Cyclo® HBB

Operation & Maintenance Manual 13

Cyclo® HBB

Installation onto Driven Shaft

Keyed Hollow Bore Installation

Keyed Hollow Bore Installation

onto Driven Shaft

1

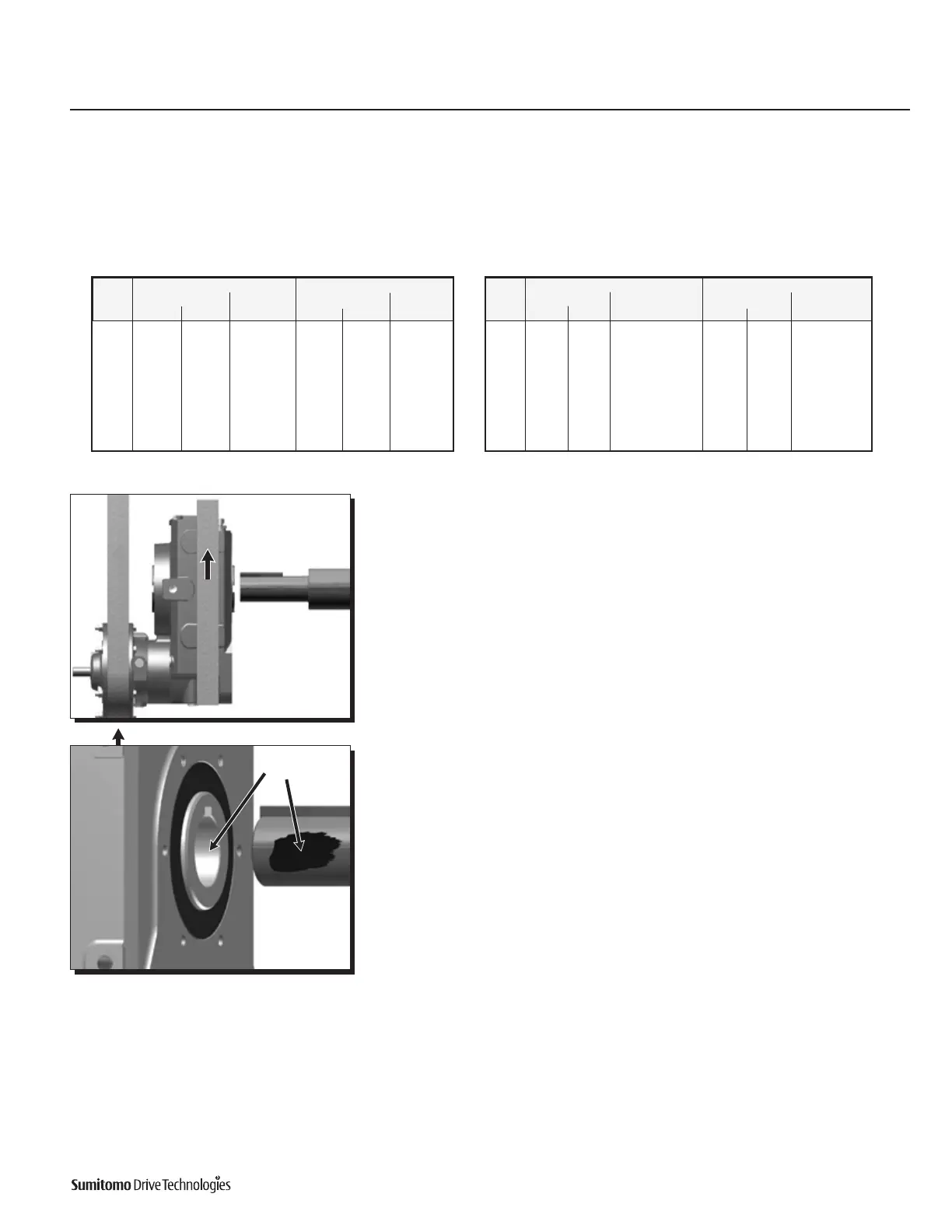

ExternallysupporttheCyclo®HBBbeforeinsertingthedrivenshaftintothekeyed

hollow bore. Maintain external support until the shaft is completely inserted and

secured to the unit.

2

Applymolybdenumdisuldegreasetothedrivenshaftsurfaceandinsidethekeyed

hollow bore.

Grease

Table 4. Driven Shaft Tolerances –

With Shock Load or Large Radial Load

Inch Metric, mm

Frame Shaft Dia

Tolerance

Shaft Dia.

Tolerance

Size Min. Max. Min. Max.

Z 1-3/16 1-1/2 +0.0007 / +0.0001 30 40 +0.018 / +0.002

A 1-3/4 1-15/16 +0.0007 / +0.0001 45 50 +0.018 / +0.002

2 2-3/16 +0.0008 / +0.0001 51 55 +0.021 / +0.002

B 2-3/16 2-5/8 +0.0008 / +0.0001 55 65 +0.021 / +0.002

C 2-7/16 3 +0.0008 / +0.0001 60 75 +0.021 / +0.002

D 2-3/4 3-1/8 +0.0008 / +0.0001 70 80 +0.021 / +0.002

3-3/16 3-7/16 +0.0010 / +0.0001 81 85 +0.025 / +0.003

E 3-3/16 3-15/16 +0.0010 / +0.0001

80 80 +0.021 / +0.002

81 - 100 81 - 100 +0.025 / +0.003

Bore and Shaft Tolerance Specifications

• ThehollowshaftboretoleranceconformstoJISH8,unlessspeciedotherwise.

• SumitomorecommendsashafttoleranceofJISjs6orJISk6iftheapplicationinvolveshighshockloadingand/orlargeradialloads.

Table 3. Driven Shaft Tolerances -

Uniform Load without Shock Load

Inch Metric, mm

Frame Shaft Dia

Tolerance

Shaft Dia.

Tolerance

Size Min. Max. Min. Max.

Z 1-3/16 1-1/2 +0 / -0.0006 30 40 +0 / -0.016

A 1-3/4 1-15/16 +0 / -0.0006 45 50 +0 / -0.016

2 2-3/16 +0 / -0.0007 51 55 +0 / -0.019

B 2-3/16 2-5/8 +0 / -0.0007 55 65 +0 / -0.019

C 2-7/16 3 +0 / -0.0007 60 75 +0 / -0.019

D 2-3/4 3-1/8 +0 / -0.0007 70 80 +0 / -0.019

3-3/16 3-7/16 +0 / -0.0009 81 85 +0 / -0.022

E 3-3/16 3-15/16 +0 / -0.0009

80 80 +0 / -0.019

81 - 100 81 - 100 +0 / -0.022

Loading...

Loading...