40 GS 461

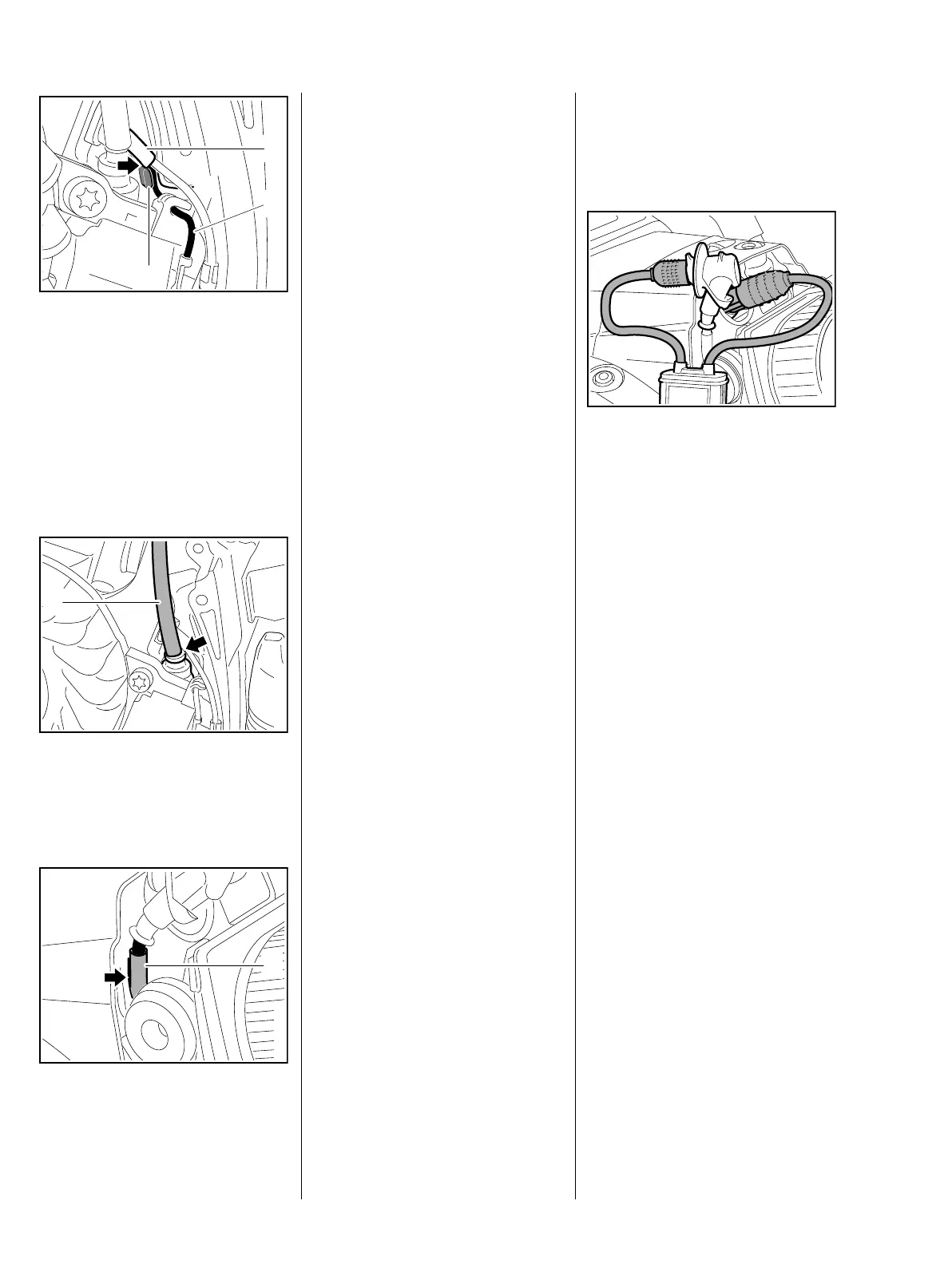

The compensation for longitudinal

movement of the short-circuit

wire (1) is between the crankcase

and the cable holder of the ignition

module

: Press short-circuit wire (1) into

the guide (2) – the protective

tube (3) must be flush with the fin

(arrow)

: Position insulating tube (1) so

that it

rests against the grommet

(arrow)

Protective tube (1) with ignition lead

must be in the guide (arrow) when

the shroud is fitted.

– Fit the shroud, b 5.4

3443RA202 TG

1

2

3

2411RA051 TG

1

3443RA194 TG

1

– Reassemble remaining parts in

reverse order

6.3 Testing the ignition

module

Before starting the test, install a new

spark plug.

The engine may start and

accelerate during the test.

– Test the ignition module using

either the ZAT 4 ignition system

tester 5910 850 4503 or the

ZAT 3 ignition system tester

5910 850 4520.

If a spark is visible, the ignition

system is in order.

