11-39

An excessively loose or tight belt could cause the

engine to overheat, the battery to be inadequately

charged, or the alternator or water pump to mal-

function. Always keep the belt adjusted to the

proper tension.

CAUTION

Do not allow the drive belt to come in contact

with oil or grease during this procedure.

If soiled with oil or grease, the belt will slip,

shortening its service life.

1Check

1. Set the parking brake and chock the front tires.

Tilt the cab. P. 11-4

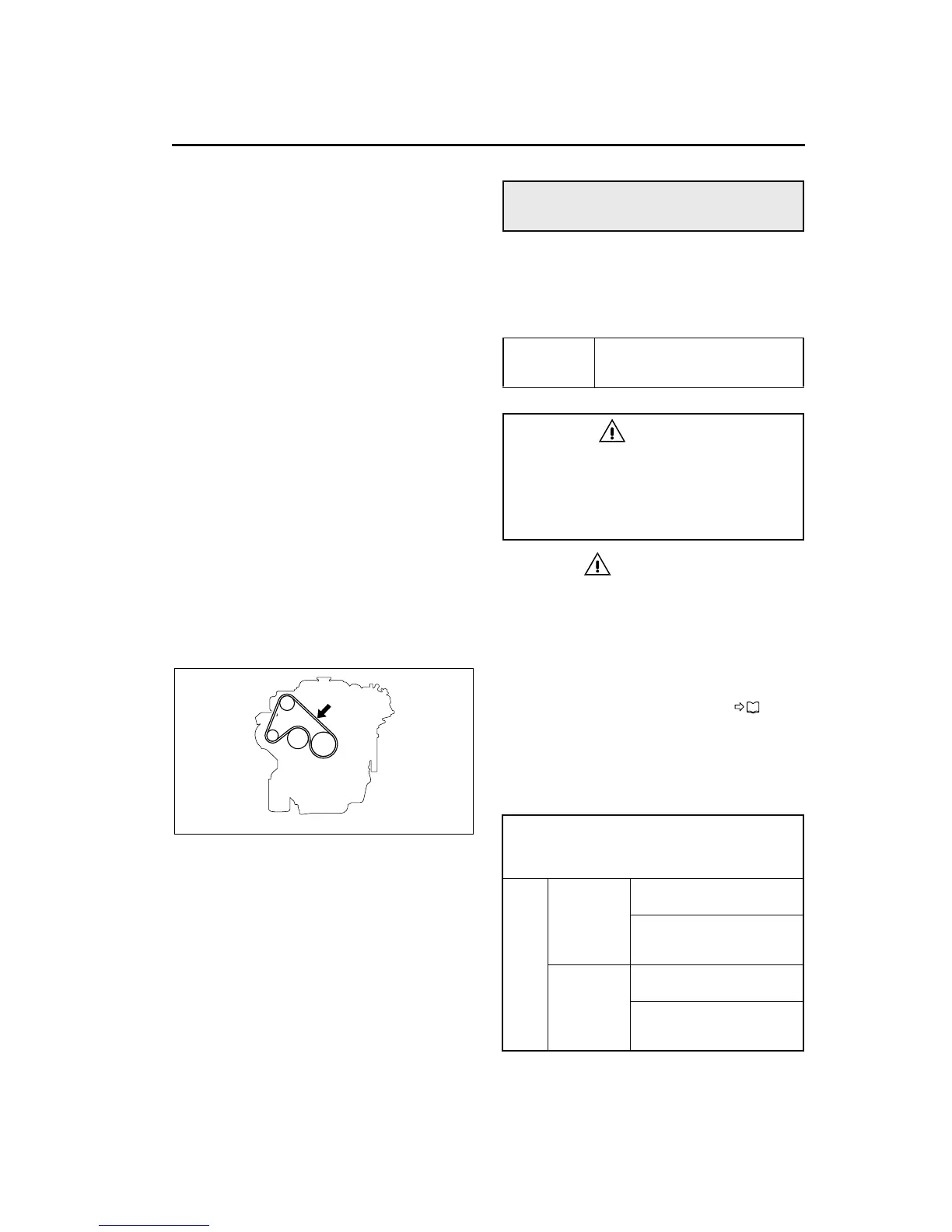

2. Press the belt with a force of around 22 lb (98 N)

at the point midway between the pulleys, and

measure the amount of deflection.

3. If necessary, adjust the belt tension until the belt

deflection is within the limits given in the table

below.

4. Check the belt for damage. Replace the belt if

damage is found.

