Manual BBB4_ENG_01_2016_991301 23

5

Place a soft-metal (i.e. brass) bar against the flange of the Taper-Grip bushing and

carefully strike end of bar with a hammer to release the bushing.

6

Apply a liquid penetrant to the shaft where it contacts the bushing. Allow time for

the liquid to settle between the shaft and the bushing wall. Once the penetrant has

settledadequately,carefullyremovetheBBB4fromthedrivenshaft.

If the Taper-Grip bushing releases but the unit cannot be removed from the driven

shaft,apullermayneedtobeappliedtothebushingangetopulltheunitfree

from the shaft.

Removal of BBB4 with Keyed Hollow Bore

Beforestartingunitremovalprocess,ensurethatelectricalpowertounithas

been safely locked out and that electrical connections to the unit have been

disconnected.

1

Remove safety cover and the shaft-retaining device from the driven shaft.

Removal from Driven Shaft, continued

Removal of BBB4 with Keyed Hollow Bore

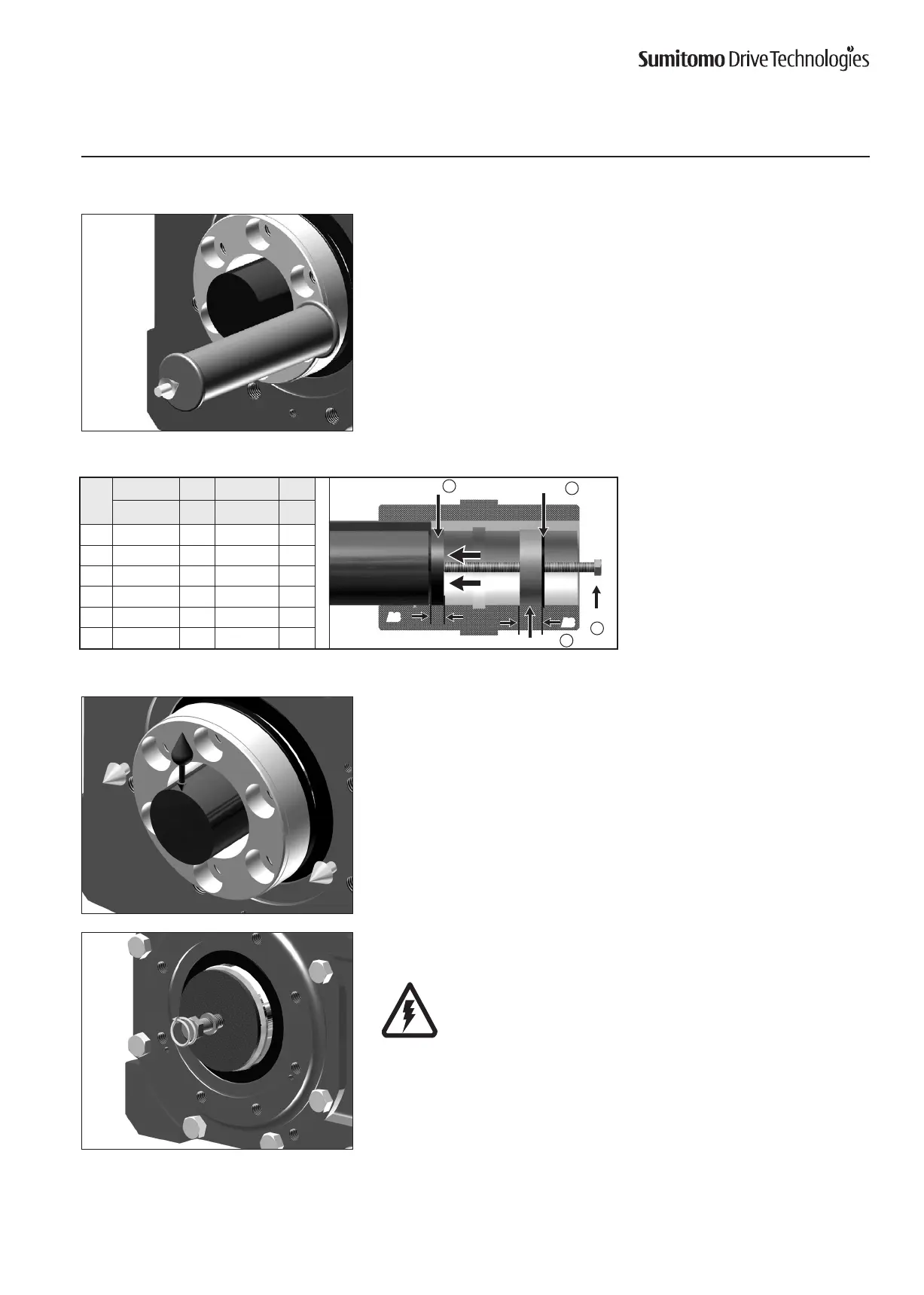

Size

a f g h

CC(ISO/JIS) A3 BOLT A8

4A

55 19 M24x250 6

4B

65 19 M24x300 6

4C

75 19 M24x300 5

4D

85 24 M30x400 5

4E

100 19 M30x400 5

4F

120 30 M36×450 7

Table12.RemovalJigDimensions

Ifshaftremovalisdicult,ajigsuchastheoneshowninTable12maybeusedtoeasethe

removal process. Sumitomodoesnotsupplytheremovaljig.

This information is supplied for reference only.

InternalSnapRinga

Spacer: Threaded f

Bolt

g

Thrust Disc h

A3

A8

Loading...

Loading...