Manual BBB4_ENG_01_2016_991301 25

1. Introduction

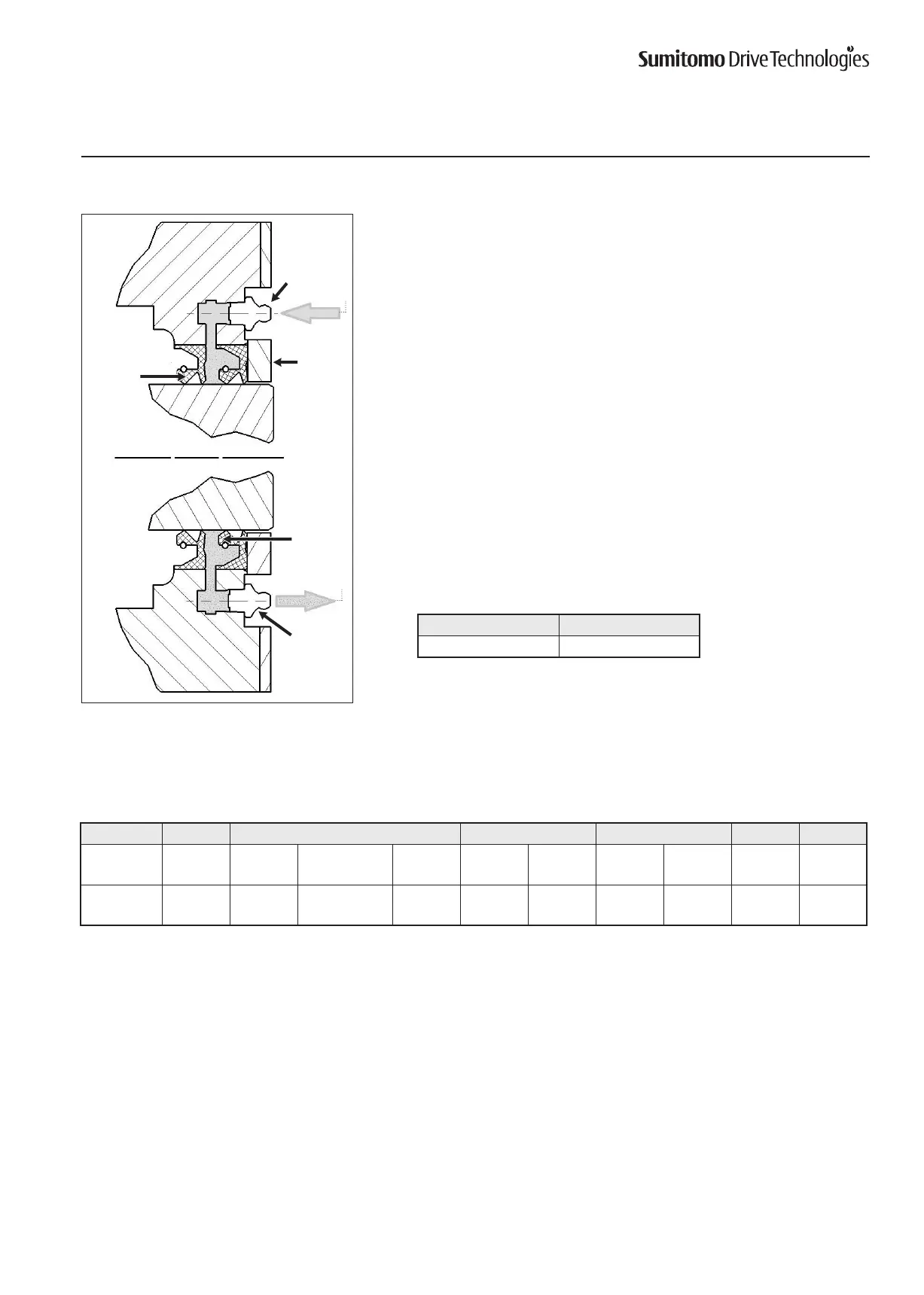

Taconite seals may be used in high dust operating environments. They use a grease

purging system to prevent outside contaminants from entering the speed reducer/

gearmotor. Figure to the left details the Taconite Seal assembly as utilized in the

4-Series Bevel Buddybox .

2. Procedure

PleasefollowtheseinstructionstomaintainlubricationoftheTaconiteSealsystem:

a. Unlessotherwisespecied,theTaconiteoutputsealsareeach

packed with NLGI #2 EP mineral grease prior to unit shipment

from the factory location.

b. Grease does not need to be added to the seals prior to unit

start-up.

c. Add grease to the seals according to the guidelines indicated in

Table 13. Refer to Table 14 for recommended greases.

Please note that a highly contaminated environment may require

a more frequent lubrication cycle.

Grease Nipple

Grease In

Seal Plate

Oil Seal

(greaseretainer)

Oil Seal

(greaseretainer)

Grease Out

GreasePurge

Fitting

Taconite Seal Assembly

Output Shaft RPM Hours of Operation

>200 5,000

Table 13. Lubrication Cycle

Grease BP Castrol Chevron/Texaco Exxon/Mobil Shell Total

Mineral

Ener-Grease

LS EP2

Spheerol

AP3

Olista Longtime

3EP

Tribol 3020/

1000-2

Duralith

Grease EP2

Multifak

Grease EP2

Beacon

EP2

Mobilux

EP2

Alvania

EP2

Multis

EP2

Food

Grade

FM EP2

Table 14. Recommended NLGI#2 Mineral Greases

Lubrication

Taconite Seal Lubrication Procedure

Loading...

Loading...