Manual BBB4_ENG_01_2016_991301 21

Torque Arm Installation, continued

T-Type Torque Arm

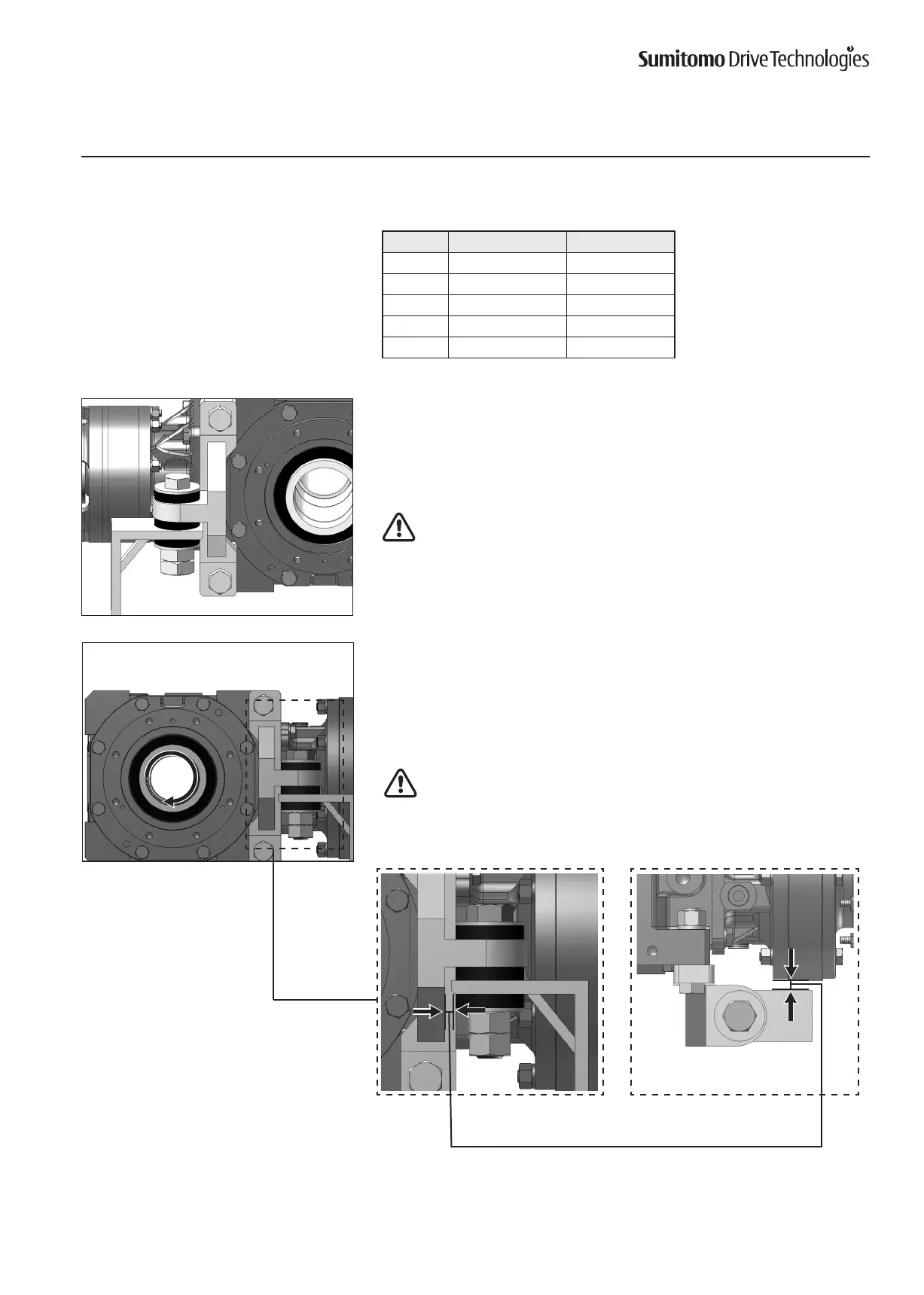

Top View

4

Confirm that the rubberbushingscan still be rotated by hand. This indicates the

bushing has not been over tightened.

Compressed bushings will not allow the bushings to properly absorb the

loads of the shaft mounted gearbox. This can lead to premature failure.

