20 Manual BBB4_ENG_01_2016_991301

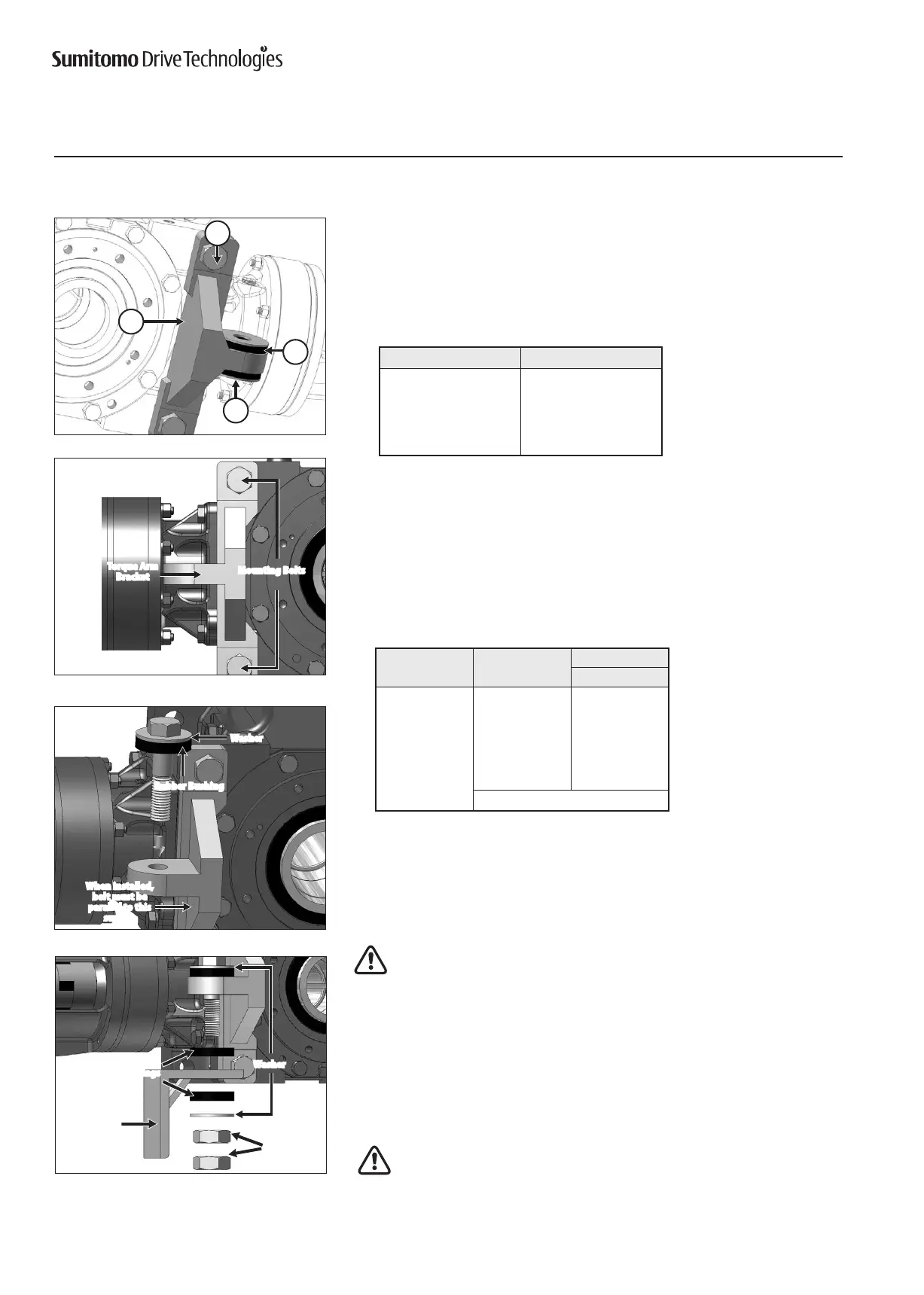

T-Type Torque Arm

Sumitomo Supplied Components for T-Type

Torque Arm

T-Type Torque Arm Installation Procedure

1

Attach the T-Type Torque Arm Bracket to the BBB4 using the supplied

mounting hardware.

