Manual BBB4_ENG_01_2016_991301 29

Lubrication, continued

Recommended Lubricants

Bevel Gear Portion and Cyclo Portion Lubricants

Recommended Oils

Table 17, Recommended Oils, lists the oils that may be used to lubricate the Bevel Gear portion of the unit. These oils may also be used

in the Cyclo portion if it is oil lubricated.

Table 17. Recommended Oils.

Manufacturer Type of oil Manufacturer Type of oil

AVIA Gear RSX MOBIL Mobilgear 600XP

CASTROL Alpha EP SHELL Omala

DEA Falcon CLP TOTAL Carter EP / XEP

KLÜBER Klüberoil GEM1

•Uselubricantswithlowviscosityforoperationduringwinteroratrelativelylowtemperatures.

•UsealubricantwithaviscositywithintherangelistedinTable 18, Recommended Oil Viscosity.

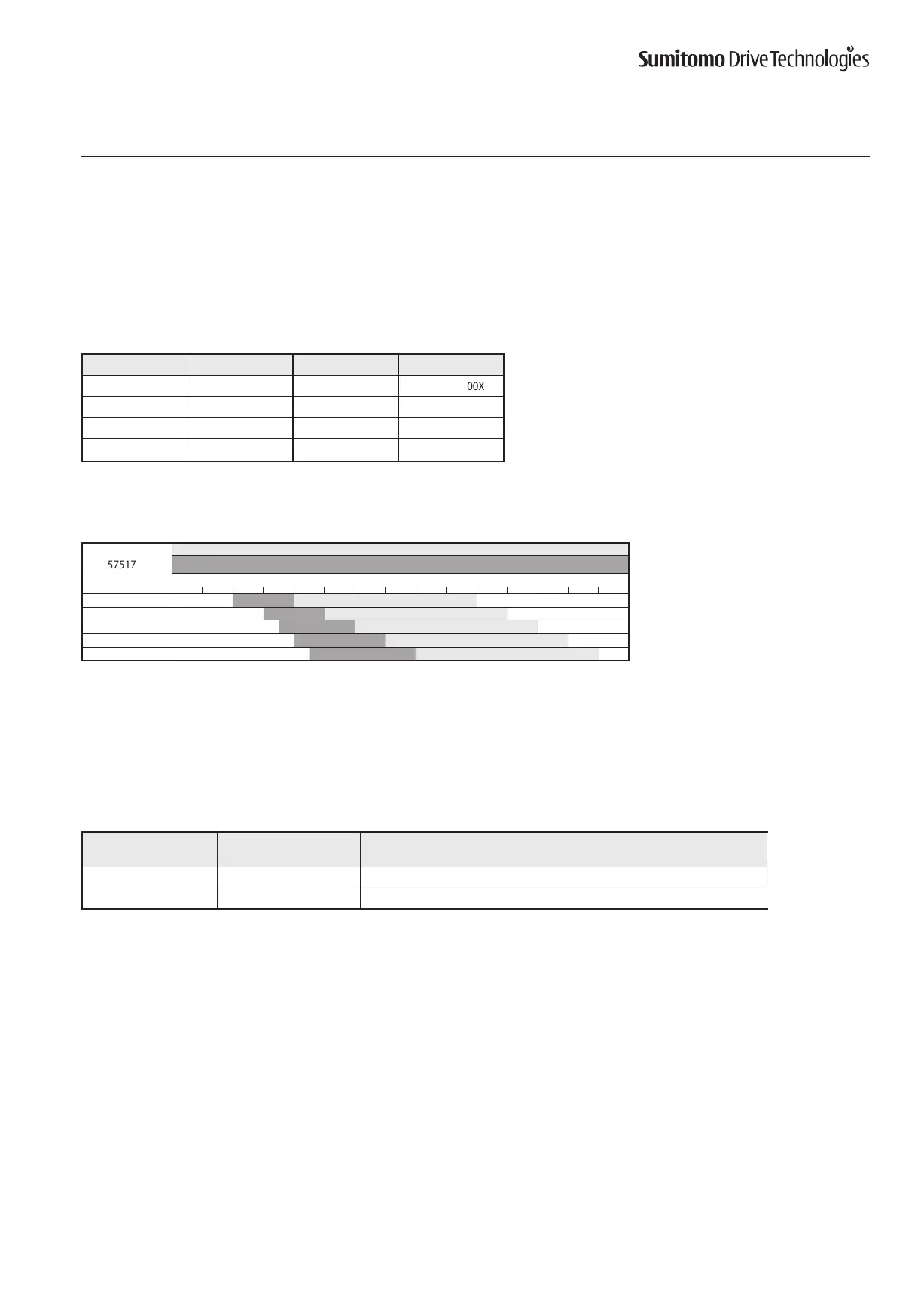

Table 18. Recommended Oil Viscosity

lubricant as per

DIN 57517 part 3

possible operating temperatures °C

ambient temperature °C

-20°C 0° +20° +40° +60° +80° +100°

CLP 68

CLP 100

CLP 150

CLP 220

CLP 320

•Consultlocaldistributor,nearestauthorizedagentorSumitomodirectlywhentheunitwillbeoperatedinambienttemperatures

other than -10° – 40°C. Special unit modifications may be necessary.