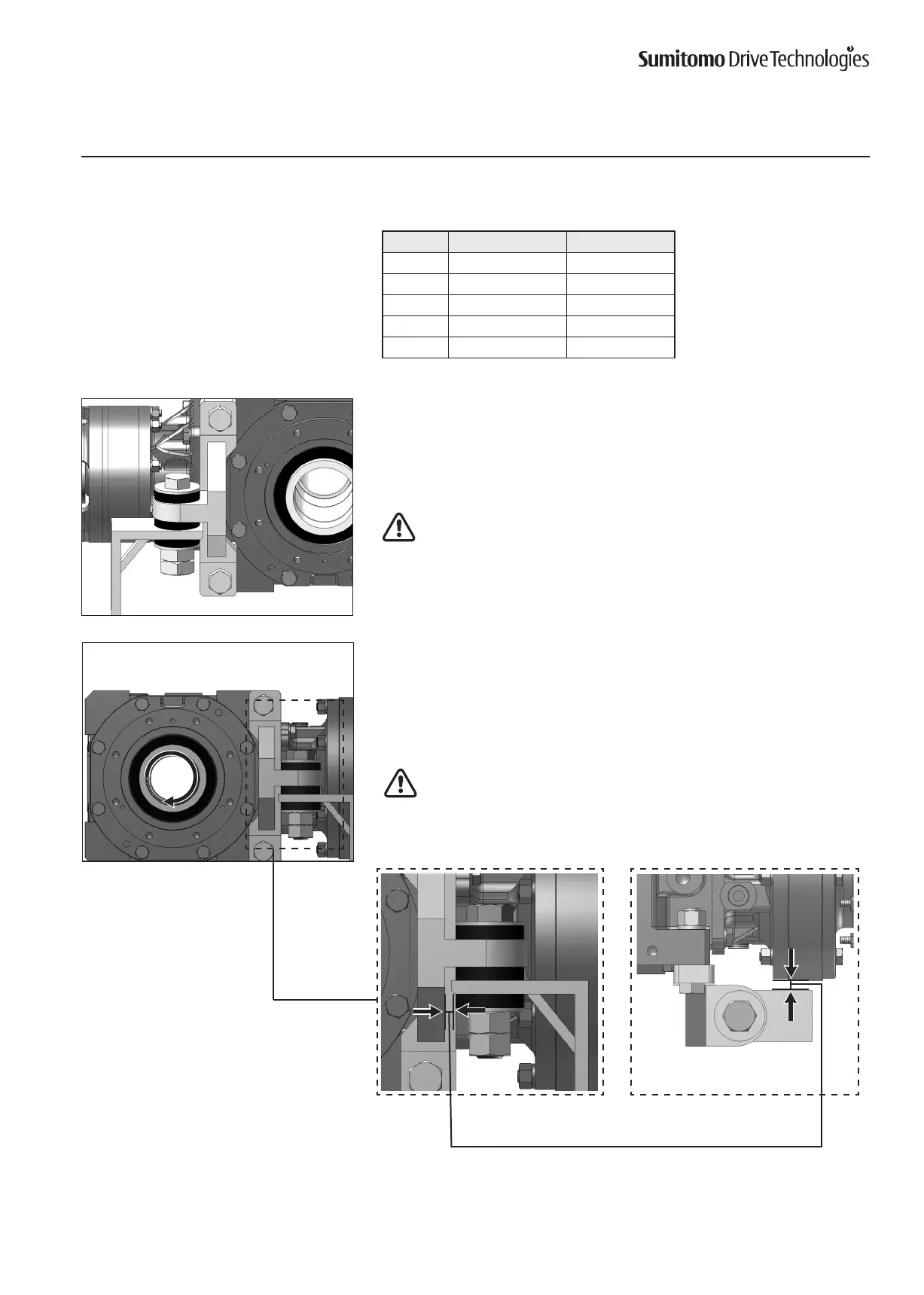

Mountinganglebracketmustbesecuredtothemachinestructure.

5

Conrmthemountinganglebracketdoesnotinterferewiththetorquearm.

There should be no metal-to-metal contact between the two during a complete

revolution of the driven equipment.

Metal-to-Metal contact between these two components may lead to

catastrophic failure of the reducer/ gearmotor.

Unit Size Bracket Tab Bore Typical Bolt Size

[1]

4A Ø18mm M16

4B Ø18mm M16

4C Ø22mm M20

4D Ø26mm M24

4E Ø33mm M30

Table 11. T-Type Bolt Dimensions

Note: [1] Bolt class should be greater or equal to ISO/JIS Class 8.8. Application with multiple start/stops and/or shock

loading should use ISO/JIS 10.9 at a minimum.

Loading...

Loading...