100

Make sure to load the provided black PLA filament into the left nozzle and the white

Breakaway PLA filament into the right nozzle, which is required to print the test model of

Snapmaker Luban in later sections.

If the filament has a bent or curled end, cut it off before loading.

To change the filament later, take the following steps:

1. Tap Control > Filament.

2. Select the target nozzle, set the temperature, and tap Heat.

3. When the heating completes, tap Unload and pull the filament out of the nozzle.

4. Insert the new filament into the module, and tap Load until the new filament extrudes successfully.

2. Z Offset Calibration & Heated Bed Leveling

Brief Introduction

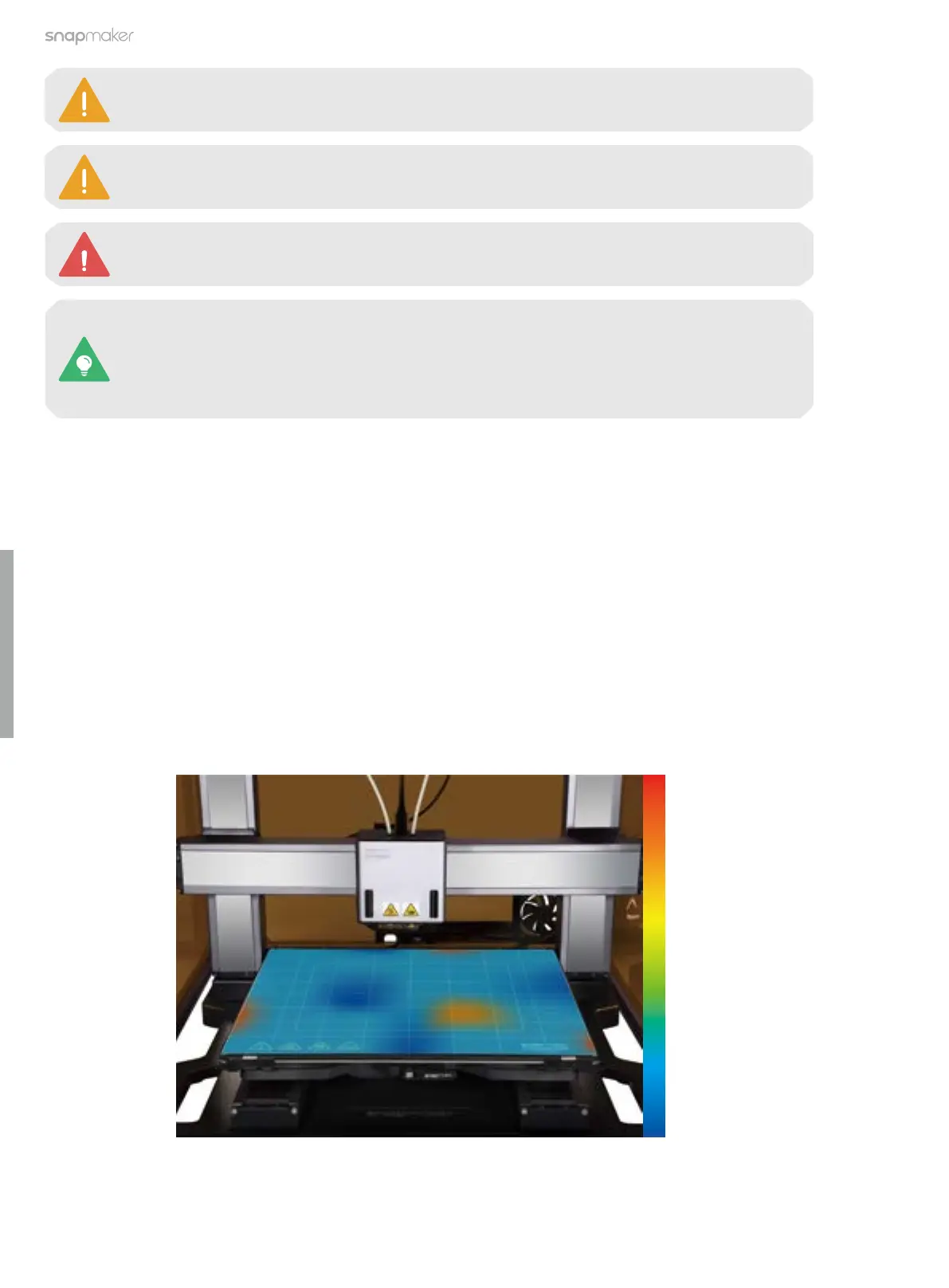

The Dual Extrusion Module features a smart sensor that can be used to automatically level the build plate and

adjust the distance between the two nozzles and the build plate. In this way, the machine ensures both nozzles

always extrude at a proper and consistent height throughout the printing process to avoid poor first-layer

adhesion, build plate abrasion, and collision.

How It Works

In the Z Offset Calibration, the two nozzles will move in turn to obtain the Z-axis height of the module when

the nozzle just touches the build plate. In the subsequent Heated Bed Leveling process, the left nozzle will

repeat the above steps at specific points on the build plate to obtain the whole flatness data. With the collected

data, the machine will make real-time compensation for the build plate undulations by adjusting the Z-axis

movements of the module during printing.

High

Low

(Build

Plate

Height)

Do NOT touch the nozzle with bare hands during the filament loading process, as the nozzle

will be heated to an extremely high temperature.

https://snapmaker.com/

Loading...

Loading...