Cyclo® HBB

Operation & Maintenance Manual 19

Cyclo® HBB

Removal from Driven Shaft

Cyclo® HBB with Taper-Grip® Bushing

Before starting the removal process, ensure that electrical power to the unit

hasbeensafelylockedoutandelectricalconnectionstotheunithavebeen

disconnected.

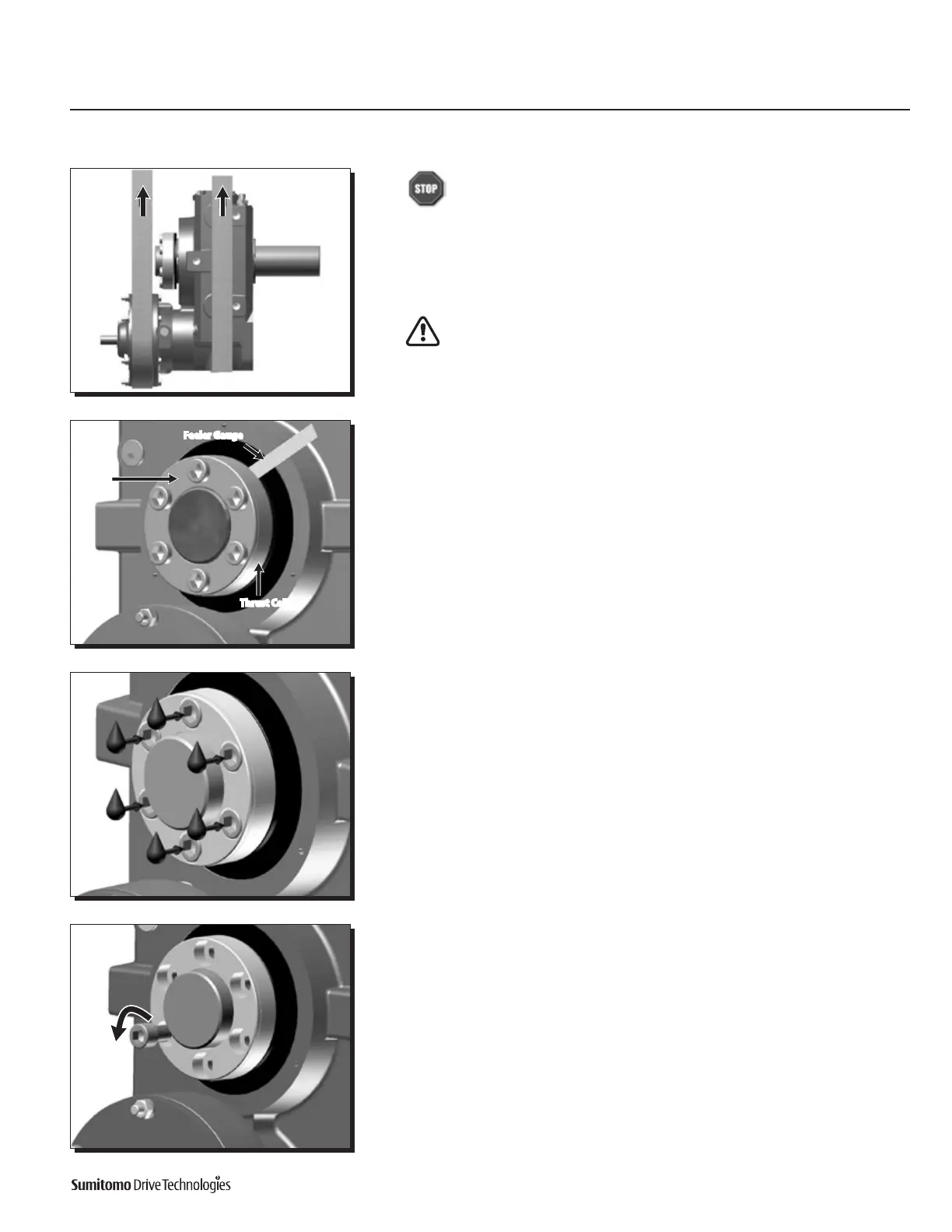

1

Externally support the Cyclo® HBB so that all the unit’s weight is removed from the

driven shaft.

The weight of the Cyclo® HBB must be externally supported throughout the

entire removal process.