– If no spark is visible in the spark

window, check the ignition

system with the aid of the

troubleshooting chart, b 6.7

The ignition test refers only to a

spark test, not to the ignition timing.

6.3.1 Testing the ignition

module with engine

analyzer MDG 1

The STIHL MDG 1 is used to easily,

reliably and quickly test the ignition

module.

The following is tested during the

test run:

– Ignition voltage

–Spark

– Short circuit

– Remove filter cover and air baffle

– secure air filter with slotted nut

– Before starting the test, check

spark plug, replace if necessary –

use only spark plugs

recommended by STIHL

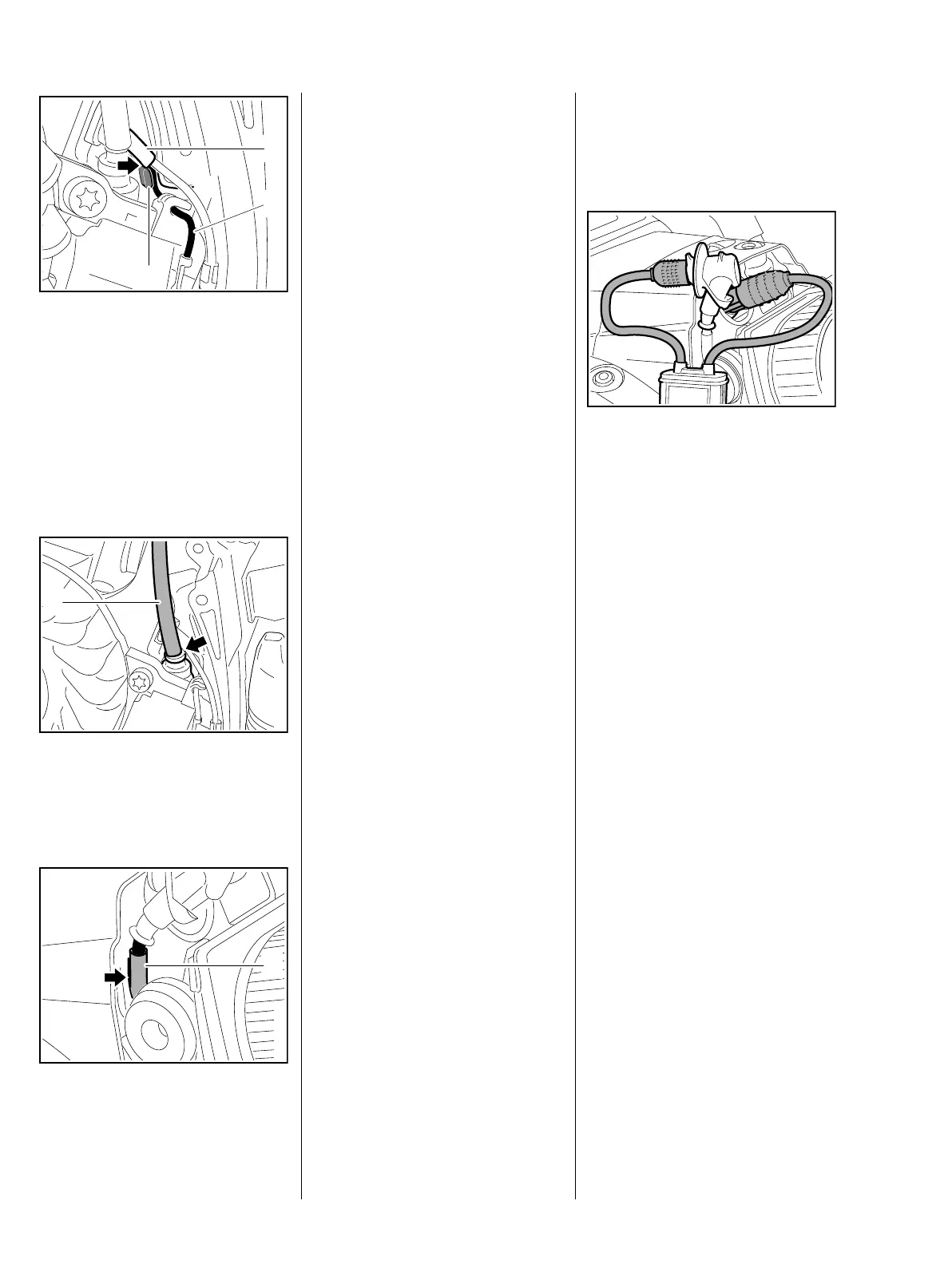

: Install engine analyzer MDG 1

between spark plug and spark

plug boot

– Ground clips must rest against

the hexagon of the spark plug

– To diagnose the GS 461, select

"Other STIHL products". Then

start the "Diagnosis" function and

follow the steps of the diagnostic

software.

For an accurate result, crank the

engine quickly with the rewind

starter.

The engine may start and

accelerate during the test.

3443RA205 TG

Loading...

Loading...