Manual BBB4_ENG_01_2016_99130119

Torque Arm Installation, continued

Turnbuckle Type Torque Arm

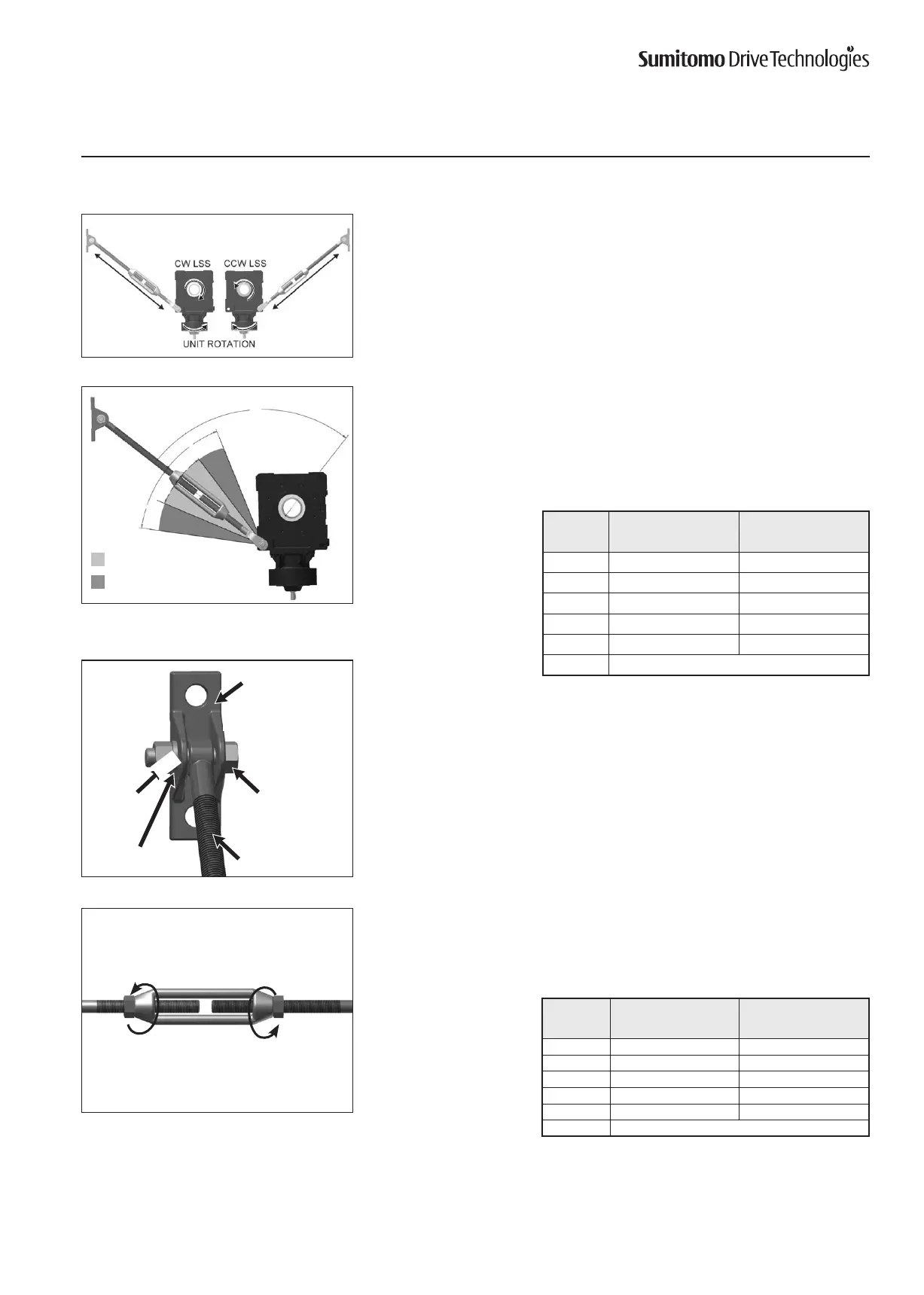

3

Position the torque arm so it will be in tension during unit operation and mount the

fulcrum mounting bracket to suitable structure or foundation. Consider installing

two torque arms for reversing applications to allow torque arm to be in tension for

each direction of rotation.

Mounting hardware for fulcrum mounting bracket are NOT supplied by Sumitomo.

4

Position the torque arm as close as possible to 90° relative to the unit output bore /

driven equipment shaft.

Sumitomo does not recommend combining torque arm assemblies to achieve a

greater overall length.

