10 Manual BBB4_ENG_01_2016_991301

Installation onto Driven Shaft

Taper-GripBushing

Taper-GripBushingIntroduction

The keyless Taper-Grip bushing system provides a simple and reliable shaft attachment

for Sumitomo speed reducers and gearmotors. This system allows bi-directional shaft

rotationoperationwithapowerful,slip-freegrip.Toassurepeakperformanceofyour

equipment,pleaseread,understandandfollowtheseinstallationinstructions.

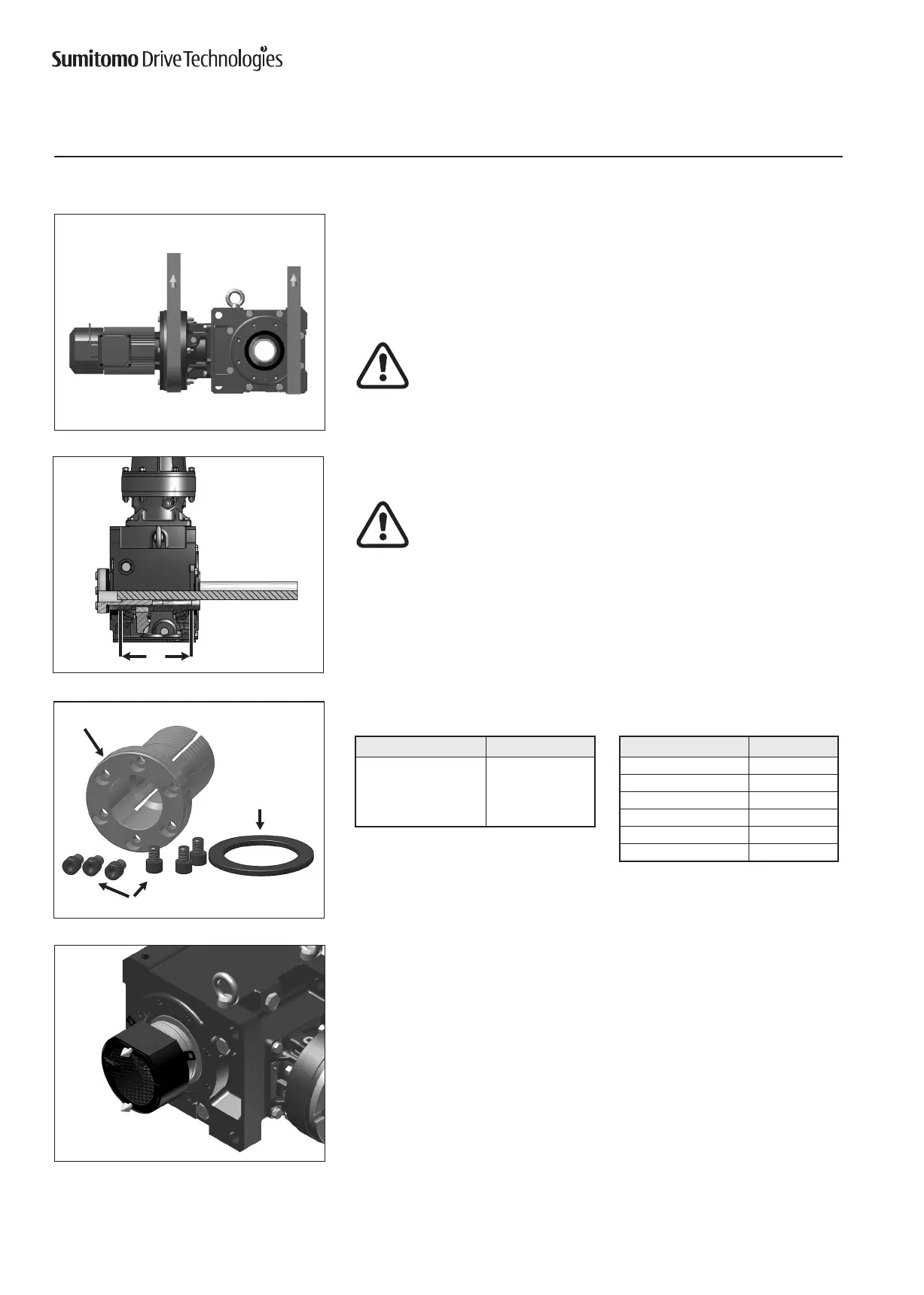

PriortoinstallationoftheBBB4ontothedrivenshaft,ensurethatthe

shaft length meets or exceeds the minimum shaft engagement value

“TT” detailed in Table 1.

Do not operate unit until the torque arm has been attached to the unit

and fixed to a rigid structure. The torque arm prevents counter-rotation

during unit operation. Refer to torque arm installation section in this

manual for instructions.

