16 Manual BBB4_ENG_01_2016_991301

Size

Model

(Typical)

Bolt

Bolt Torque

N•m

4A TAS-3071-55x68

10 x M6x25

ISO/JIS grade 10.9

12

4B TAS-3081-65x80

7 x M8x30

ISO/JIS grade 12.9

34

4C TAS-3081-75x100

12 x M8x35

ISO/JIS grade 12.9

34

4D TAS-3093-85x110

12 x M10x45

ISO/JIS grade 12.9

68

4E TAS-3081-100x140

10 x M12x45

ISO/JIS grade 12.9

118

4F TAS-3071-120x165

8 x M16x55

ISO/JIS grade 12.9

290

Table4.ShrinkDiscBoltTighteningTorques

2

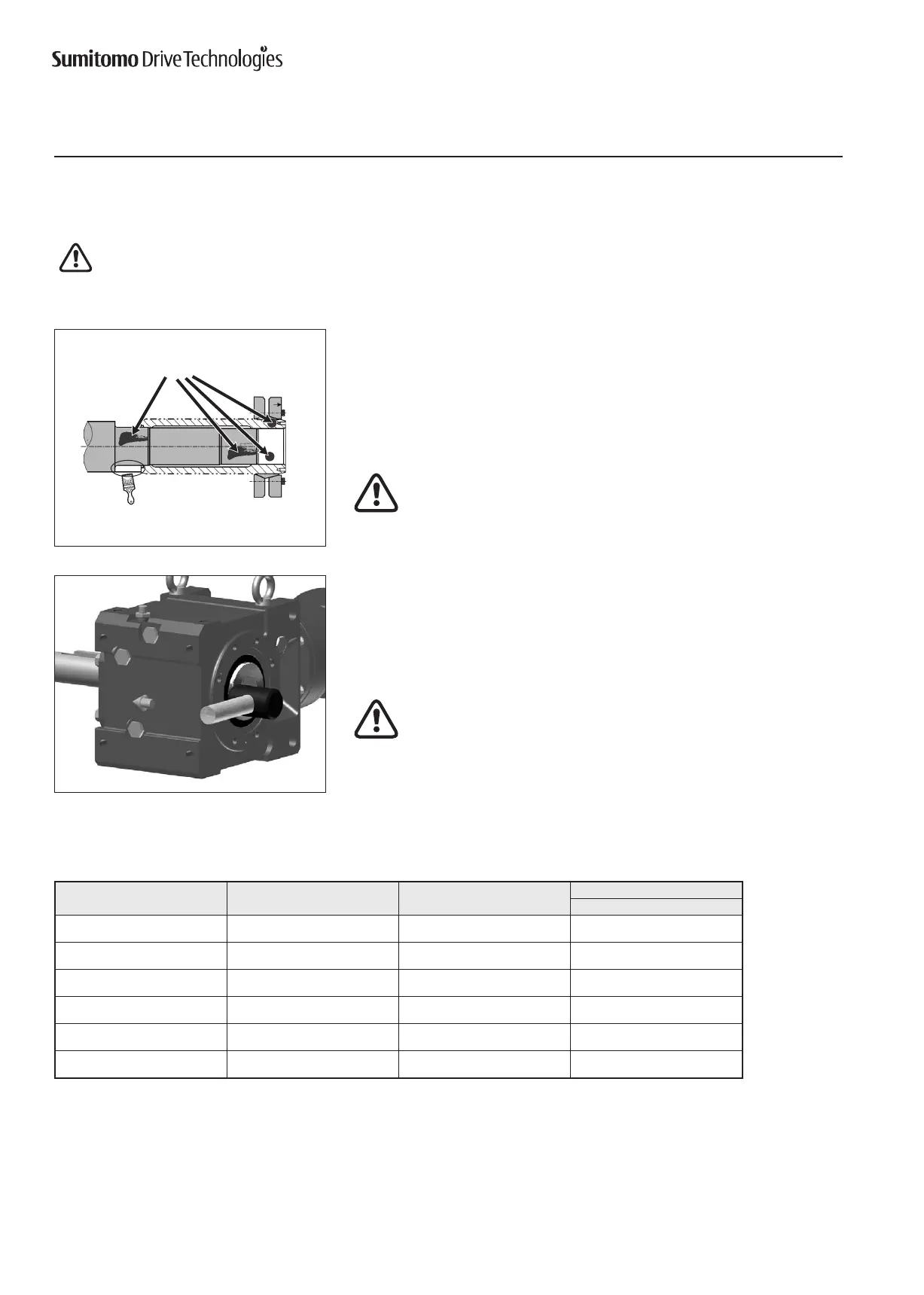

Align the driven shaft with the bore of reducer/gearmotor bore and carefully slide

unit onto the driven shaft to the desired location.

•Ifthetistight,strikeonthereducerhollowborewithamallettoassistintheassembly.

Ifusingamalletduringinstallation,strikeonly against the unit’s steel

hollow bore. Do notstrikethereducerhousingoroilseal,asdamageto

thebearings,housing,and/orsealsmayoccur.

Ifthetistight,useajigsuchastheoneshownintheKeyedHollowBore

Installation section to ease assembly. Sumitomo does not supply a

mountingjig.Thisinformationisprovidedforreferenceonly.

Installation onto Driven Shaft, continued

Shrink Disc Type Hollow Bore

1

Cleananddegreasecontactsurfaces;reducershaftandbore,andthemachine

driven shaft.

Apply Molykote 321 or an equivalent dry film lubricant to the driven shaft shoulder

opposite from the shrink disc.

Do Not apply any friction minimizing compound to the driven shaft at or

near the shrink disc.

Degrease

these areas

Apply Molykote 321

to this shaft area only

Shrink Disc Type Hollow Bore Installation onto Shaft

Beforeplacingunitontodrivenshaft,donotapplygrease,oil,oranti-seizepastetotheentiredrivenshaftortothebore

of the shrink disc. Use of these friction-minimizing products will adversely affect the ability of the unit to transmit torque.

Never tighten locking screws before shaft installation. Inner ring may become permanently contracted even at low tightening

torques.

Loading...

Loading...