Drive belt checking and adjusting

Inspection

intervals

Daily pretrip inspection and

every 6000 miles (10 000 km)

or every 12 months

WARNING

Always shut down the engine before inspect-

ing or adjusting belts. A moving drive belt

can cause a serious injury or loss of life.

Ensure that the engine cannot be started

while you are performing checks or adjust-

ments.

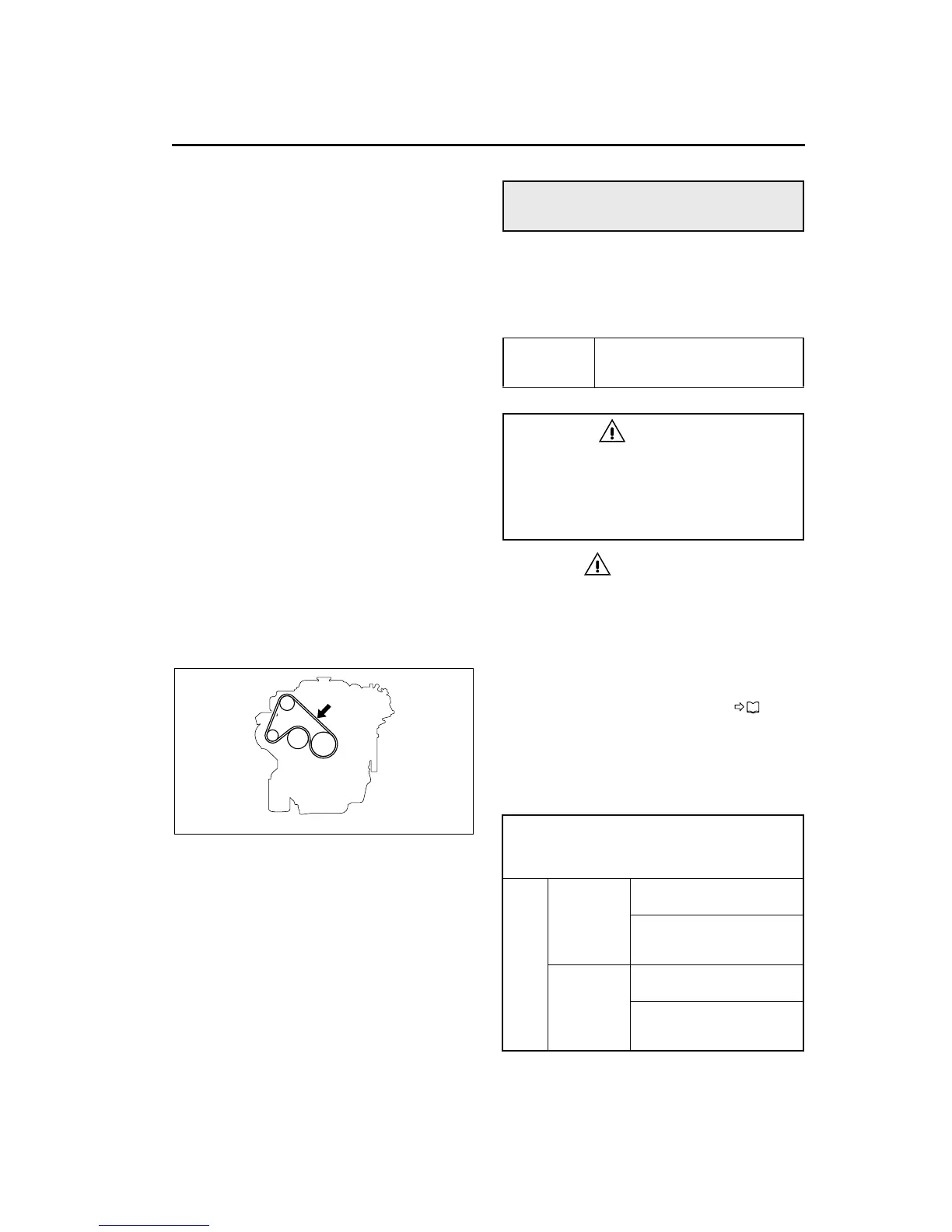

Belt tension

[Amount of deflection when the belt is pressed

with a force of 22 lb (98 N) at the point

midway between the pulleys]

Drive

belt

Vehicles

without air

conditioner

New belt (when installed):

0.35 to 0.43 in (9 to 11 mm)

Used belt (when inspected

or reinstalled): 0.43 to 0.51

in (11 to 13 mm)

Vehicles

with air

conditioner

New belt (when installed):

0.28 to 0.35 in (7 to 9 mm)

Used belt (when inspected

or reinstalled): 0.39 to 0.43

in (10 to 11 mm)

Z11933

Loading...

Loading...