CAUTION: The BBB4 must be externally supported prior to insertion of

driven shaft into bushing. External support MUST be maintained until all

bushing socket head cap screws have been tightened to the appropriate

operational torque.

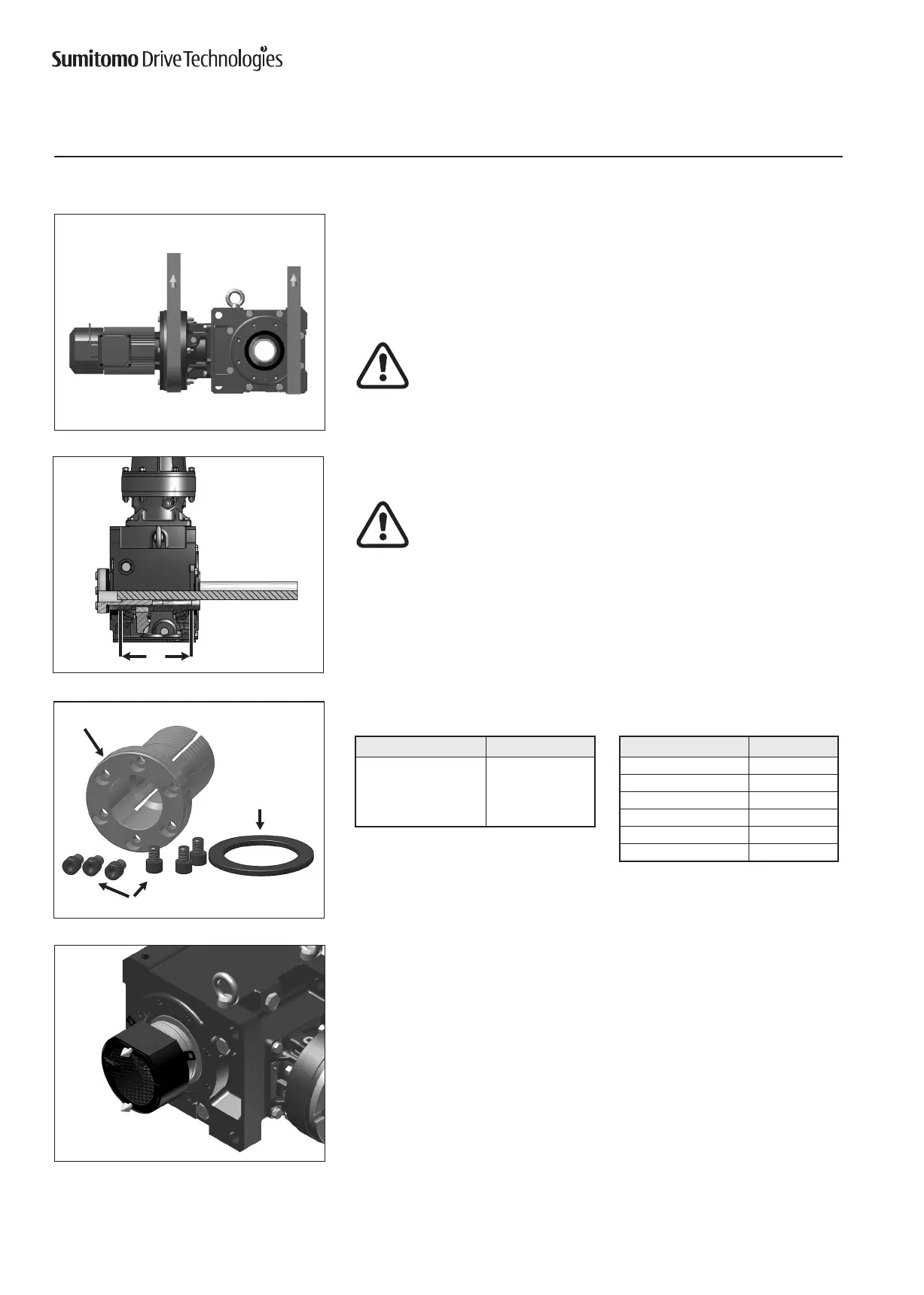

ComponentsofTaper-GripBushing

Asshowninthegureontheleft,theTaper-Gripbushingincludesthebushing,

thrust collar,andsocket head cap screws.

Table 1. Driven Shaft Tolerance

[1]

andMinimumShaftEngagement(TT)

Taper-GripBushingInstallationontoDriven

Shaft

1

Remove bushingcover if unit was supplied with one.

Taper-GripBushing

Socket Head Cap Screws

Thrust Collar

TT

BBB4 Size TT mm

4A 208

4B 242

4C 279

4D 326

4E 359

4F 412

Shaft Diameter mm Tolerance μm

30 - 50 +0 / -39

50 - 80 +0 / -46

80 - 120 +0 / -54

120 - 180 +0 / -63

Note: [1] Based on ISO/JIS/DIN h8

Loading...

Loading...