S - 108 | English English | S - 109

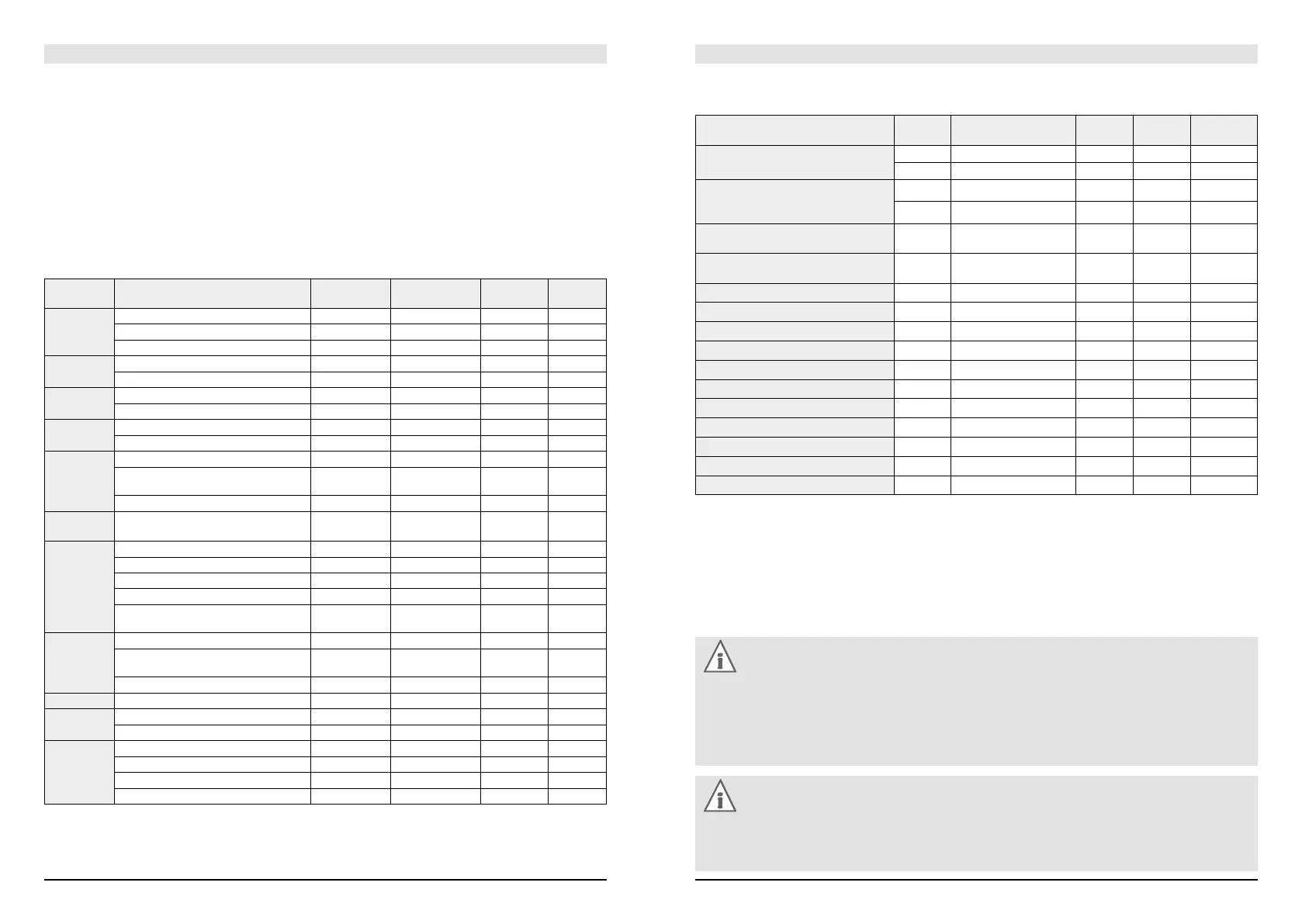

Recommended Torque Settings

All bolted connections of the bicycle components have to be tightened carefully and checked regularly to ensure

the safe and reliable operation of your STEVENS bicycle. This is best done with a torque wrench that disengages at

the desired torque value or a click-type torque wrench. Tighten carefully by approaching the prescribed maximum

torque value in small steps (0.5 Nm increments) and check in between the proper fit of the component. Do not

exceed the maximum torque value indicated by the manufacturer!

