8 Operation & Maintenance Manual

Cyclo® HBB

Cyclo® HBB

Installation onto Driven Shaft

Taper-Grip® Bushing Installation

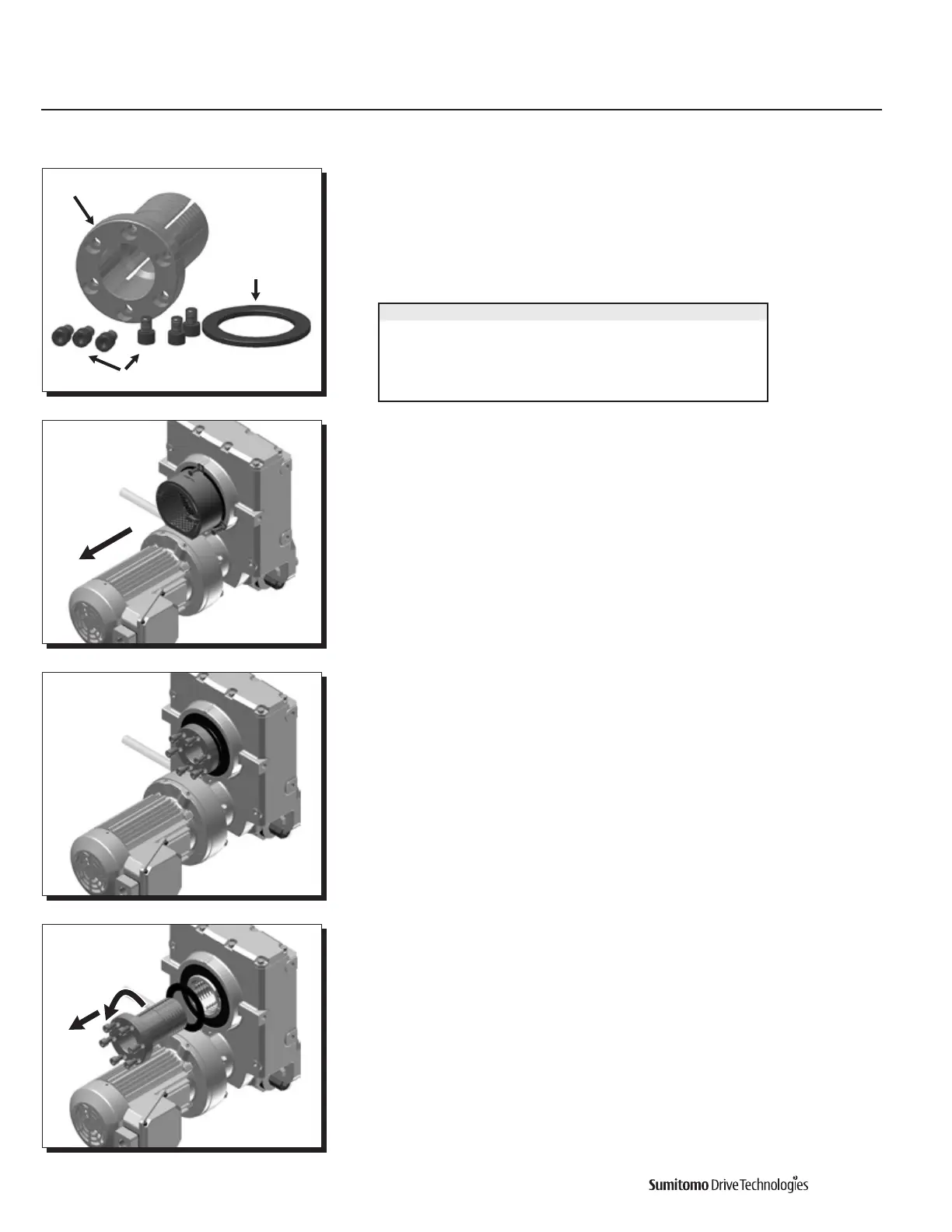

Taper-Grip® Bushing

SocketHeadCapScrews

Thrust Collar

Introduction

ThekeylessTaper-Grip®Bushingsystemprovidessimpleandreliableshaftattachmentfor

Sumitomo speed reducers and gearmotors. This system allows bi-directional shaft rotation

andstop-startoperationwithapowerful,slip-freegrip.Toassurepeakperformanceof

your equipment, please read, understand and follow these installation instructions.

Taper-Grip® Bushing Driven Shaft Tolerances

Parts

As shown in the figure on the left, the Taper-Grip® Bushing includes the bushing,

thrust collar, and socket head cap screws.

