18 Manual BBB4_ENG_01_2016_991301

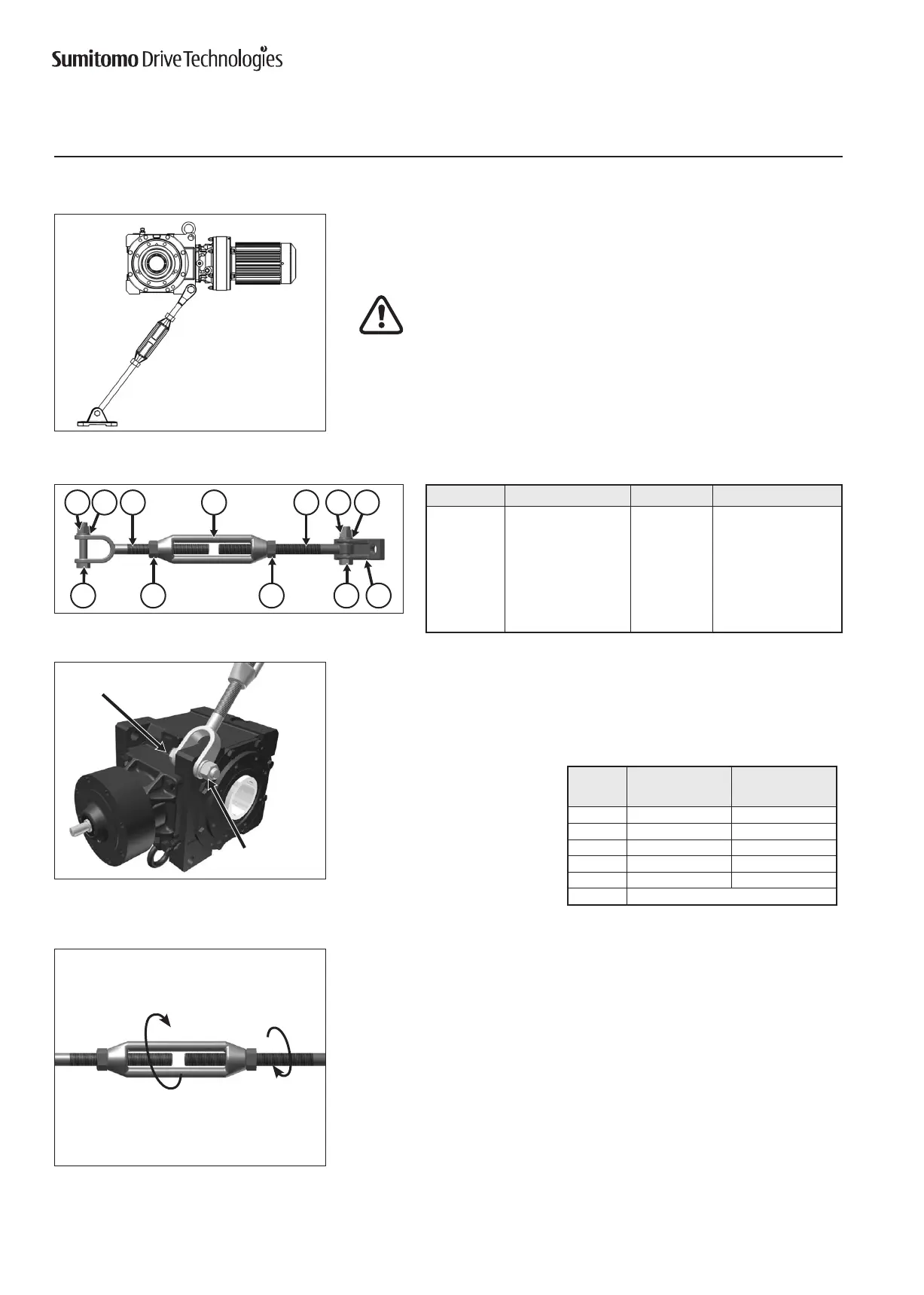

Torque Arm Introduction

A torque arm is a device used to prevent counter-rotation of the shaft mounted

reducer/gearmotor during operation.

The torque arm must be mounted in tension when torque arm

mounting point is greater than 6 inches (150mm) from machine mount-

ingpointor,tie-rodorturnbuckletypetorquearmisused.

