34 GS 461

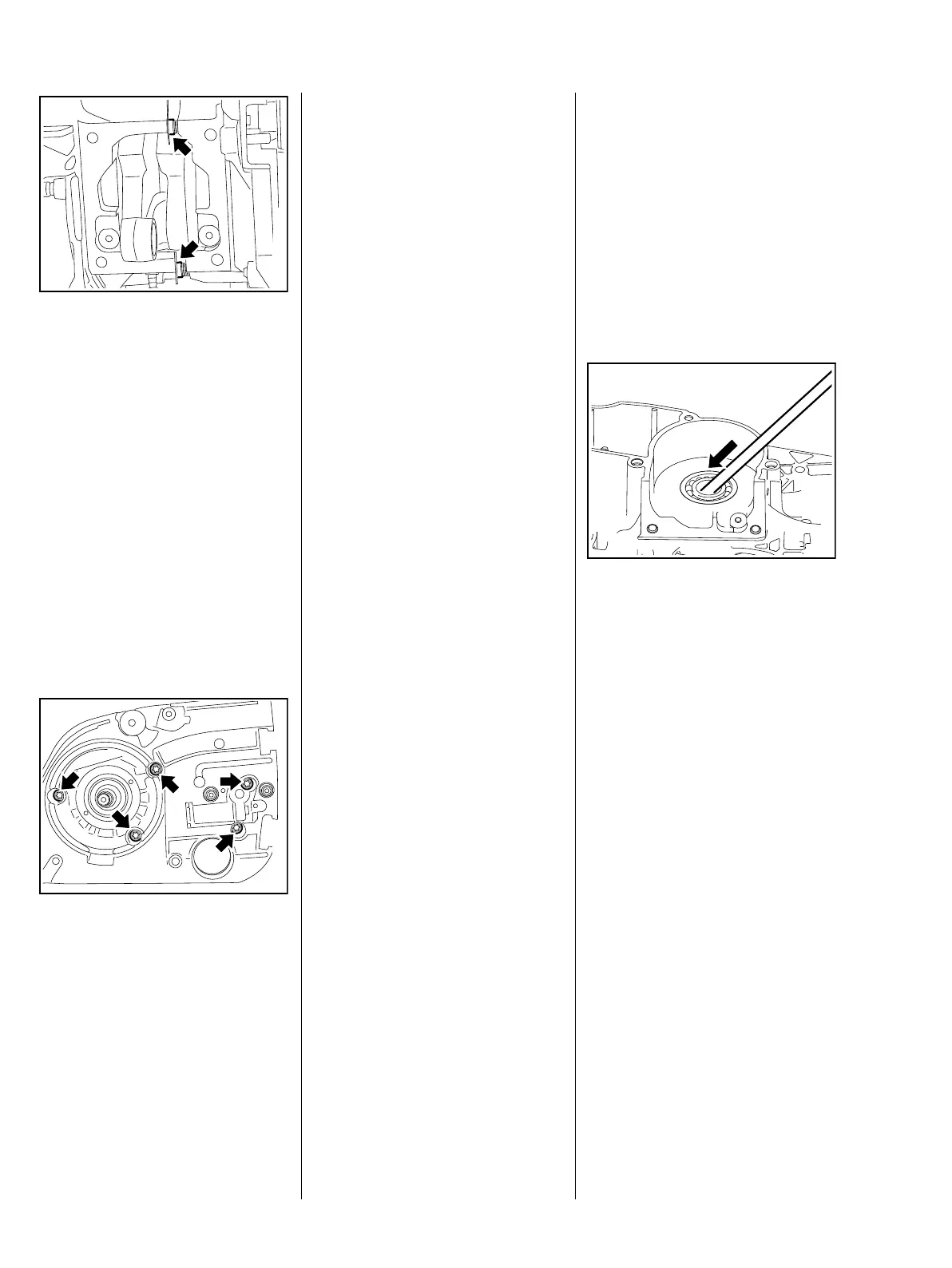

Ensure that the guide sleeves

(arrows) align with the holes and

that the housing gasket is not

jammed or buckled.

– Continue turning the spindle of

the assembly tool until the gap

between the halves of the

crankcase is closed

– Unscrew nuts.

– Turn the spindle clockwise to

remove the assembly tool

– Remove the two M5x72 screws

which were fitted to prevent

twisting

: Insert the screws (arrows) and

tighten them crosswise

– Install oil seals, b 5.3

– Fit flange with new oil seal,

b 5.3.1

3443RA117 TG

2411RA046 TG

– Examine and install the piston,

b 5.7

– Examine and install the cylinder,

b 5.5

– Reassemble remaining parts in

reverse order

5.6.1 Ball bearing / crankcase

The two halves of the crankcase

can be replaced individually if they

are defective.

Examine and clean the mating

surfaces of the crankcase halves

(including the cylinder sealing

surface) – The mating surfaces

must be without any damage

whatsoever.

New crankcase halves are

delivered with the relevant

components pre-assembled

– see spare parts list.

