Cyclo® HBB

Operation & Maintenance Manual 21

Cyclo® HBB

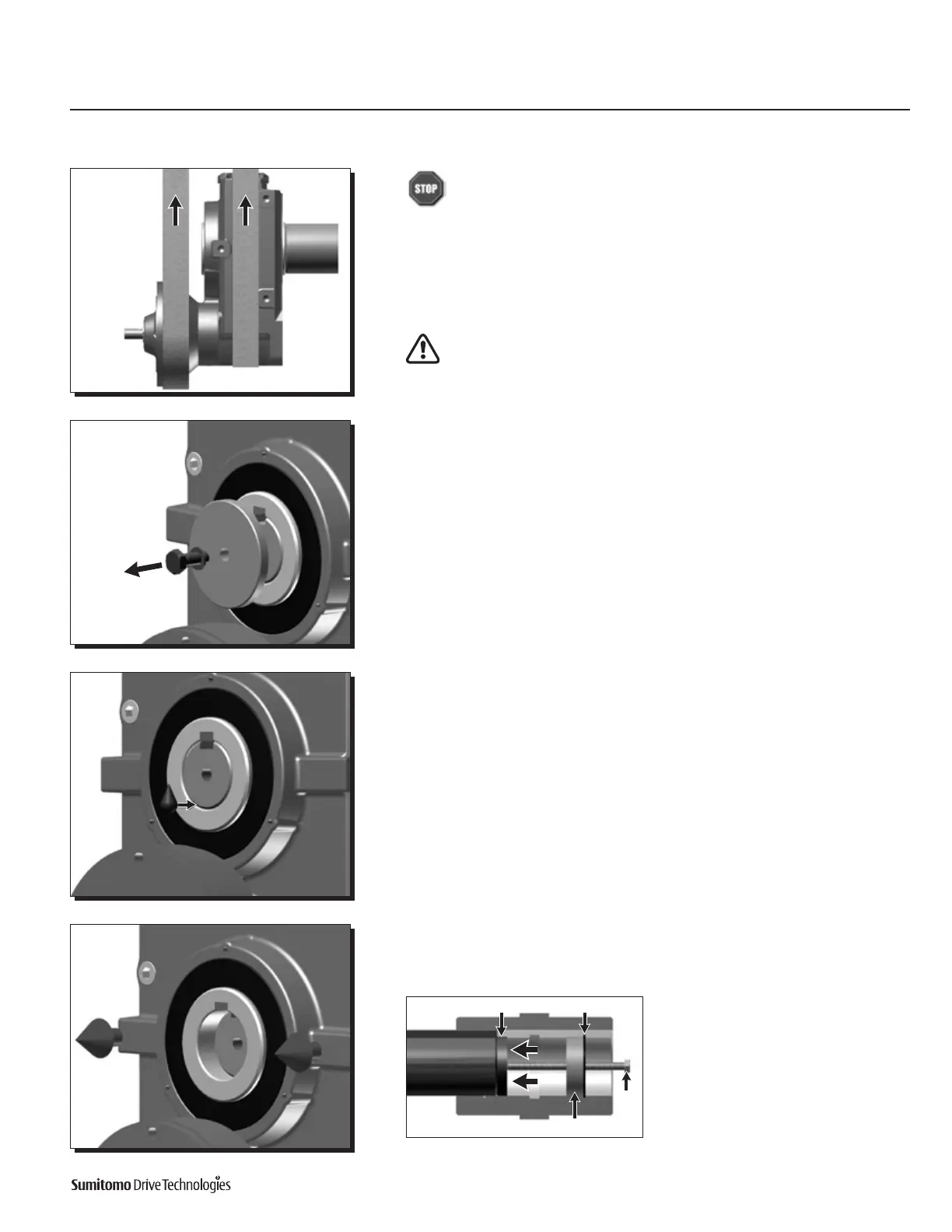

Removal from Driven Shaft

Cyclo® HBB with Keyed Hollow Bore

Before starting unit removal process, ensure that electrical power to unit has

beensafelylockedoutandthatelectricalconnectionstotheunithavebeen

disconnected.

1

Externally support the Cyclo® HBB so that all the unit’s weight is removed from the

driven shaft.

The weight of the Cyclo® HBB must be externally supported throughout the

entire removal process.

Do not raise the unit too high! Shaft binding may occur.

2

Carefully remove the shaft-retaining device from the driven shaft.