Torque Arm Installation

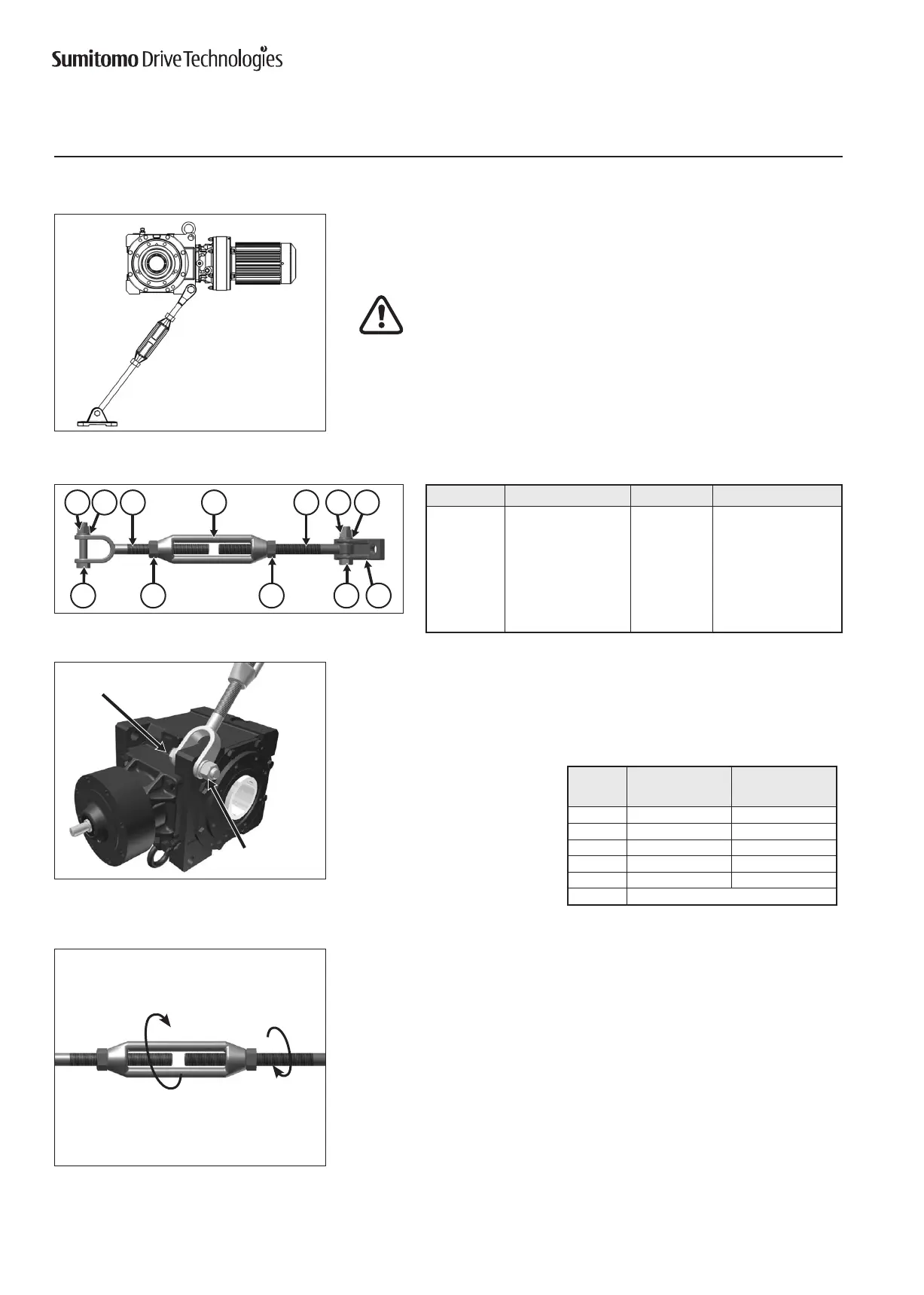

Torque Arm Introduction, Turnbuckle Type Torque Arm

1

Attachthetorquearmthreadedextensionrodtothebevelhousing,asshown

intheFigure,atthehousingcornereyelet,usingtheappropriatenut,boltand

lockwasher.

•Inserttheboltthroughthe

brackets,torquearmsleeve(if

supplied) and reducer housing

eyelet.

•Placethelockwasheronthebolt

and secure with nut.

2

Install the turnbuckle onto the threaded extension rod (gearbox side) and then

threaded arm (foundation side) to the turnbuckle

Iftheassemblywassuppliedwithhexnutstosecuretheturnbuckle,installthe

nutsloosely,ensuringthelefthandnutisusedonthethreadedarm,priorto

installing the turnbuckle and threaded arm

Unit

Size

Bolt Size

[1]

N•m

A M16 x 75 206 – 227

B M20 x 100 392 – 431

C M24 x 105 686 – 755

D M24 x 125 686 – 755

E M24 x 125 686 – 755

F Consult Factory

Table6.BoltTighteningTorques

Note: [1] Bolt Class equal to ISO/JIS Class 8.8

Turnbuckle Type Torque Arm Parts

Item Number Description Item Number Description

1 Hex Nut 7 Locke Washer

2 Lock Washer 8

Fulcrum Mounting Bracket

3 Threaded Extension Rod 9 Hex Bolt

4 Turnbuckle 10 Locking Nut (if supplied)

5 Threaded Arm 11 Locking Nut (if supplied

6 Hex Bolt 12 Hex Bolt

Table 5. Turnbuckle Type Torque Arm Parts

Insert Bolt

TightenNut

1 2 3 4 5 6 7

12 91011 8

Turnbuckle Rod Type Torque Arm Parts

Loading...

Loading...