— 05.12.2017 —

7 Maintenance

Information

In order to ensure the

availability and operational safety of the equipment, we

recommend having the system checked for correct operation and performance at

least once per year by specialized technicians. To find contact addresses of

service organizations authorized by SPECTRO g

o to www.spectro.com

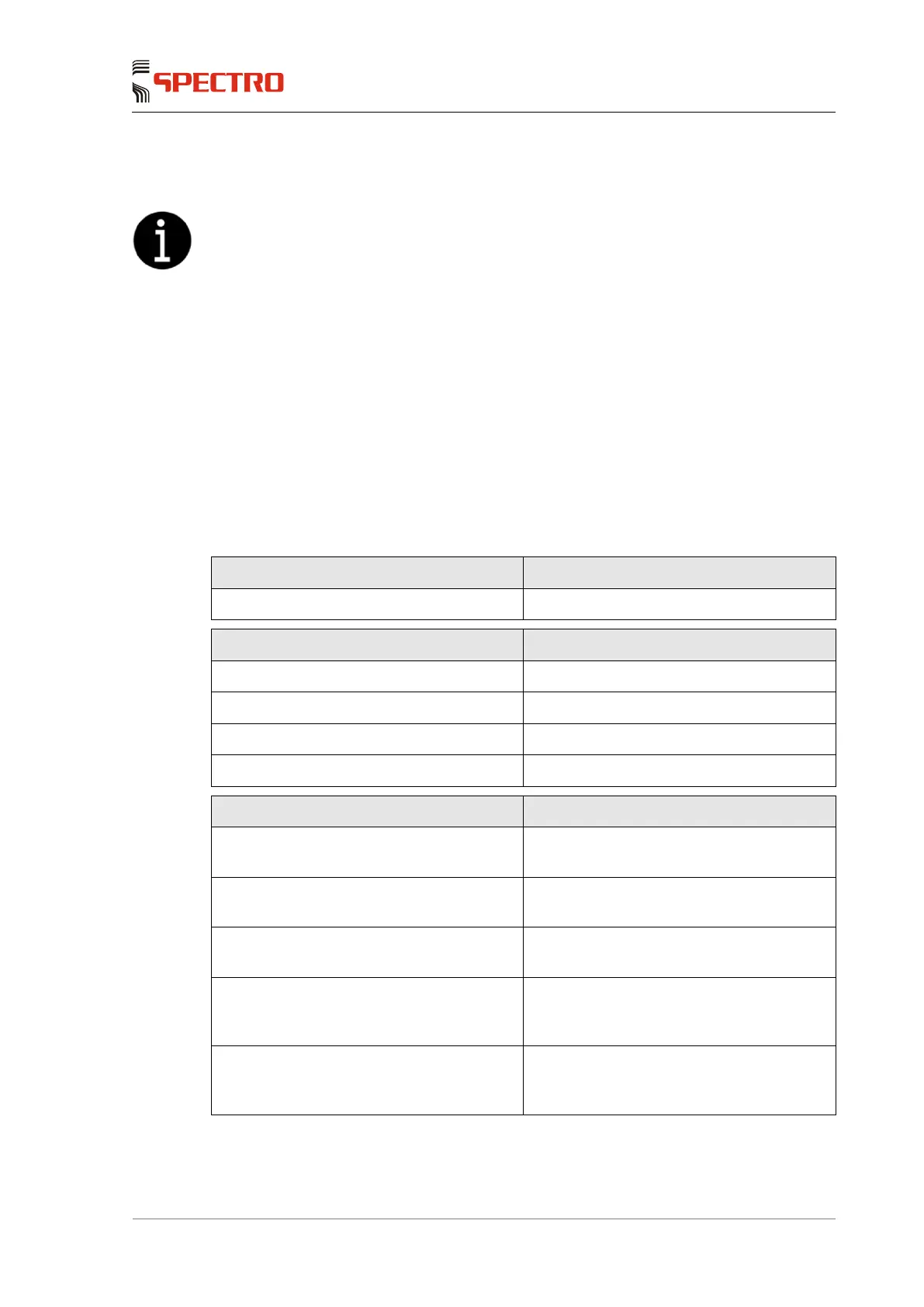

7.1 Maintenance schedule

The maintenance intervals specified in the following table are guidelines which

should be observed as a minimum requirement. The maintenance intervals may

vary, depending on the use of the instrument.

To ensure the flawless function of the instrument, proceed with the following

maintenance tasks:

After every measurement Necessary tasks

Cleaning the electrode Clean the electrode with a small wire brush.

Start of work Necessary tasks

Checking the argon supply Min. pressure in bottle: 10 bar.

Cleaning the adapter See page 32.

Checking the focal spot Visual inspection

ICALization See page 27.

As required

Cleaning the windows of the sample probe

and of the adapter

See page 32.

Cleaning the air filter (housing)

Every month or more often if necessary See

page 34.

Replacing the air filter (sample probe)

Every month or more often if necessary See

page 35.

Fine dust filter unit Replace every six months or more

frequently if necessary (the system will

display a message) See page 36.

CO

2

filter unit

Replace every six months or more

frequently if necessary (the system will

display a message) See page 36

Loading...

Loading...