24 GS 461

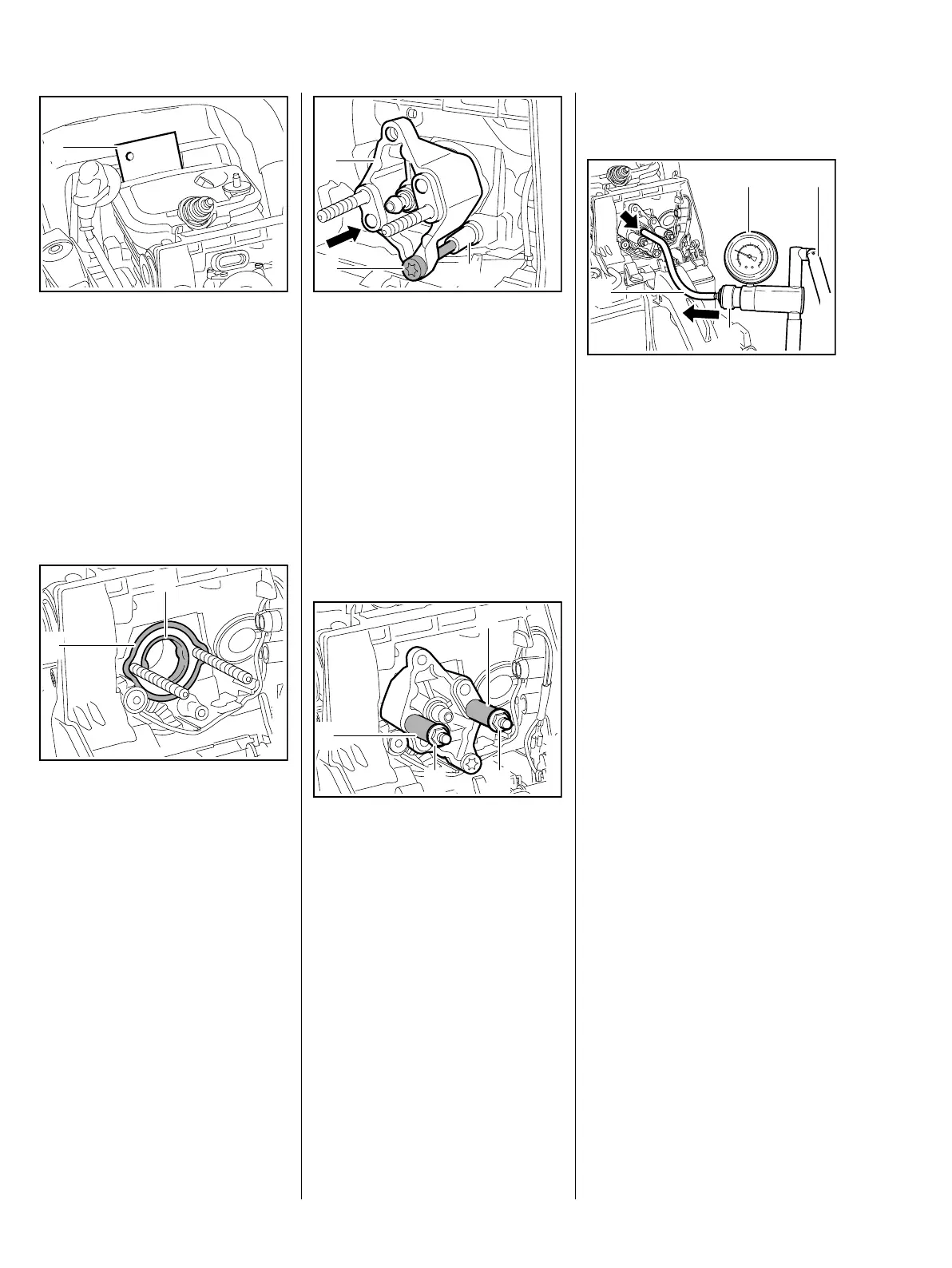

: Slide sealing plate (1)

0000 855 8106 on the cylinder

exhaust port between the cooling

plate and cylinder

– Tighten screws lightly

The sealing plate must fill the full

width between the screws.