Cyclo Portion Approved Greases

Table 19, Cyclo Portion Approved Greases,liststhegreasesthatmaybeusedtolubricatetheCycloportionifgreaseisthespecied

lubrication method (refer to the Lubrication Method section for details).

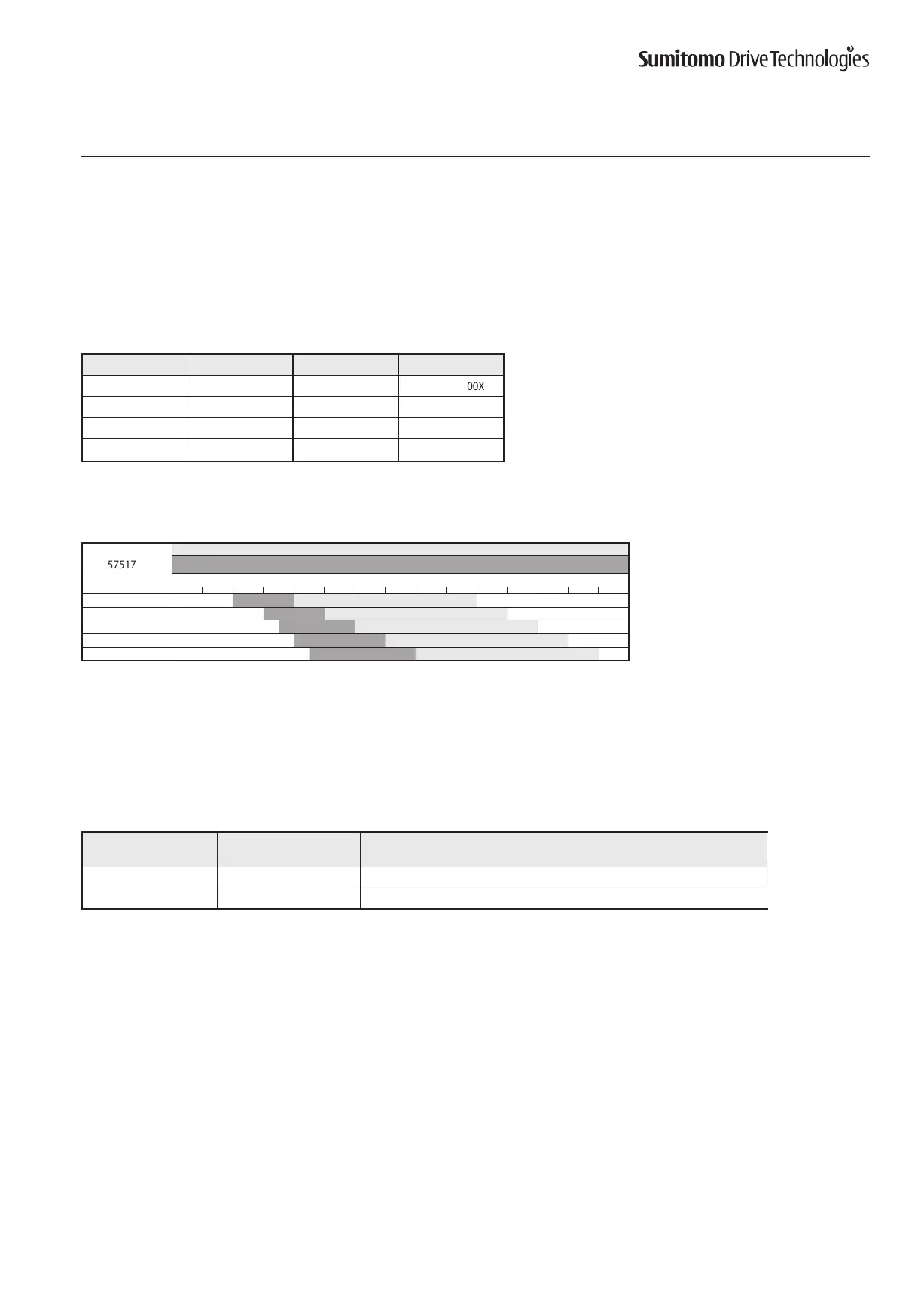

Table 19. Cyclo Portion Approved Greases

Ambient Temp.

°C

Overall

Reduction Ratio

All Unit Sizes

-10º – 50 ºC

11:1through18:1 Shell Gadus S2 V220 00

19:1andhigher Esso Unirex N2

Cyclo portions have unique operating characteristics that require specific lubricant properties. Please consult Sumitomo if alternate

lubricants are required.

Loading...

Loading...