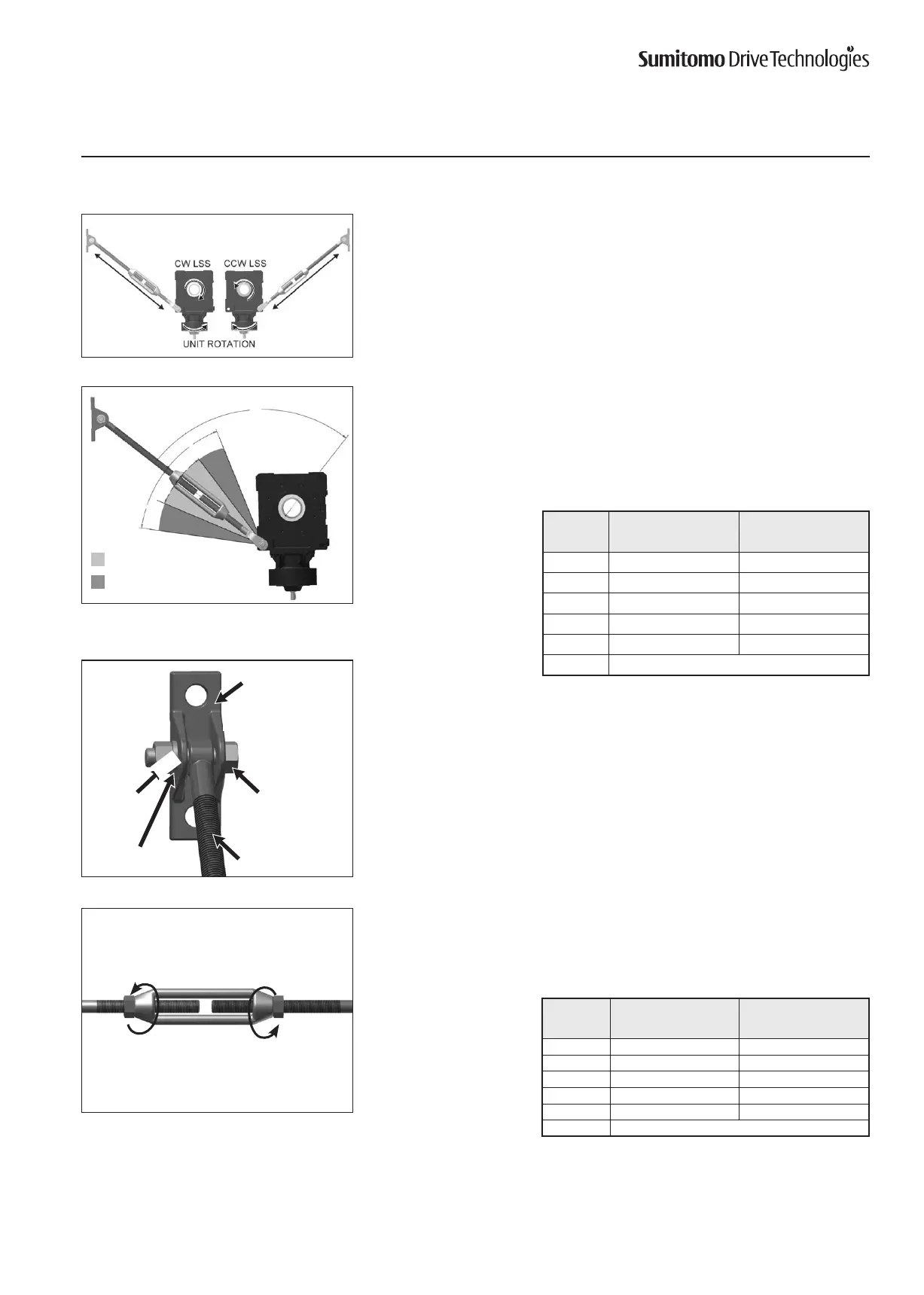

5

Assemble the threaded

armtothefulcrummountingbracket,asshown.

Someadjustmentoftheturnbucklemayberequiredtolengthenorshortenthe

overall length.

Secureitwiththeappropriatenut,boltandlockwasher.

•Inserttheboltthroughthebracketsandthreadedarmeyelet.

•Placethelockwasherontheboltandsecurewithnut.

6

Ifturnbucklehexnutsweresupplied,securetheturnbucklepositionbyadjusting

the previously installed turnbuckle nuts.

OPTIMUM MOUNTING

ACCEPTABLE MOUNTING

Threaded Arm

Bolt

Nut

Lock Washer

MountingBracket

Unit

Size

Bolt Size

[1]

N•m

A M16 x 65 206 – 227

B M16 x 80 206 – 227

C M16 x 80 206 – 227

D M16 x 80 206 – 227

E M16 x 80 206 – 227

F Consult Factory

Table7.BoltTighteningTorques

Note: [1] Bolt Class equal to ISO/JIS Class 8.8

90

30

30

15

15

Unit

Size

Nut Size

[1]

N•m

A M20 392 – 431

B M24 686 – 755

C M24 686 – 755

D M24 686 – 755

E M24 686 – 755

F Consult Factory

Table8.NutTighteningTorques

.

Loading...

Loading...