3

Applyaliquidpenetranttotheshaftwhereitcontactsthekeyedhollowbore.

Allowtimefortheliquidtopenetratebetweentheshaftandthewallofthekeyed

hollow bore.

4

Once the penetrant has settled adequately, carefully remove the Cyclo® HBB from

the driven shaft.

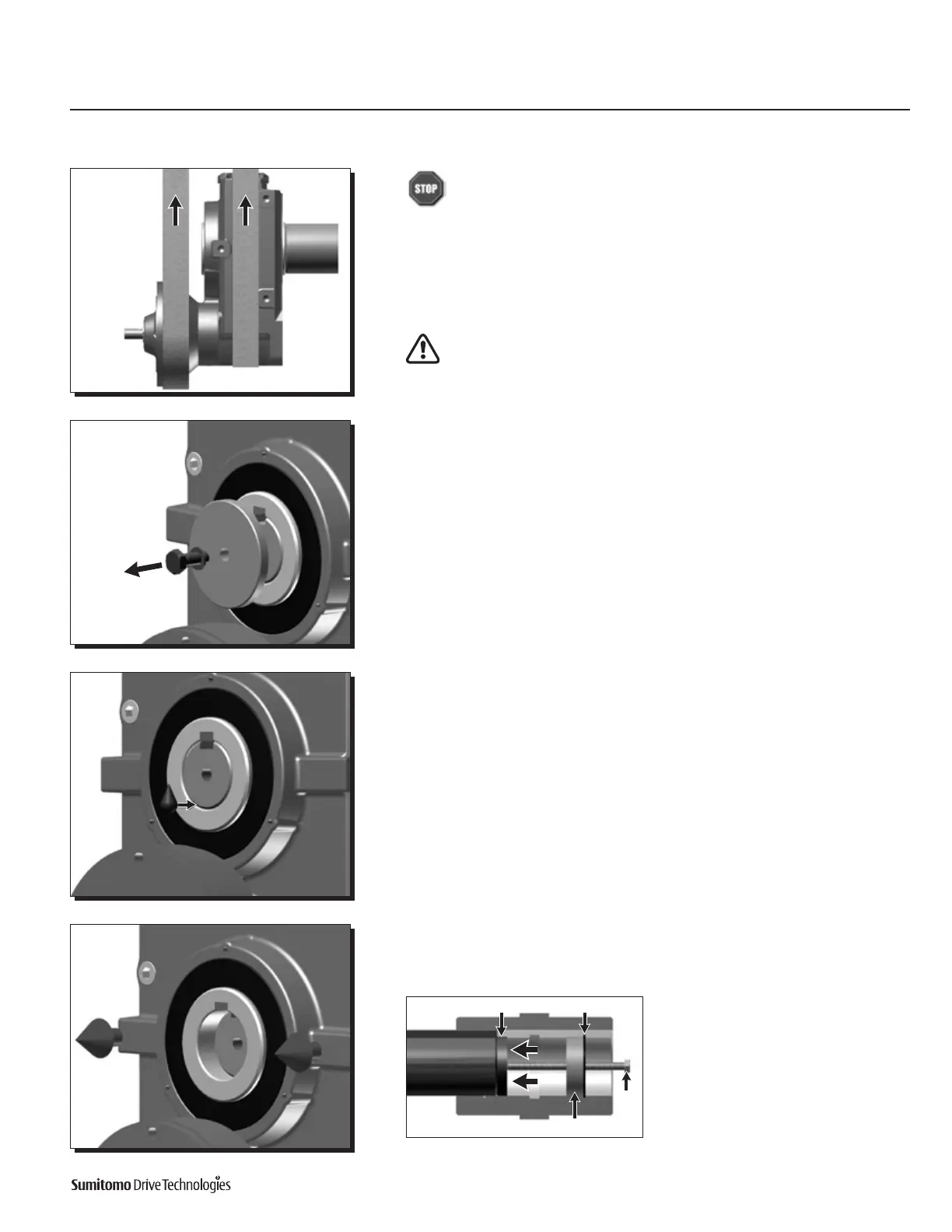

Note: If shaft removal is difficult, a jig

such as the one shown here may be used

to ease the removal process. Sumitomo

Drive Technologies does not supply

the removal jig. This information is

supplied for reference only.

Internal Snap Ring

Spacer: Threaded and Keyed

Bolt

Thrust Disc

Loading...

Loading...