11-33

If the coolant becomes very dirty, replace it immedi-

ately regardless of the specified replacement inter-

vals.

1 Recommended coolant

Use a coolant containing fully-formulated antifreeze

and soft water in the correct mixing ratio.

This solution provides corrosion inhibitors to protect

the cooling system.

Replace the coolant, and top it off when necessary,

only with water containing fully-formulated anti-

freeze with corrosion inhibitors.

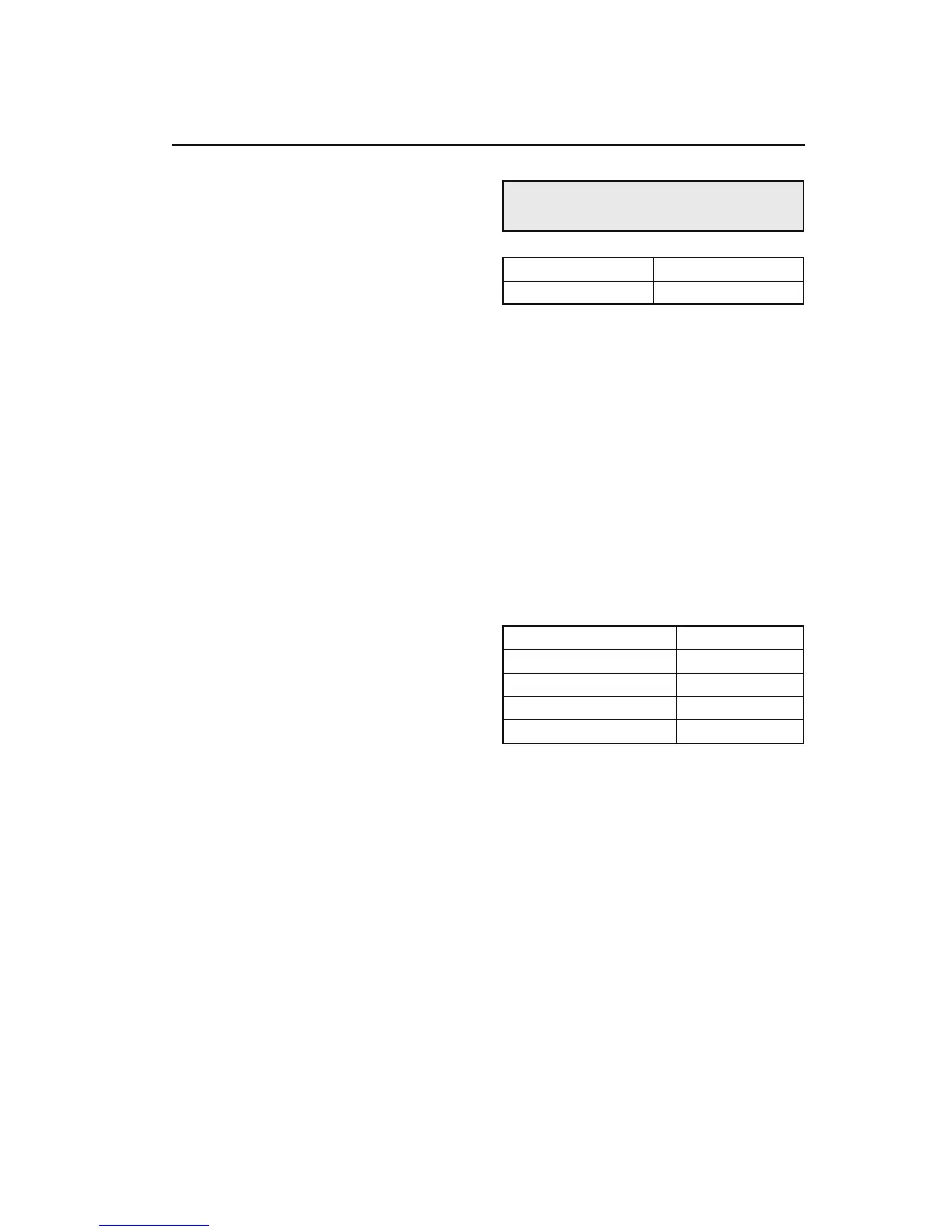

2 Water used with coolant

Use soft water with the properties shown in the fol-

lowing table. Do not use hard water from wells and

rivers as it is liable to form scale and cause corro-

sion.

