14 Manual BBB4_ENG_01_2016_991301

Installation onto Driven Shaft, continued

Keyed Hollow Bore

Keyed Hollow Bore Installation

Do not operate unit until the torque arm has been attached to the unit and fixed to a rigid structure. The torque arm prevents

counter-rotation during unit operation. Refer to torque arm Installation section in this manual for instructions.

CAUTION: The BBB4 must be externally supported prior to insertion of driven shaft into hollow bore.

Bore and Shaft Tolerance Specifications

•Unlessotherwisespecied,thetoleranceoftheHollowShaftBoretoleranceH8.

•Ifapplicationinvolveshighshockloadingand/orlargeradialloads,ashafttoleranceofjs6ork6isrecommended.

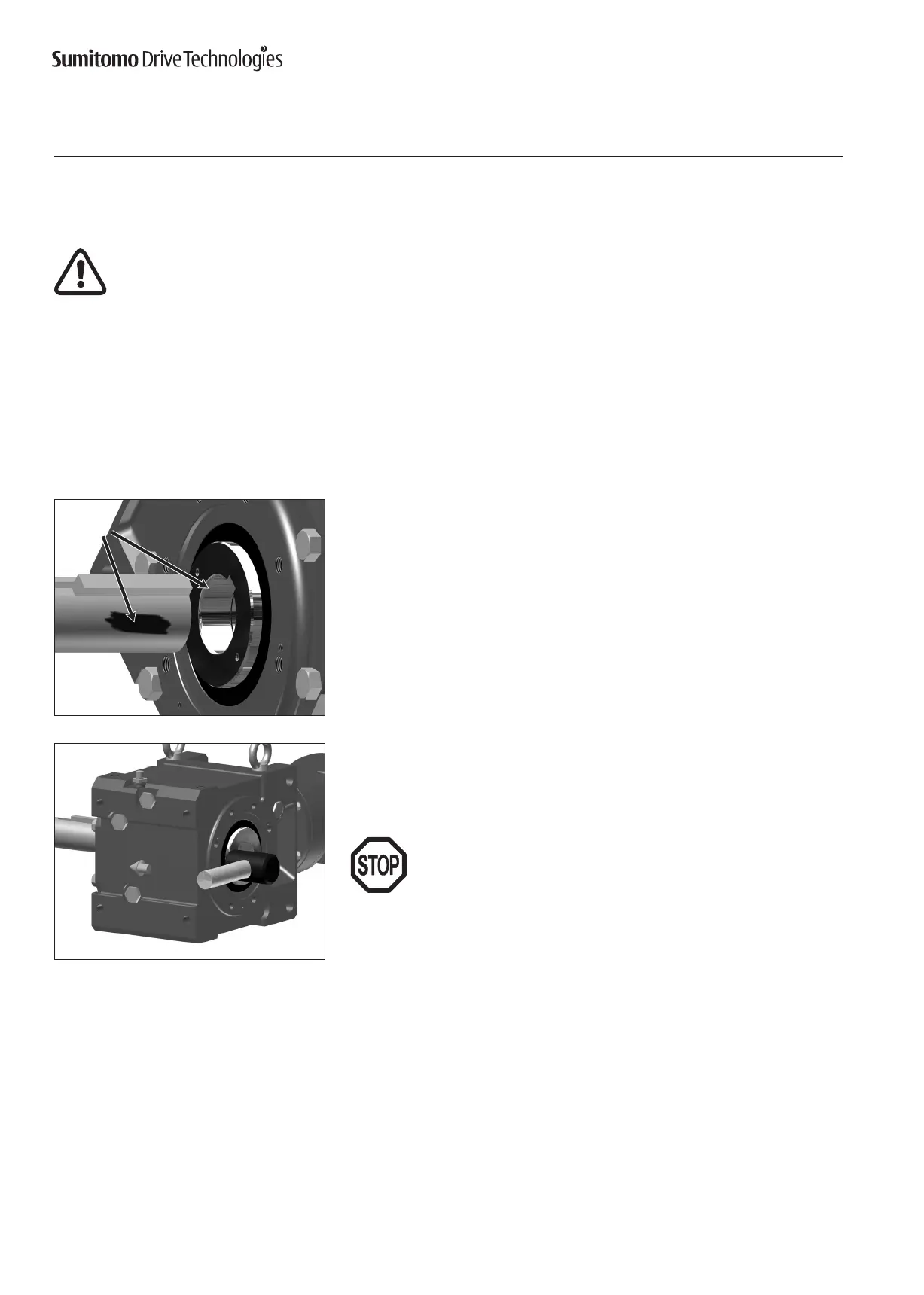

Anti-sieze

compound

Keyed Hollow Bore Installation

onto Driven Shaft

1

Apply anti seize compound to the driven shaft surface and inside the reducer keyed

hollow bore.

