39GS 461

– Before twisting in the ignition

lead, fill the high-voltage output

with STIHL multi-purpose

grease, b 12

Do not use either graphite grease or

silicone insulating paste.

– Screw the ignition lead into the

ignition module – protective tube

and grommet must be pressed

onto ignition lead

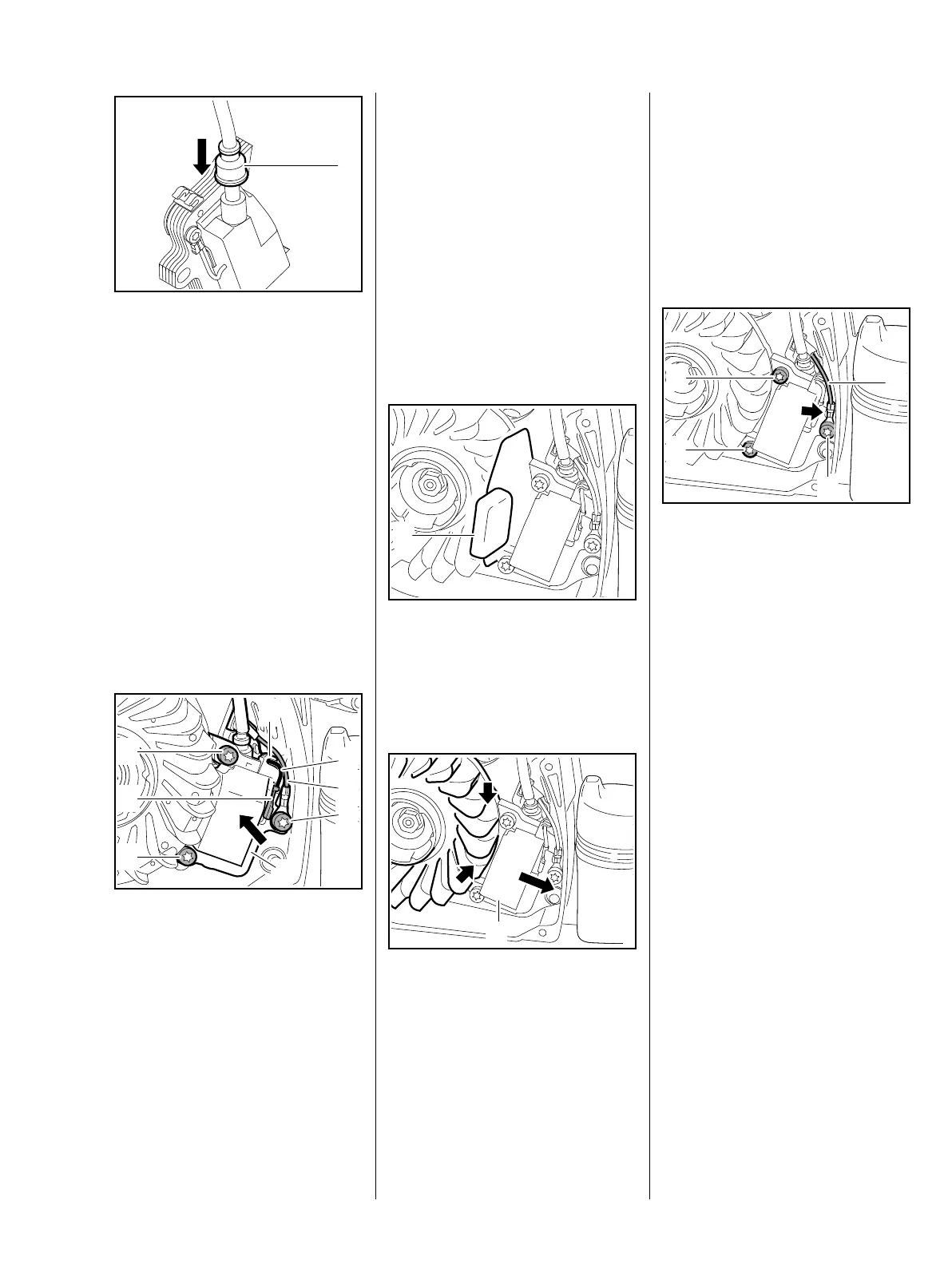

: Push on the grommet (1)

Grommet (1) must be pushed on

fully to avoid faults on the ignition

system caused by dirt or moisture.