3 Using coolant additive

To prevent the cooling system from freezing and to

minimize corrosion, use a fully-formulated anti-

freeze with an ethylene glycol base (SAE J814-C),

an antifreeze with corrosion-inhibiting properties.

Dilute it with soft water to the specified concentra-

tion.

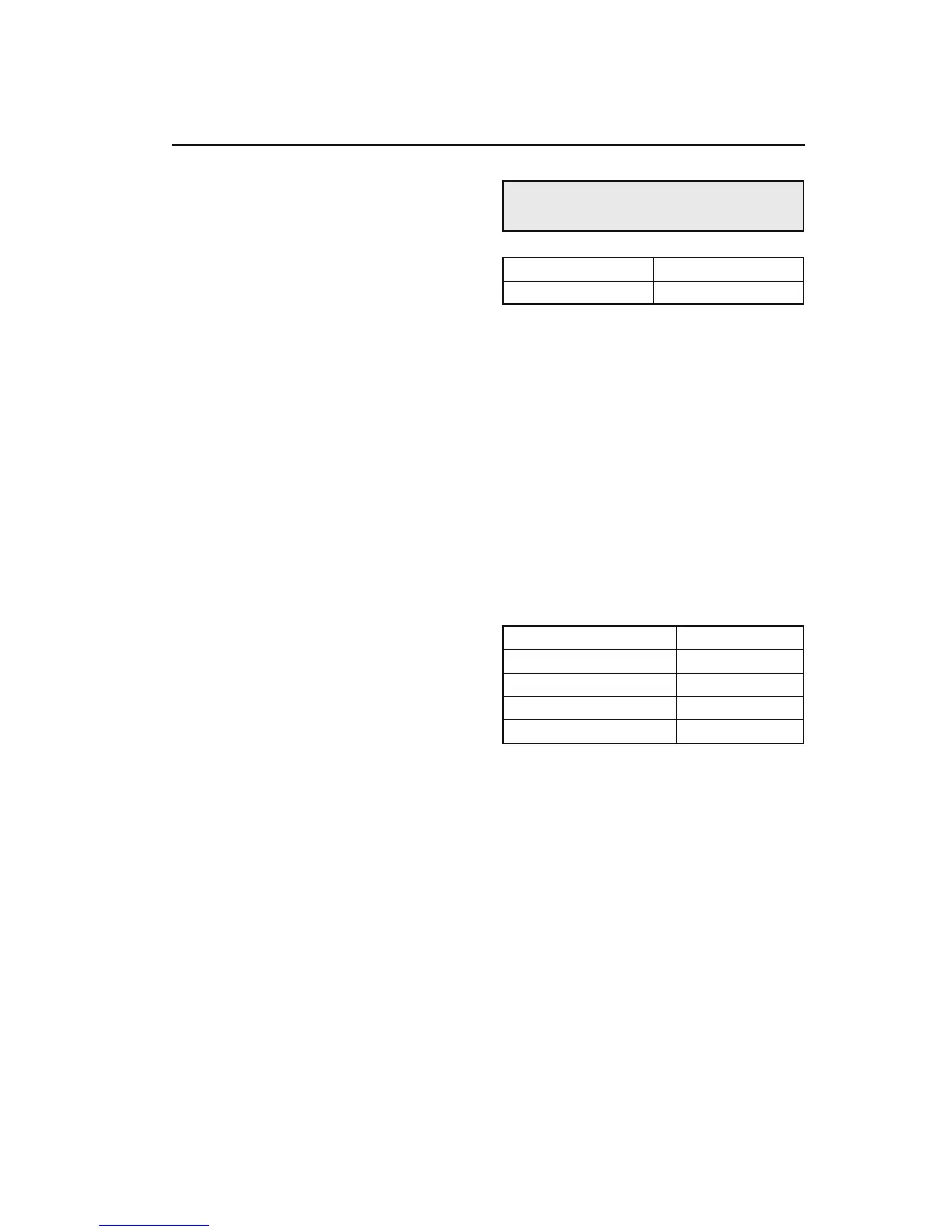

Coolant checking and

replacing

Inspection interval Daily pretrip inspection

Replacement interval Every 24 months

Total hardness 300 ppm or less

Sulfate SO

4

–

100 ppm or less

Chloride Cl

–

100 ppm or less

Total dissolved solids 500 ppm or less

pH 6 to 8

Loading...

Loading...