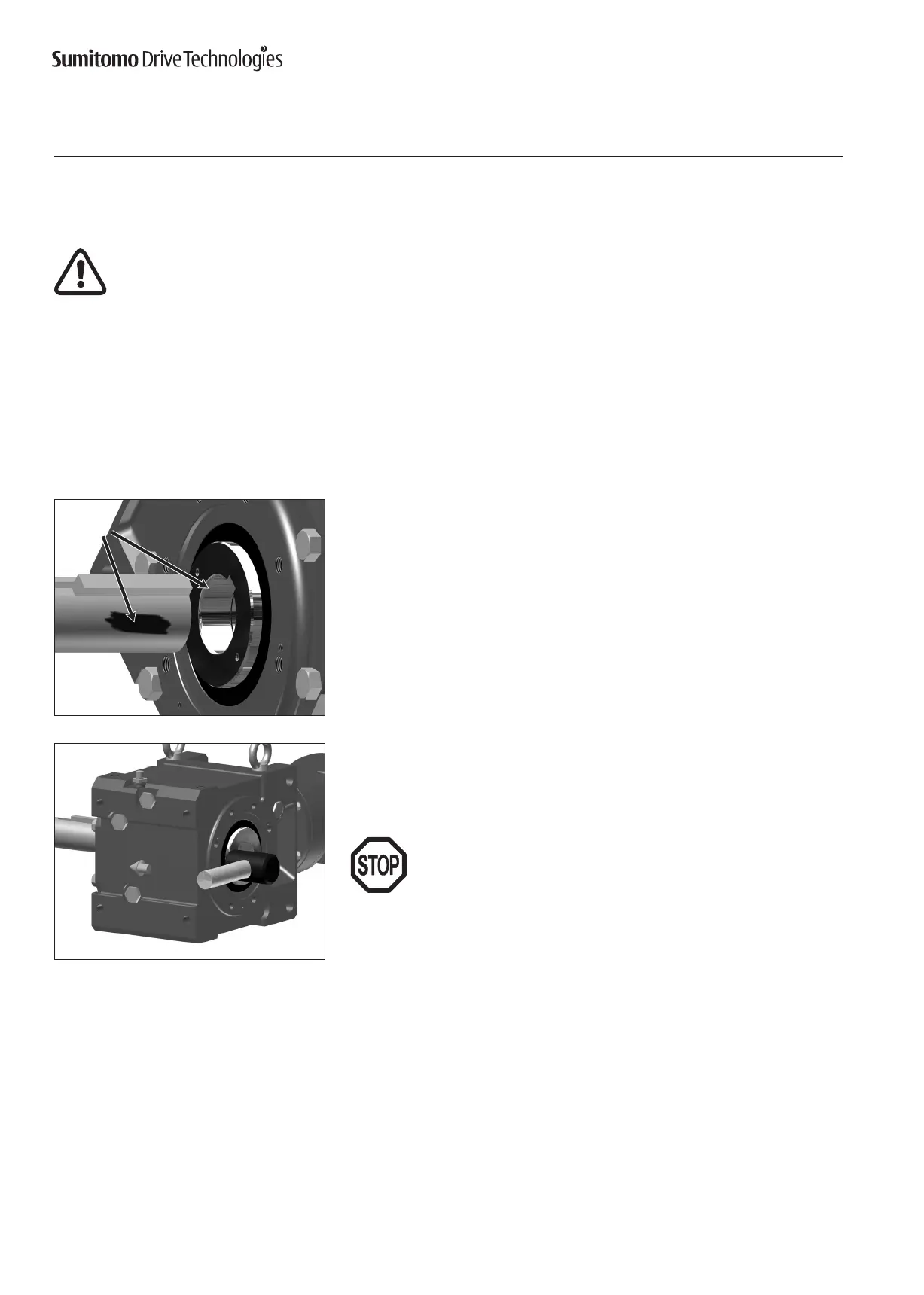

2

Align the driven shaft with the reducer/gearmotor bore and carefully slide unit onto

the driven shaft to the desired location.

Ifthetistight,strikeonthekeyedhollowborewithawoodenorhard

rubber mallet to assist in the assembly.

Ifusingamalletduringinstallation,strikeonly against the unit’s steel

keyed hollow bore. Do not strike the reducer housing or oil seal as

damagetothebearings,housingand/orsealsmayoccur.

Note:Ifthetistight,useajigsuchastheoneshowninTable3toease

assembly. Sumitomodoesnotsupplyamountingjig.Thisinforma-

tion is provided for reference only.

Loading...

Loading...