37

12.3 Time sequences of operator lighting in normal mode and in case of faults

The flash sequences show information on malfunctions for technicians, end customers and telephone support.

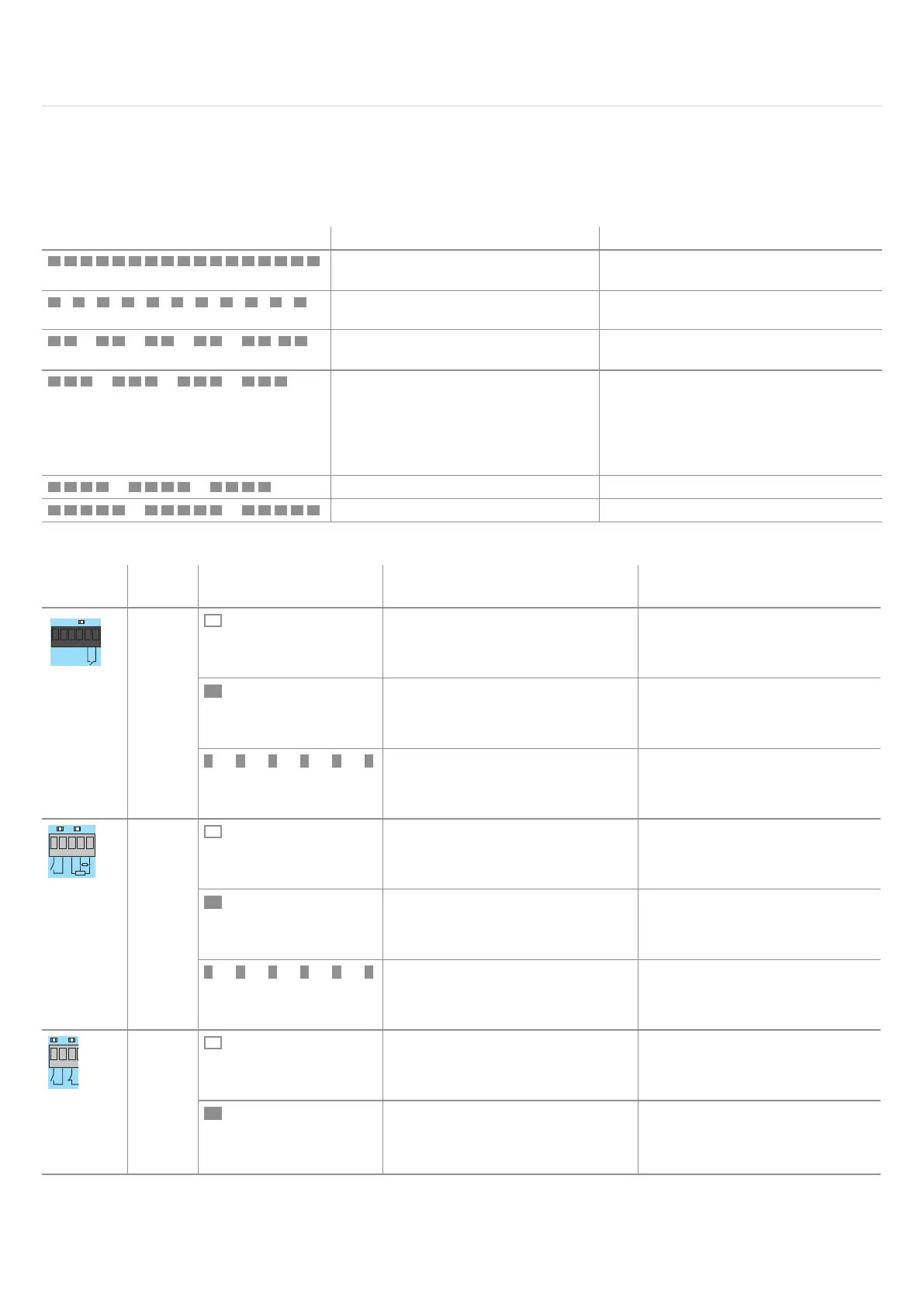

Integrated lighting as error display

Flash sequences Possible cause Corrective action

• Photocell interrupted/defective • Remove obstacle

• Repair/replace photocell

• Door moves in CLOSE/OPEN

direction

• No action required

• Safety contact strip triggered/

defective

• Remove obstacle

• Repair/replace safety contact strip

• Programmed motor run time

exceeded

• Check that the roller door runs

smoothly: repair/replace if necessary

• Check limit switch of tubular motor:

repair/replace if necessary

• Check tubular motor: repair/replace

if necessary

• Locking mechanism triggered • Repair/replace locking mechanism

• Hardware error on circuit board • Replace control unit

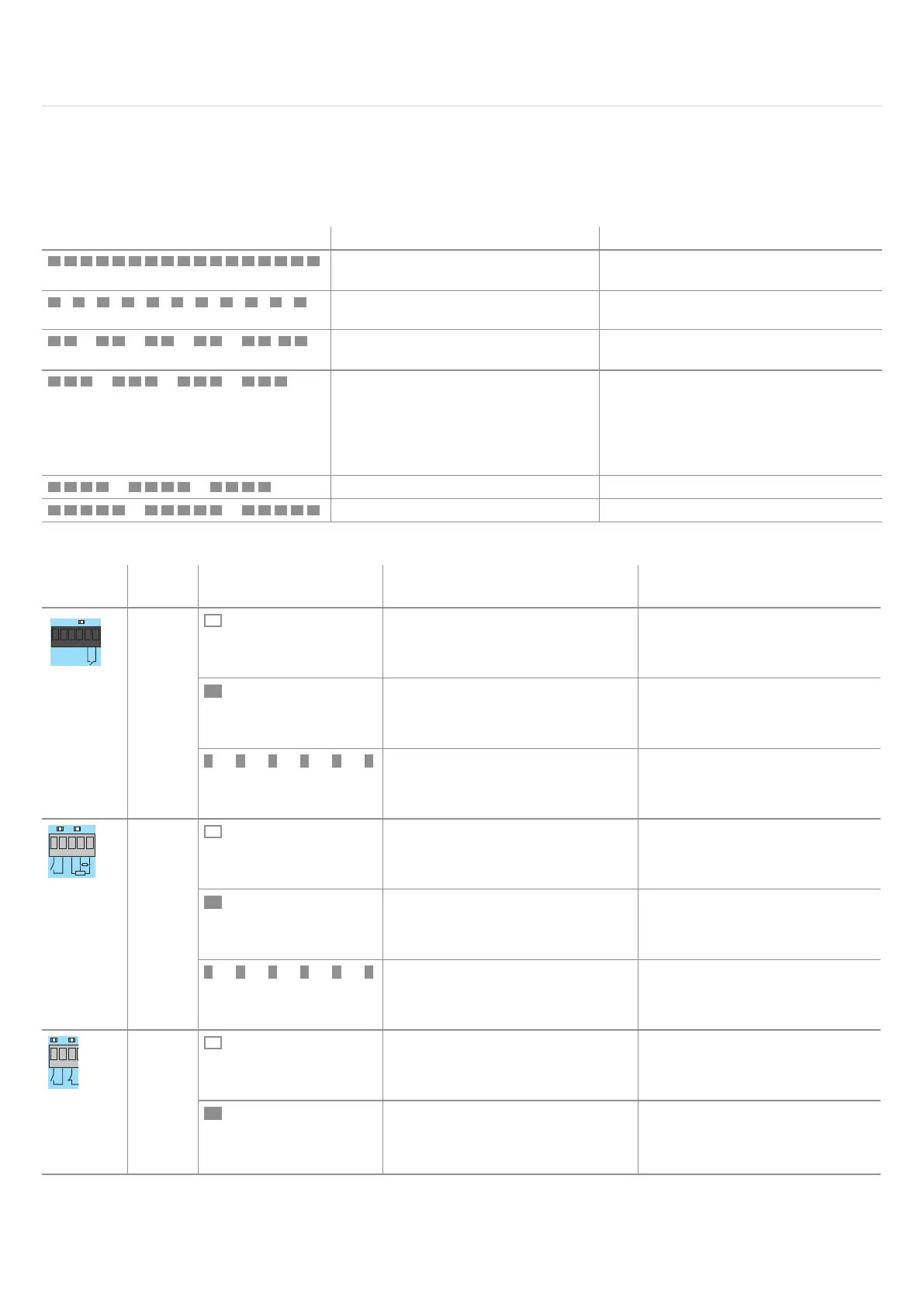

LEDs on board

LED Colour Flash/illumination

sequences

Possible cause Corrective action

24V

GND

24V

GND

SIGNAL

COM

Orange

O

• No photocell detected • Connect a photocell if necessary

On

• Photocell detected • No action required

• Photocell triggered/fault • Remove obstacle

• Repair/replace photocell

VES

8K2

gn

wh

OSE

Yellow

O

• Pre-end position switch not

detected

• Connect pre-end position switch

On

• Safety contact strip detected • No action required

• Pre-end position switch triggered

• Safety contact strip triggered/

defective

• Repair/replace safety contact

strip

IMP

Yellow

O

• No external command pending

• Locking mechanism OK

• Activate external command

device

• No action required

On

• External command pending/button

defective

• Locking mechanism triggered/

defective

• Enable/replace external

command device

• Replace locking mechanism

12. Troubleshooting

Loading...

Loading...