– Remove the carburetor, b 10.3

: Washer (1) and sleeve (2) must

be fitted

3443RA063 TG

1

3443RA064 TG

1

2

: Orient flange (1) 5910 850 4200

and push it onto the studs

– Screw (2) for impulse hose

must be screwed in at the bottom

– Coat screw or inside of impulse

hose with STIHL press fluid,

b 12

: Slide on flange (1)

5910 850 4200 so that the

screw (2) engages in the impulse

hose (3)

: Slide on sleeves (1)

5910 893 1701

: Tightly screw on nuts (2)

3

1

3443RA065 TG

2

1

2411RA033 TG

1

2 2

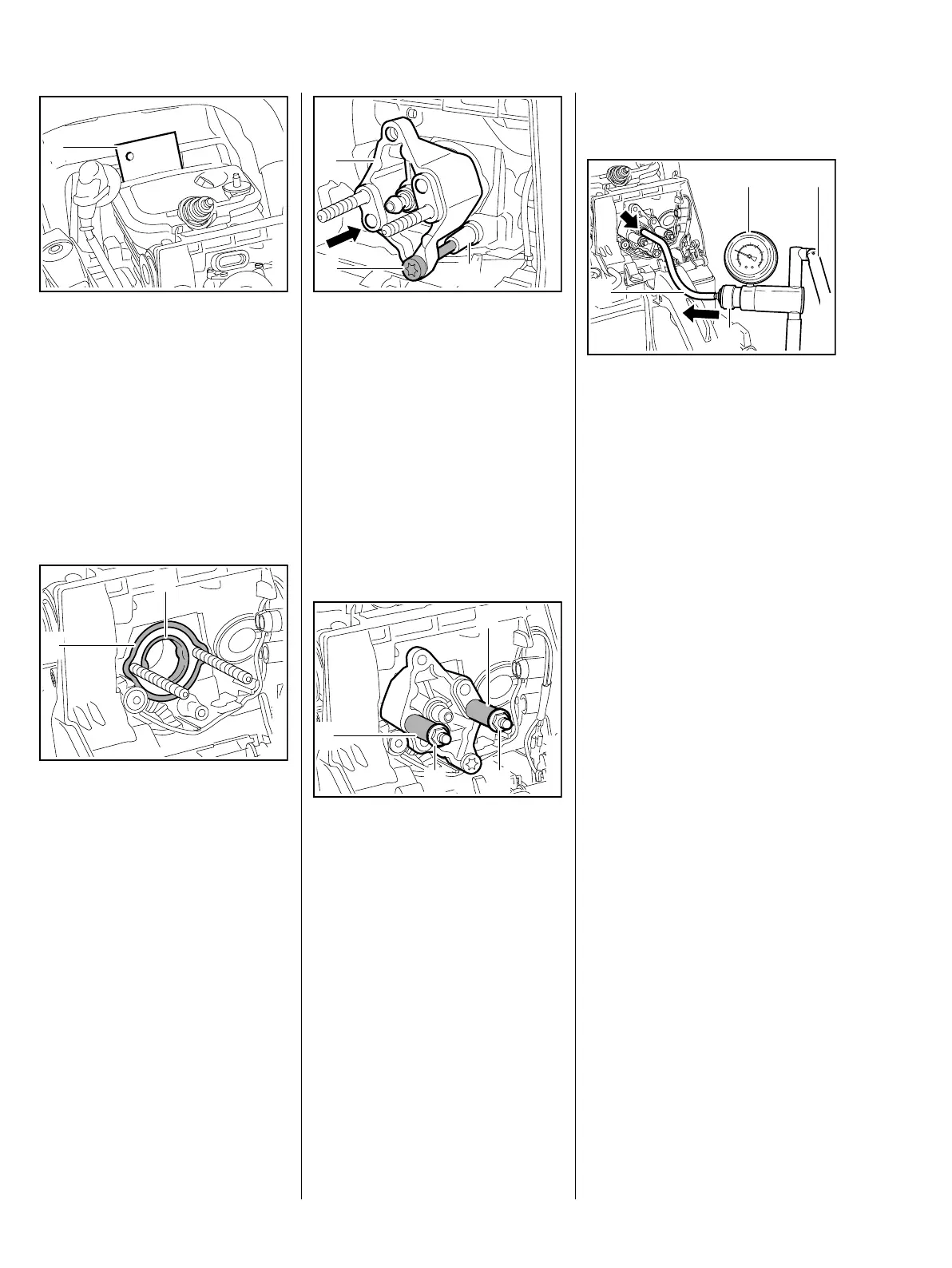

5.2.2 Testing with negative

pressure

: Push the hose (1) of pump

0000 850 1300 onto the

connector (arrow)

: Slide ring (2) to the left

– Vacuum test

: Operate lever (3) until the

pressure gauge (4) indicates a

vacuum of 0.5 bar

If the vacuum reading remains

constant, or does not decrease by

more than 0.3 bar within 20

seconds, it may be assumed that

the oil seals are in good condition.

If the vacuum in the crankcase is

reduced further,

the oil seals

must be replaced, b 5.3.

– After testing, slide the ring on the

pump back to the right to vent the

pump

– Continue with pressure test,

b 5.2.3

1

2411RA034 TG

2

4 3

Loading...

Loading...