Operation & Maintenance Manual 29

Cyclo® HBB

Cyclo® HBB

Grease Replenishment and Draining Procedure

Procedureforaddinggreasetogrease-lubricatedmodels(excludingmaintenance-freemodels)

1. Remove the grease discharge plug from the outside cover.

2. Add grease with a grease gun from the grease nipple in the inside cover section or motor connection cover.

3. Insert the grease discharge plug.

• Addgreaseduringoperationtoensureproper,uniformcirculation.

• Addgreaseslowly.

• DonotaddmoregreasethantheamountshowninTable 17 and 18. Adding too much grease may cause the grease

temperaturetorise,orgreasetoleakintothemotor.

Grease Replacement for Grease-Lubricated and Maintenance-Free Grease Models

•Theunitmaybesafelyoperatedforanextendedtimebecauseitissealedwithmaintenance-freegrease.However,Sumitomo

recommends overhauling every 20,000 hours or 3-5 years of operation to ensure long service life.

•Alwaysconsultourspecializedfactoryforoverhaulofgearmotorsandreducers.Experienceisnecessaryforoverhaul.

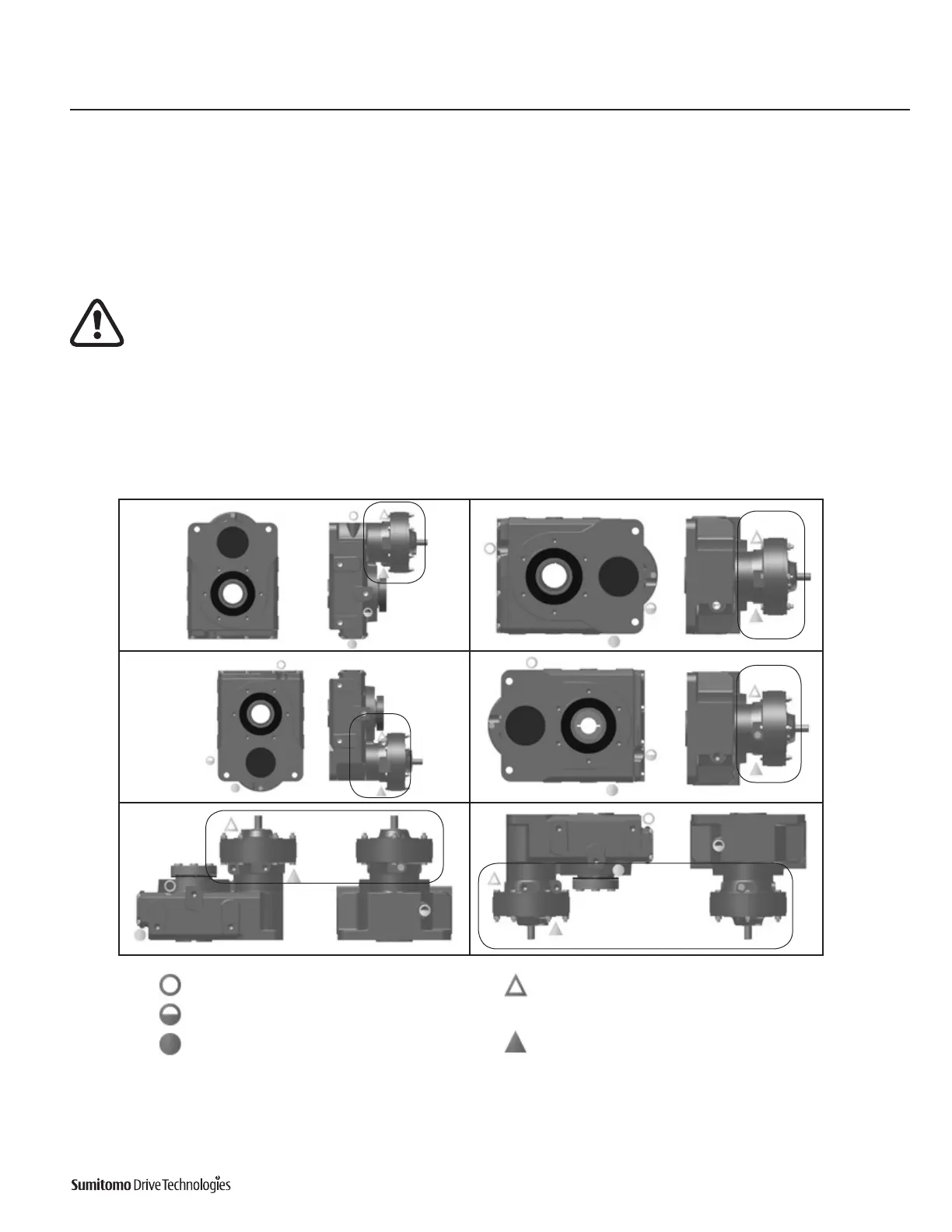

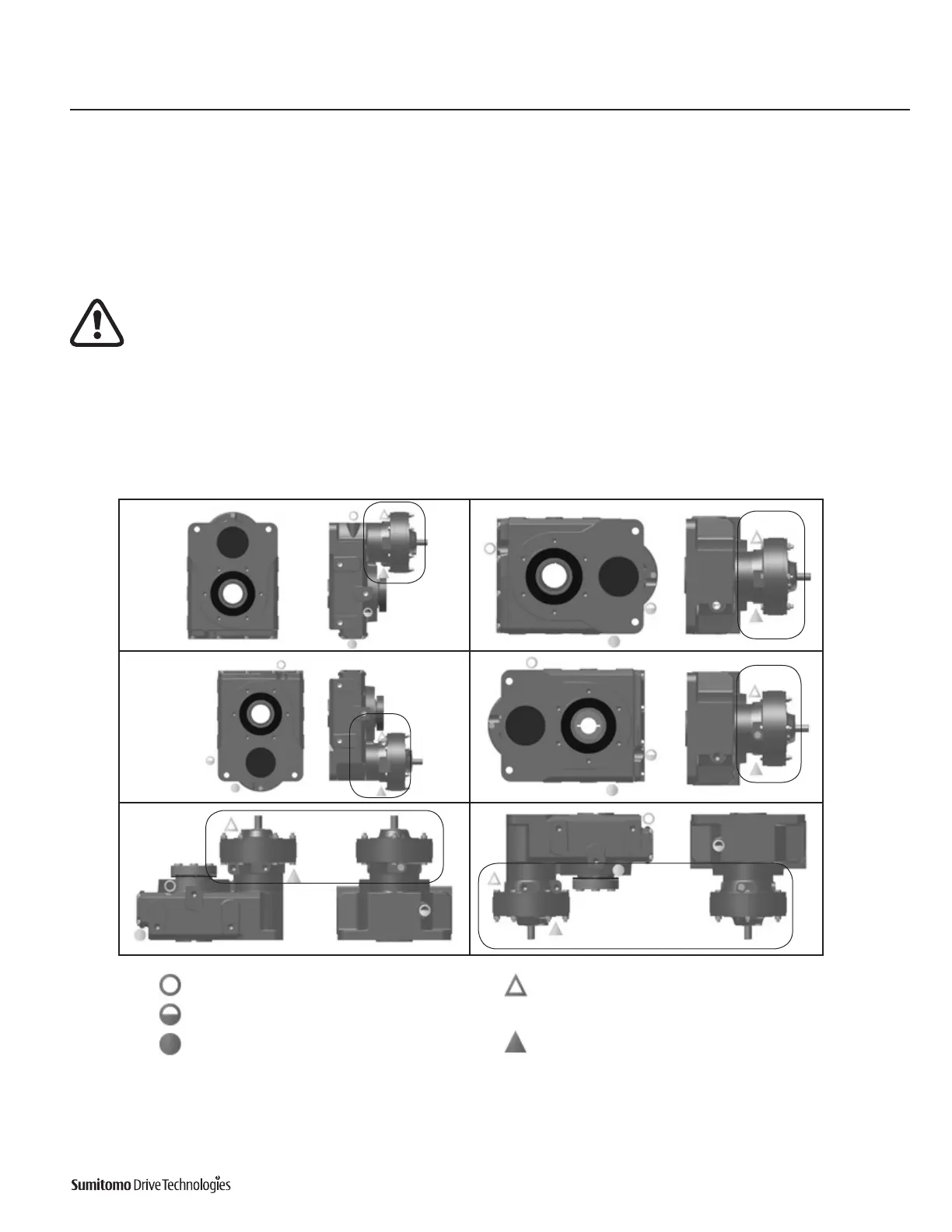

Fig. 5 Grease Fill/Drain Locations

Lubrication

Grease Replenishment / Draining

Y3 Y4

Y1 Y2

Y5 Y6

= Helical Gear Portion Oil Fill Location

= Helical Gear Portion Oil Sight Gauge Location

= Helical Gear Portion Oil Drain Location

= Cyclo® Portion Grease Fill Location

= Cyclo® Portion Grease Drain Location

Loading...

Loading...