Where no maximum torque value is given start with 2Nm. Observe the indicated values and observe the values

on the components themselves and/or in the instructions of the component manufacturers.

Component Bolted connections Shimano

1

(Nm)

SRAM/Avid

2

(Nm)

Tektro

3

(Nm)

TRP

4

(Nm)

Rear

derailleur

Mount (on frame/derailleur hanger) 8–10 8–10

Cable clamp 5–7 4–5

Pulley wheels 3–4

Front

derailleur

Mount on frame 5–7 5–7

Cable clamp 5–7 5

Shifter Mount on handlebars 5 2.5–4

Hole covering 0.3–0.5

Brake lever

unit

Mount on handlebars 6–8 5–7 6–8

Time trial brake lever 5–7

Hub Quick-release lever 5 –7. 5

Locknut for bearing adjustment of

quick-release hubs

10–25

Sprocket cluster lock ring 29–49 40

Internal gear

hub

Axle nut 30–45

Crank Crank mount (grease-free square-head) 35–50

Crank mount (Shimano Octalink) 35–50

Crank mount (Shimano Hollowtech II) 12–15

Crank mount (Isis) 31–34

Chainring mount 8–11 12–14 (steel)

8–9 (alu)

Sealed

cartridge

bearing

Shell (square-head) 49–69

Shell

(Shimano Hollowtech II, SRAM Gigapipe)

35–50 34–41

Octalink 50–70

Pedal Pedal axle 35

Shoe Cleat 5–6

Spike 4

Brake

(V-brake)

Cable clamp 6–8 6–8 6–8 6–8

Brake shoe mount 6–8 6–8 6–8 6–8

Brake pad fixing 1–2

Brake boss frame/fork 8–10

1

si.shimano.com

2

sram.com

3

tektro.com

4

trpbrakes.com

Note:

Due to the unmanageable number of components on the market, STEVENS is not in a position to foresee

every product that will be replaced or newly assembled by third parties. Therefore STEVENS denies any

liability for such kind of additions or modifications with regard to compatibility, torque values etc. Whoever

assembles or modifies the STEVENS bicycle shall ensure that the bicycle is assembled according to the

state-of-the-art in science and technology.

Note:

Some components have the maximum permissible torque values printed on them. Use a torque wrench

and do not exceed the maximum torque values! If you are in doubt or if you have any questions, contact

your STEVENS dealer.