TightenmountingboltsaccordingtothevalueslistedinTable10:

Table 10. T-Bracket Bolt Torques

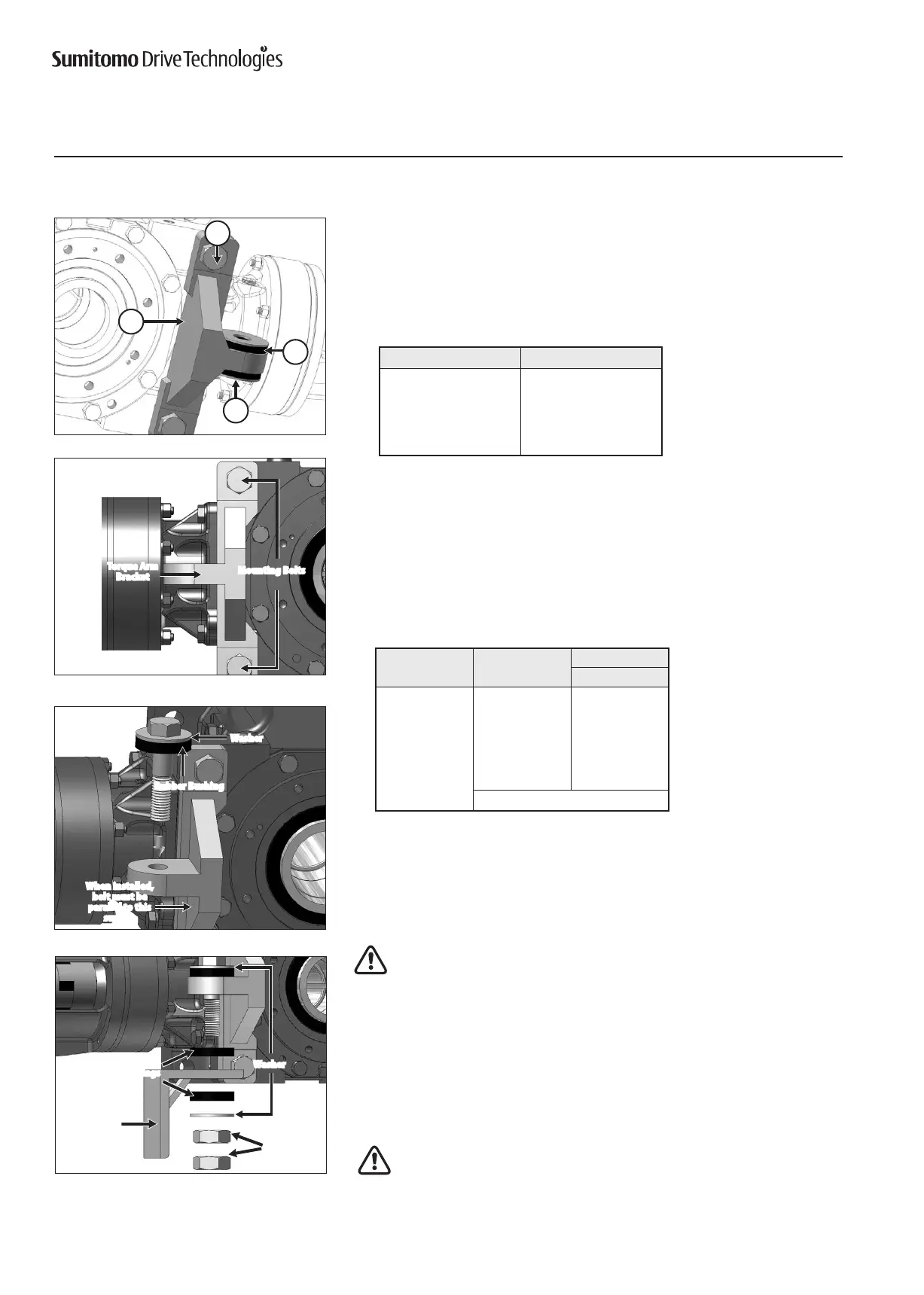

2

Place washer and rubber bushing on bolt.

Insert torque arm bolt (supplied by customer) through torque arm mounting tab.

T-Type bolt sizes listed in Table 11.

Make sure bolt is parallel to T-Type Torque Arm side when fully installed.

3

Followthesestepstoattachthemountinganglebracket:

• Placerubberbushingandmountinganglebracketonbolt.

• Verifythatthemountinganglebracketholeisthecorrectdiameterforcustomer

supplied bolt.

• Placeremainingbushing,washerandtwonutsonthebolt.

Donotover-tightennuts.Tightentopointwhererubberbushingscan

still be hand rotated.

Torque Arm Installation, continued

T-Type Torque Arm

1

2

3

4

Torque Arm

Bracket

MountingBolts

Washer

RubberBushing

When installed,

bolt must be

parallel to this

surface

Nuts

(CustomerSupplied)

RubberBushings

Washer

MountingAngle

Bracket

(Customer

Supplied)

Item Number Description

1 Torque Arm Bracket

2 Bracket Hardware

3 Rubber Bushing (qty 3)

4 Washer (qty 2)

BBB4 Size

Bracket

Bolt Size

[1]

Torque

N•m

4A 2 x M16 206 – 227

4B 2 x M20 392 – 431

4C 2 x M24 686 – 755

4D 2 x M30 1373 – 1510

4E

2 x M30 1373 – 1510

4F

T-Type Not Available

Table 9. T-Type Torque Arm Components

Note: [1] Bolt class equal to ISO/JIS Class 8.8

Loading...

Loading...