’s description

Check the contents on

the LCD display

Mount a fork

lever-type fitting

<Perform initial adjustment in the following order along with this manual>

With reference to “■Connection with Feedback

Shaft”, mount a fork lever-type fitting on the

actuator.

Connect the positioner to the actuator with the fork

lever-type fitting.

Set the angle of the fork lever-type

fitting as shown in “■Mounting”.

2. Set the angle of the

fork lever-type fitting

Loading...

Loading...