The short circuit wire and ground

wire are run below the ignition lead

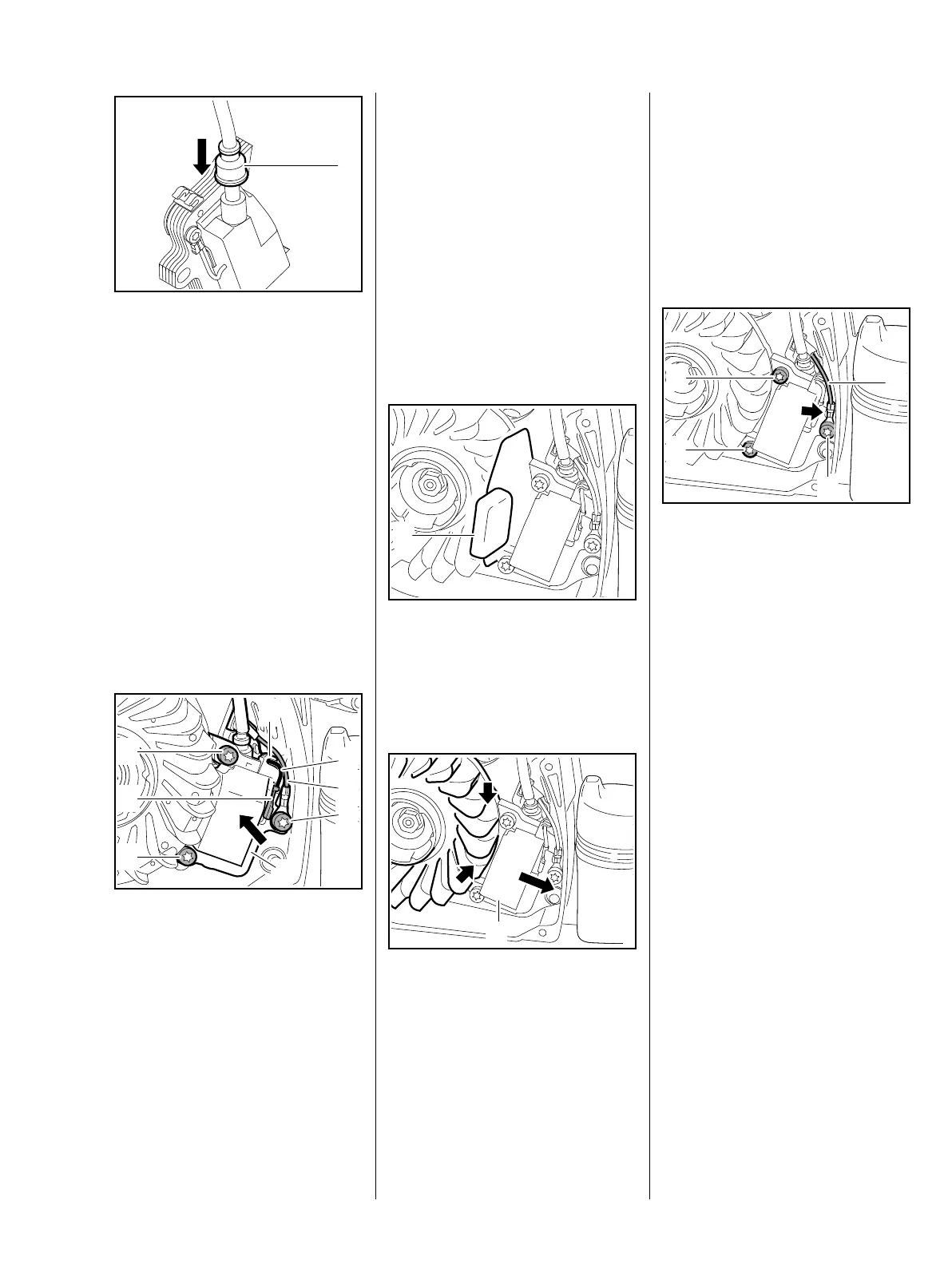

: Position ignition module (1) and

insert screws (2)

– do not tighten

3443RA186 TG

1

2411RA056 TG

3

4

1

7

2

2

6

5

: Position ground wire (3) and

insert screw (4)

– do not tighten

: Fit connector (5) of short-circuit

wire (6) with the crimped side

facing the ground wire

: Press short-circuit wire (6) into

the cable holder (7) so that there

is no tensile load

– Connector tab and blade

receptacle must run parallel to

the edge of the ignition module

: Push back ignition module and

slide setting gauge (1)

1111 890 6400 between the legs

of the ignition module and the

magnetic pole of the flywheel

Shown without setting gauge for a

better view.

: Push back ignition module (1)

and hold in place – flywheel must

turn freely

2411RA057 TG

1

N

S

2411RA058 TG

1

: Turn the flywheel until the raised

part of the magnet poles (arrows)

is on the ignition module

– Setting gauge is pressed in

during the process

: Press and hold the ignition

module (1) against the setting

gauge

: Tighten screws (1) and pull out

setting gauge

: Align cable lug (arrow) of the

ground wire (2) so that the

distance to the blade receptacle

and housing wall is the same,

hold in place and tighten

screw (3)

– Check correct functioning

– Turn the flywheel: it must not

touch the ignition module

N

S

2411RA059 TG

2

3

1

1

Loading...

Loading...