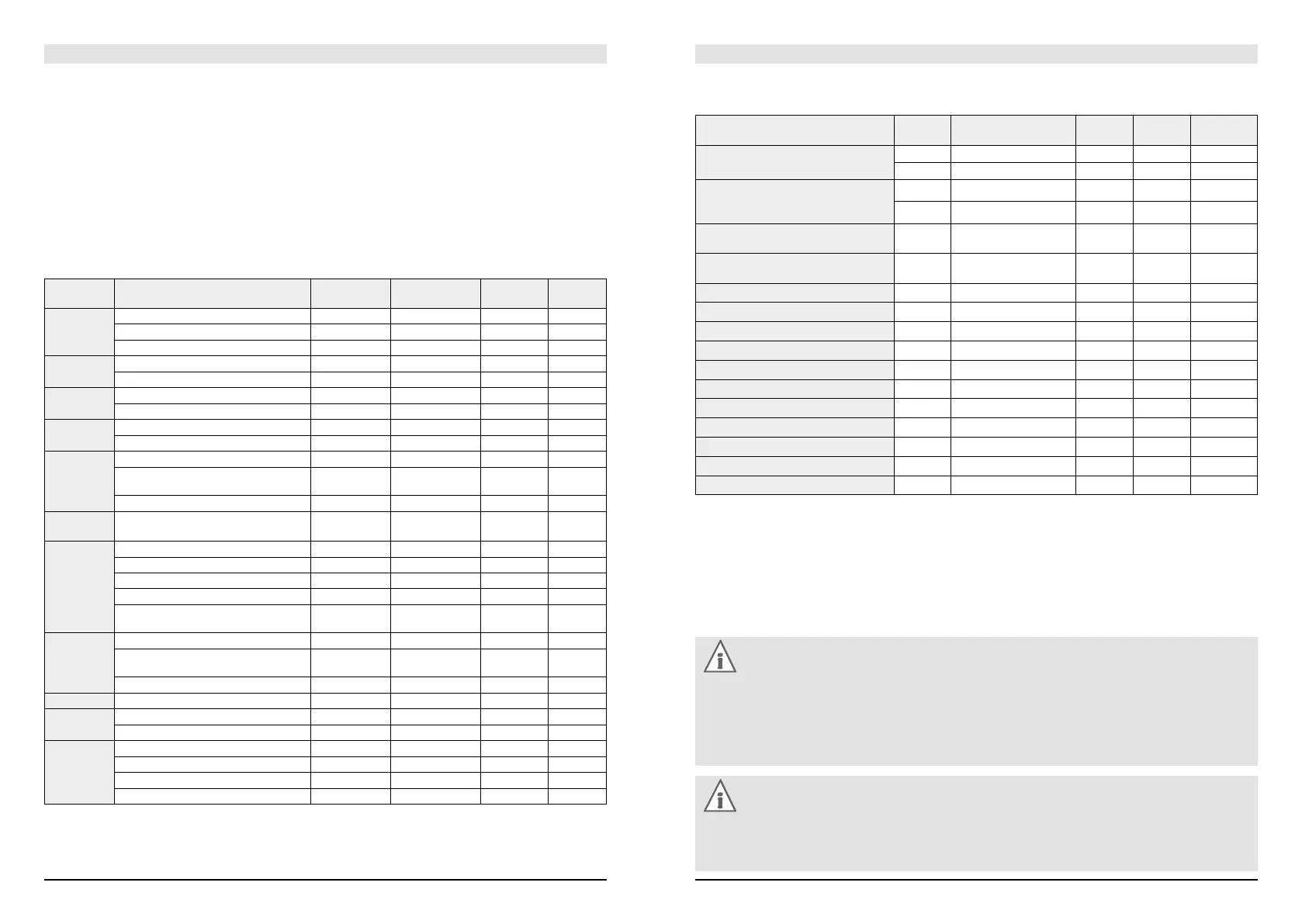

Recommended Torque Settings for Disc Brakes and Hydraulic Rim Brakes

Component Shimano

1

(Nm)

Avid

2

(Nm)

Tektro

3

(Nm)

TRP

4

(Nm)

Magura HS

5

(Nm)

Brake calliper mount on frame/fork 6–8 9–10 (IS-Adapter) 6–8 6–8 6

8–10 (brake calliper)

Brake lever unit on handlebar

– Single-bolt clamp

– Two-bolt clamp

6–8 5–7 4

7 (carbon)

Union screws of hose at grip

and normal hose at brake calliper

5–7 5 4

Brake hose connector at

brake calliper (disc tube hose)

5–7

Expansion tank cap 0.3–0.5

Bleeding device brake calliper 4–6 4–6

Bleeding device brake lever 2–4

Brake rotor fixing (6-holes) 4 6.2 4–6 6–8

Brake rotor fixing (Centerlock) 40

Hose (union nut) direct connection 5–7 5–7

Slave cylinder (bleeder screw) 4–6 4–6

Hose (union nut) direct connection 4

Slave cylinder (bleeder screw) 4

Brake pad retainer at brake calliper 3–5

Cable clamp at brake calliper 4–6

1

si.shimano.com

2

sram.com

3

tektro.com

4

trpbrakes.com

5

magura.com

These values are reference values of the above-mentioned component manufacturers. Observe the values in the

instructions of the component manufacturers.

These values do not apply to the components of other manufacturers.

Loading...

Loading...