11-42 Pretrip inspection and maintenance

1. While driving slowly, make sure that the steering

wheel does not shake and the vehicle does not

pull to one side. The wheel should turn easily,

without excessive operating resistance, and

return smoothly to the neutral position.

2. If any problem is found, call an authorized Ster-

ling service facility for inspection.

The service brakes are critical to vehicle safety. If

an inspection reveals any problem, contact an

authorized Sterling service facility to solve the prob-

lem.

1 Brake pedal free play

1.1 <COE 40, 45: vacuum pressure booster>

1. Shut down the engine.

2. Set the parking brake and chock the rear tires.

3. On vehicles with a manual transmission, make

sure that the shift lever is in neutral.

On vehicles with an automatic transmission,

make sure that the shift selector is in “P” (park).

4. Pump the brake pedal several times to release

all the vacuum from the brake system (zero vac-

uum).

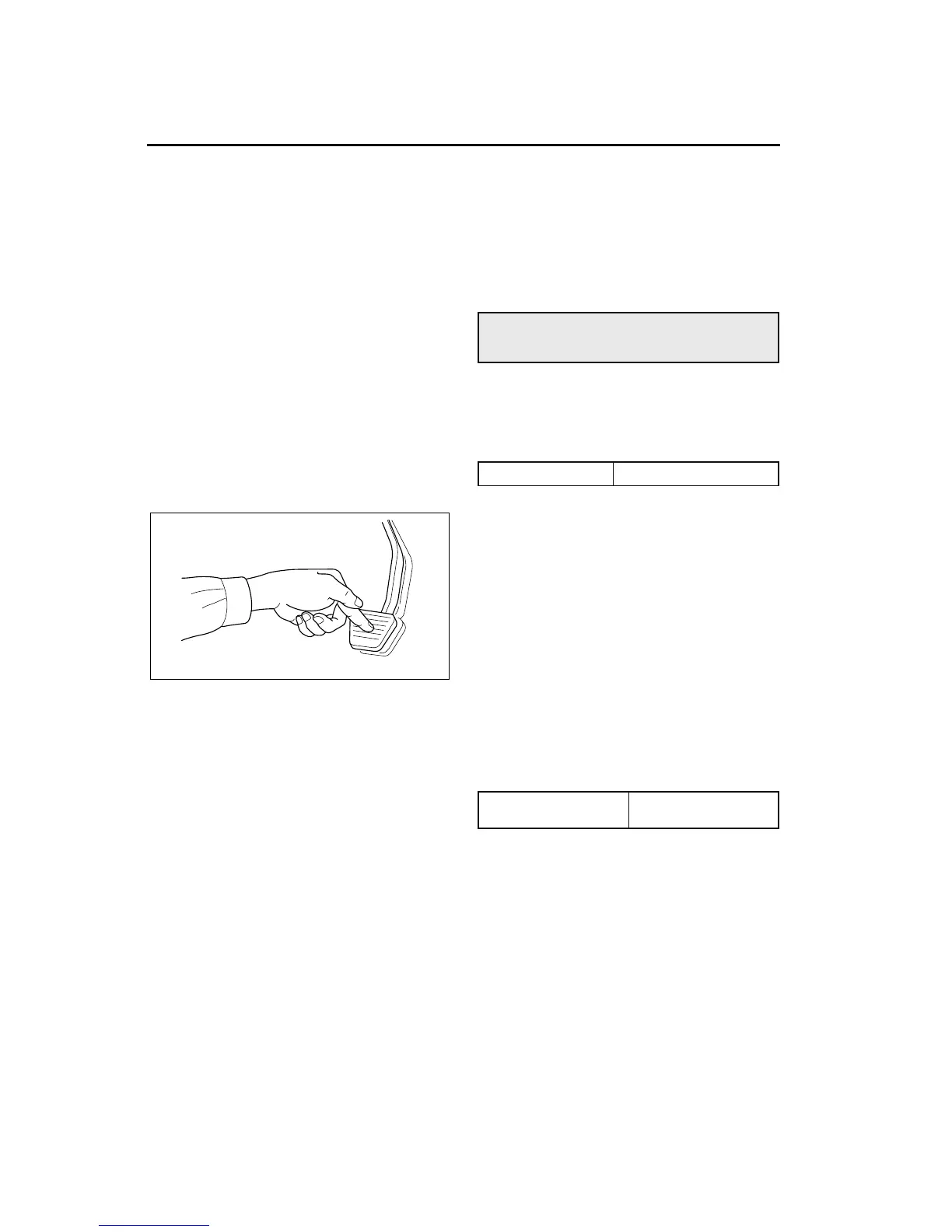

5. Press down with one finger on the center of the

pedal pad to the point where resistance is felt.

6. Measure the amount of brake pedal movement

between these two points. This is the brake

pedal free play. If the free play is not within

these limits, contact an authorized Sterling ser-

vice facility.

1.2 <COE 50: hydraulic brake booster>

1. Shut down the engine.

2. Set the parking brake and chock the rear tires.

3. On vehicles with a manual transmission, make

sure that the shift lever is in neutral.

On vehicles with an automatic transmission,

make sure that the shift selector is in “P” (park).

4. Press down with one finger on the center of the

pedal pad to the point where resistance is felt

(the electric motor will come on).

5. Measure the amount of brake pedal movement

between these two points. This is the brake

pedal free play. If the free play is not within the

limits given in the table above, contact an autho-

rized Sterling service facility.

Service brake checking

Inspection interval Daily pretrip inspection

Brake pedal free play

(at center of pedal pad)

0.004 to 0.118 in

(0.1 to 3.0 mm)

Z09288

Loading...

Loading...