44

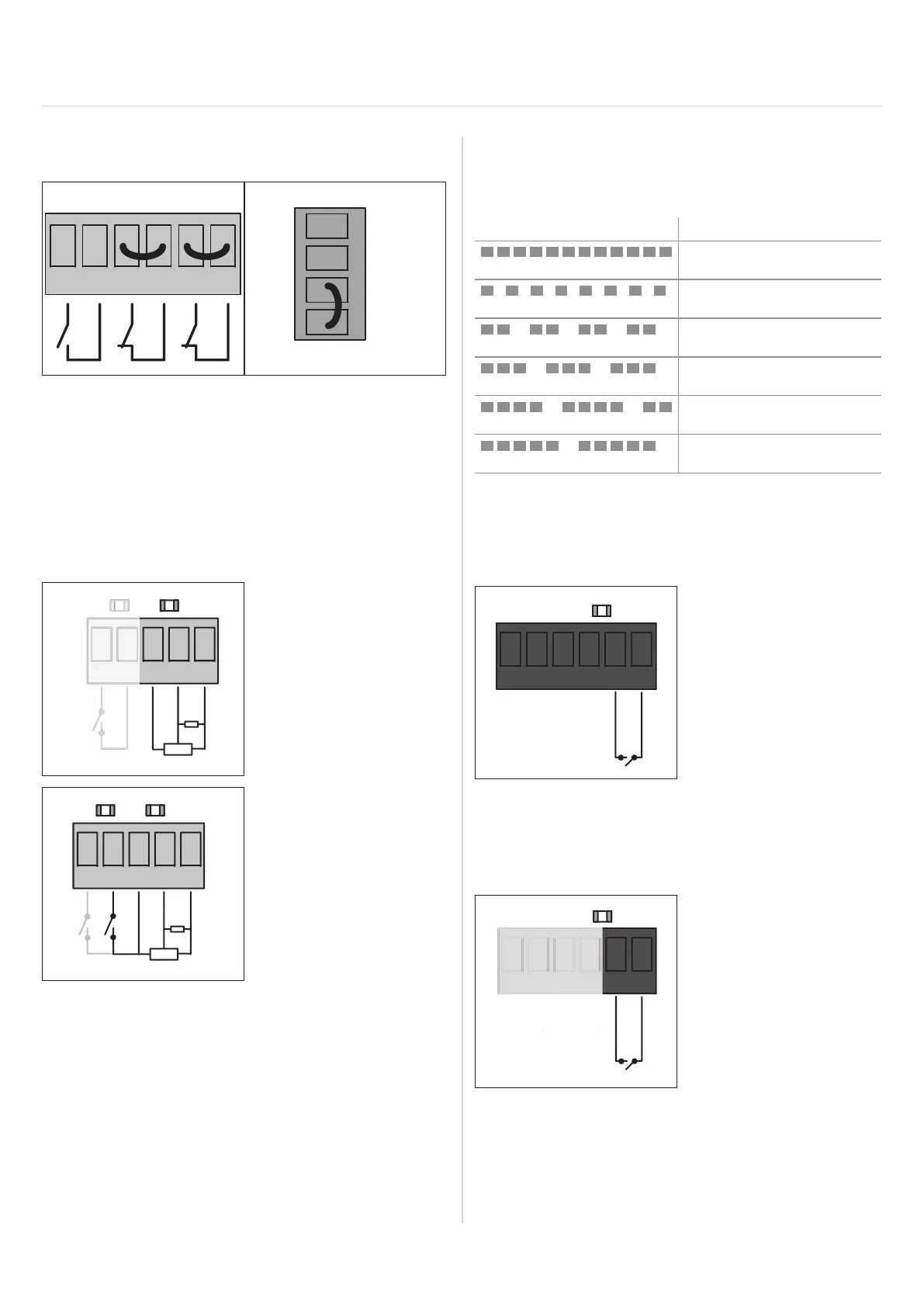

14.3 Checking the wiring of any

unused inputs

IMP

ARS

STOP

CLOSE

OPEN

STOP

COM

The following terminal pairs must be connected to each

other with wire jumpers or normally closed (NC) contacts:

• Locking mechanism

• STOP button

• STOP button of the

external command device

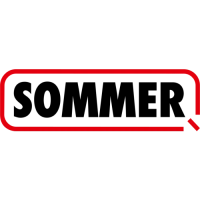

14.4 Connecting a safety contact strip

(8K2 or OSE)

+12 V

VES

8K2

gn

bn

12V

wh

OSE

VE

VES

8K2

gn

bn

12V

wh

OSE

ye

Connection of OSE or 8k2 with pre-end position switch at 4-wire

spiral cable

► No settings need to be made on the control unit. The

control unit tests and recognises which safety contact

strip variant is connected during each self-test (when

the mains voltage is switched on or an end position

has been reached).