Do not raise the unit too high! Shaft binding may occur.

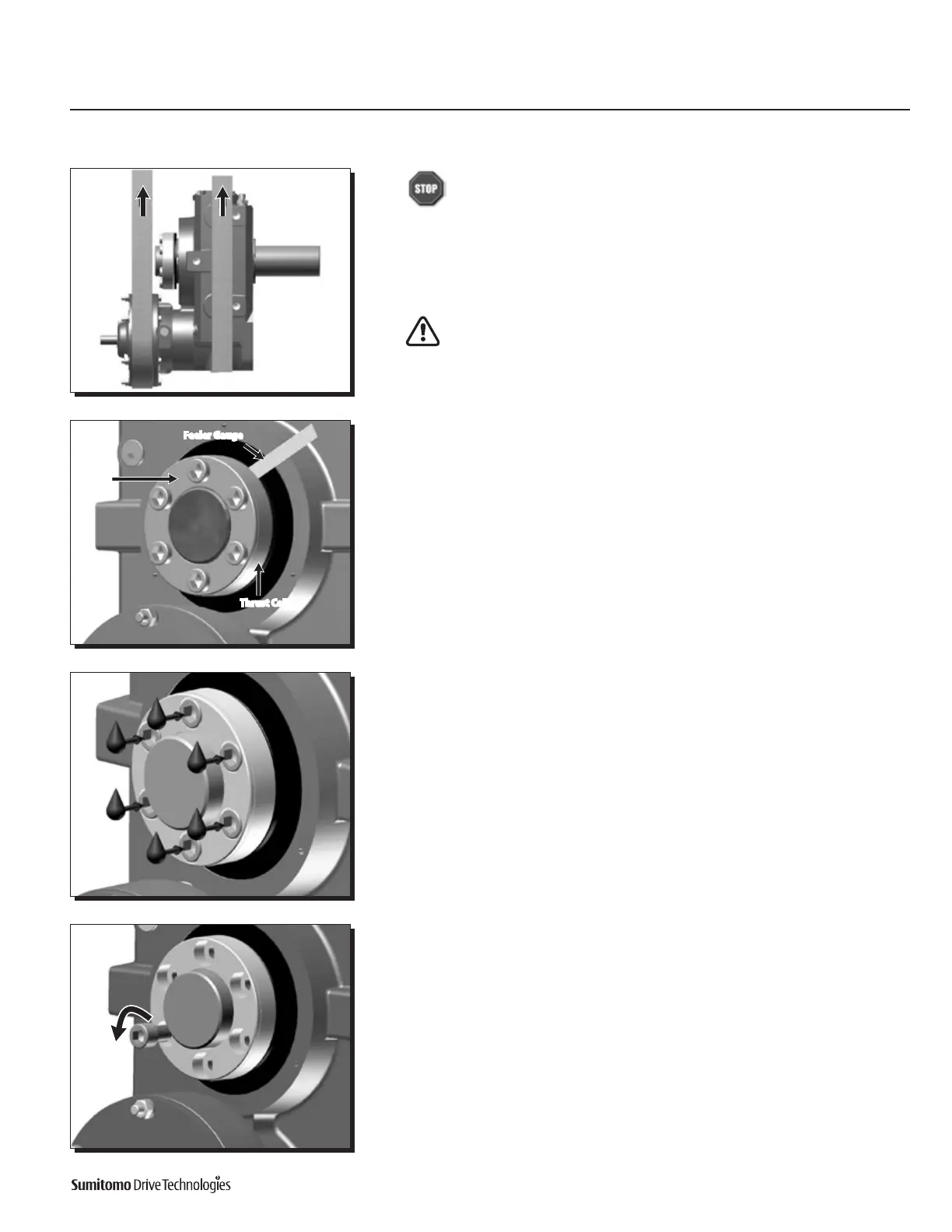

2

Inspect the Taper-Grip® Bushing to assure that a gap exists between the thrust collar

and the bushing flange.

3

Applyaliquid-penetrantontoeachoftheTaper-Grip®Bushingsocket-headcap

screws. Allow time for the penetrant to settle into the threads of the screws.

4

Afterthepenetranthassettled,removethesocketheadcapscrews

one at a time.

Bushing

Flange

1-3mm

Feeler Gauge

Thrust Collar

Loading...

Loading...