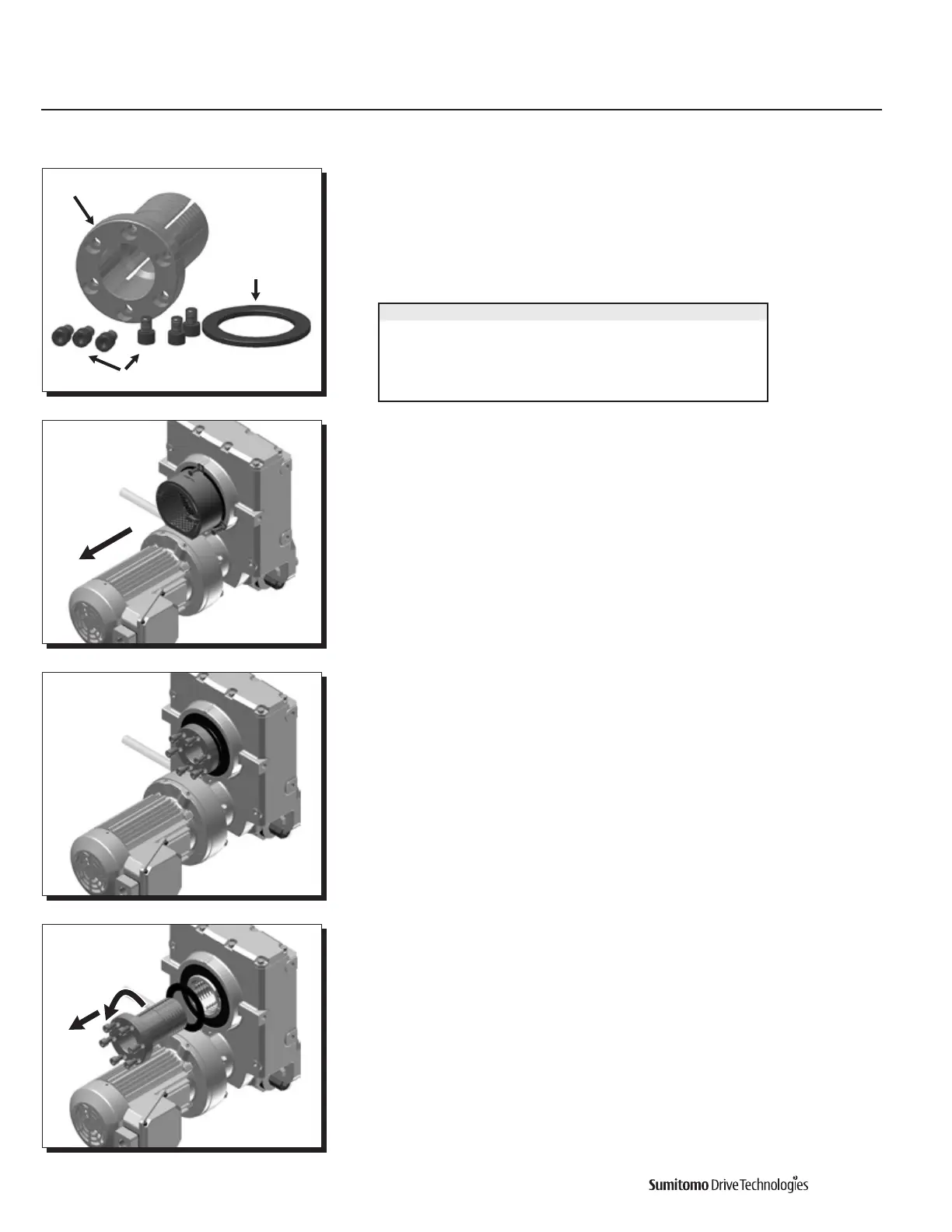

Taper-Grip® Installation onto Driven Shaft

1

Remove the Taper-Grip® bushing safety cover if the unit includes one.

2

Loosen socket head cap screws.

3

Remove (unscrew) Taper-Grip® bushing from the unit. Slide the thrust collar onto the

Taper-Grip® bushing.

Shaft Diameter (inches) Shaft Tolerance (inches)

3

/

4

” — 1

1

/

8

” +0”/ – 0.0013”

1

3

/

16

” — 2” +0”/ – 0.0015”

2

1

/

16

” — 3

1

/

8

” +0”/ – 0.0018”

3

3

/

16

” — 4

3

/

4

” +0”/ – 0.0021”

4

13

/

16

” — 6

1

/

2

” +0”/ – 0.0025”

The required tolerance is h8.

Loading...

Loading...