14. Brief instructions

► Fortestpurposes,the8.2kΩresistorincludedinthe

scope of delivery can be connected to the terminals

of terminal strip X5. See “8.5 Setting the run time

(run time monitoring)” on page 23 . If the LED on

the safety input still blinks, consult the table below:

Flash sequences Possible cause

• Photocell interrupted/

defective

• Door moves in CLOSE/

OPEN direction

• Safety contact strip

triggered/defective

• Programmed motor run

time exceeded

• Locking mechanism

triggered

• Hardware error on circuit

board

Integrated lighting

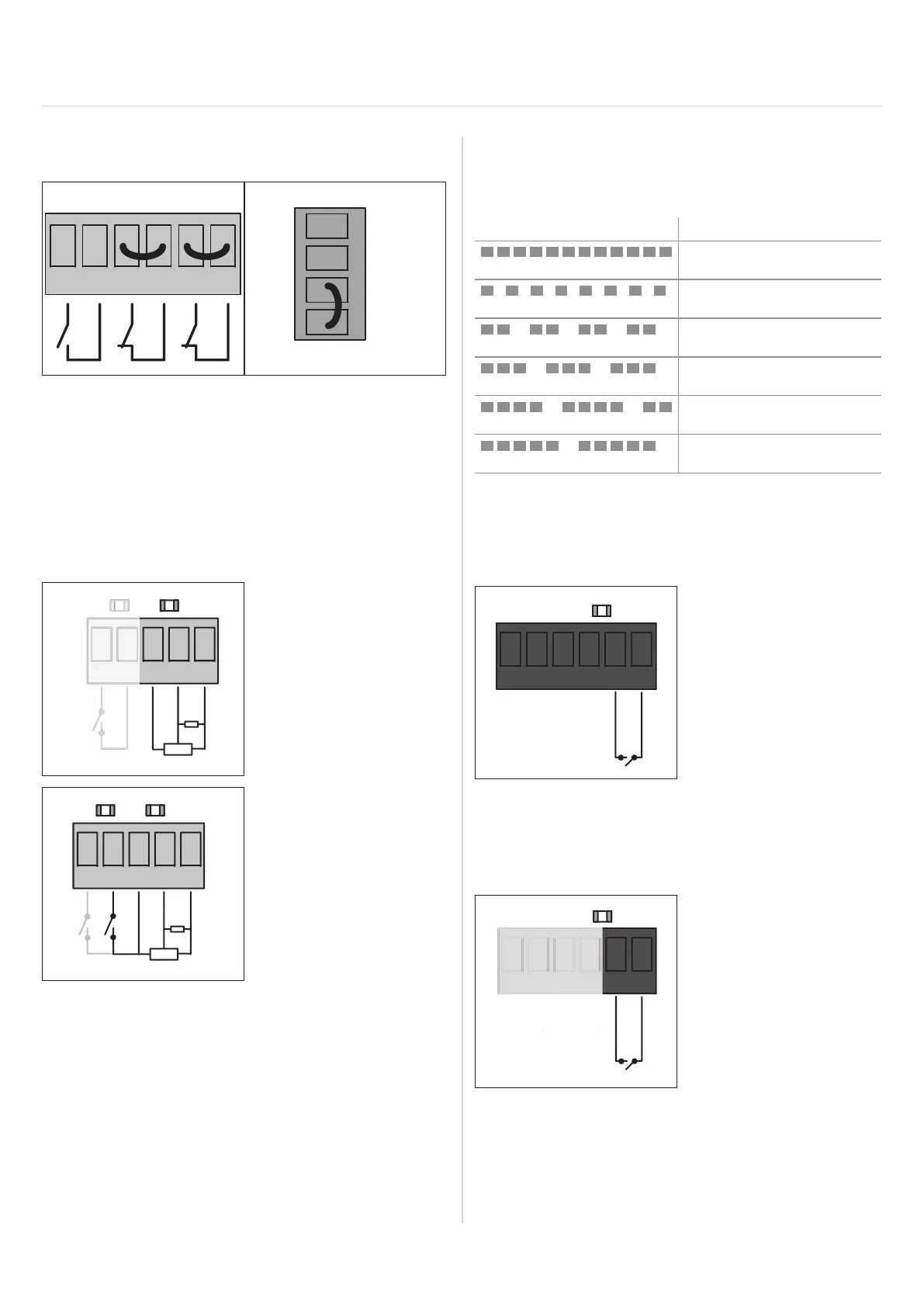

14.5 Connection of one-way photocell

with potential-free relay contact

(NC)

24V

GND

24V

GND

SIGNAL

COM

X4

* The control unit provides a total of max. 300 mA / 7 W for all 24 V

consumers

14.6 Connection of 2-wire frame

photocell

24V

GND

24V

GND

SIGNAL

COM

N

N

X4

Loading...

Loading...