Those parts which are not supplied

with the new crankcase must be

removed from the old crankcase

halves, examined and replaced if

necessary.

When fitting a new crankcase, the

machine's serial number must be

stamped on the crankcase with 2.5

mm figure stamps.

If the old crankcase is reused, the

oil seals and ball bearings must be

replaced, all gasket residues

removed and the mating surfaces

cleaned thoroughly. The mating

surfaces must be absolutely

flawless and clean to guarantee a

perfect seal.

Examine both halves of the

crankcase for cracks and check all

mating surfaces for signs of

damage.

– Refer also to troubleshooting,

b 3.7

– Remove crankshaft, b 5.6

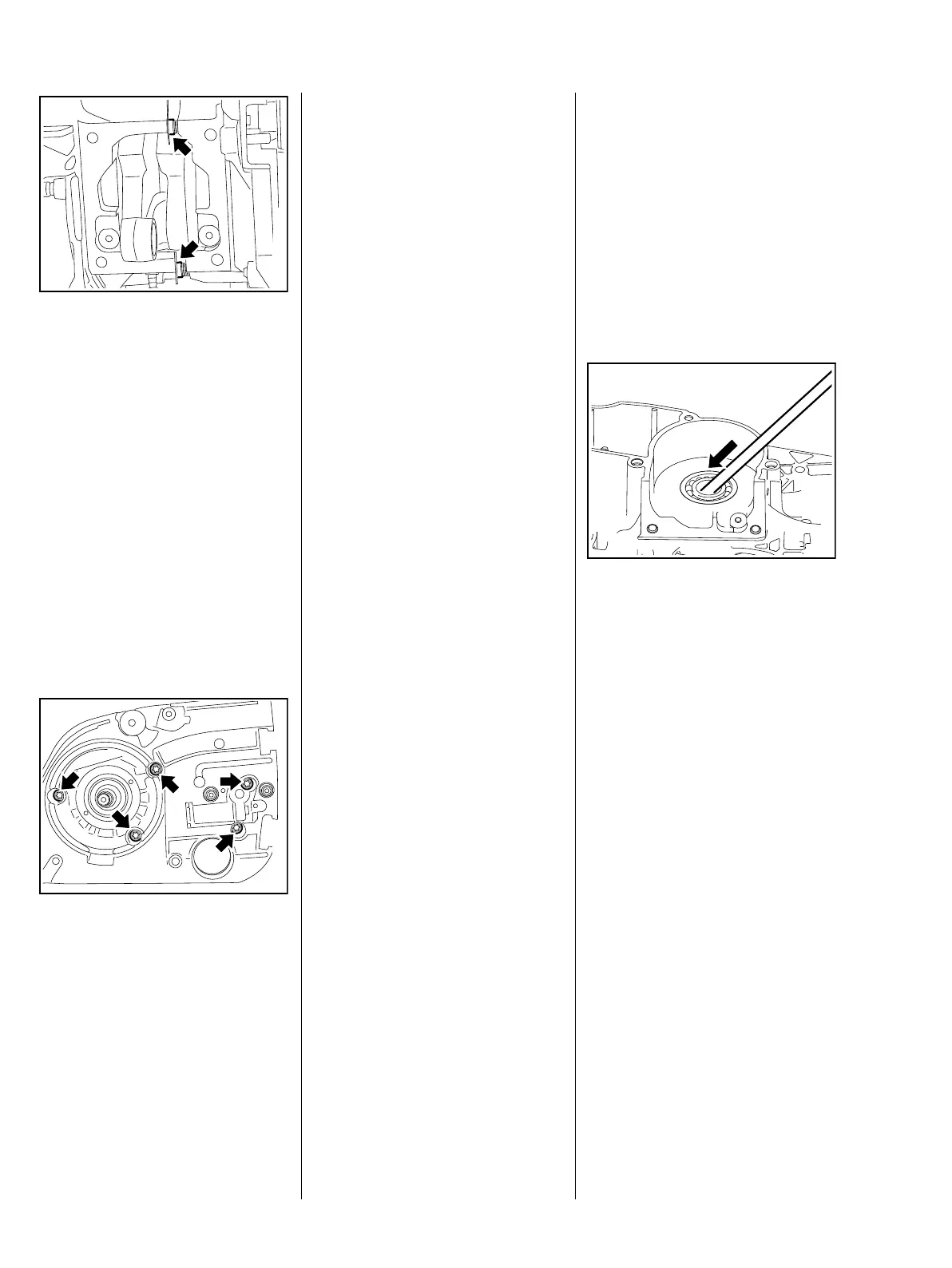

Ignition-side half of the

crankcase

: Carefully drive the oil seal out

with a punch

: Examine and clean the

crankcase half, replace if

necessary

– Replace the ball bearings if the

crankcase half is in good

condition.

– Heat the area around the bearing

seat to

approx. 160 °C (320 °F)

The bearing drops out of its own

accord when this temperature is

reached.

3443RA122 TG

Loading...

Loading...