Cyclo® HBB

Operation & Maintenance Manual 9

Cyclo® HBB

Installation onto Driven Shaft

Using Taper-Grip® Bushing

4

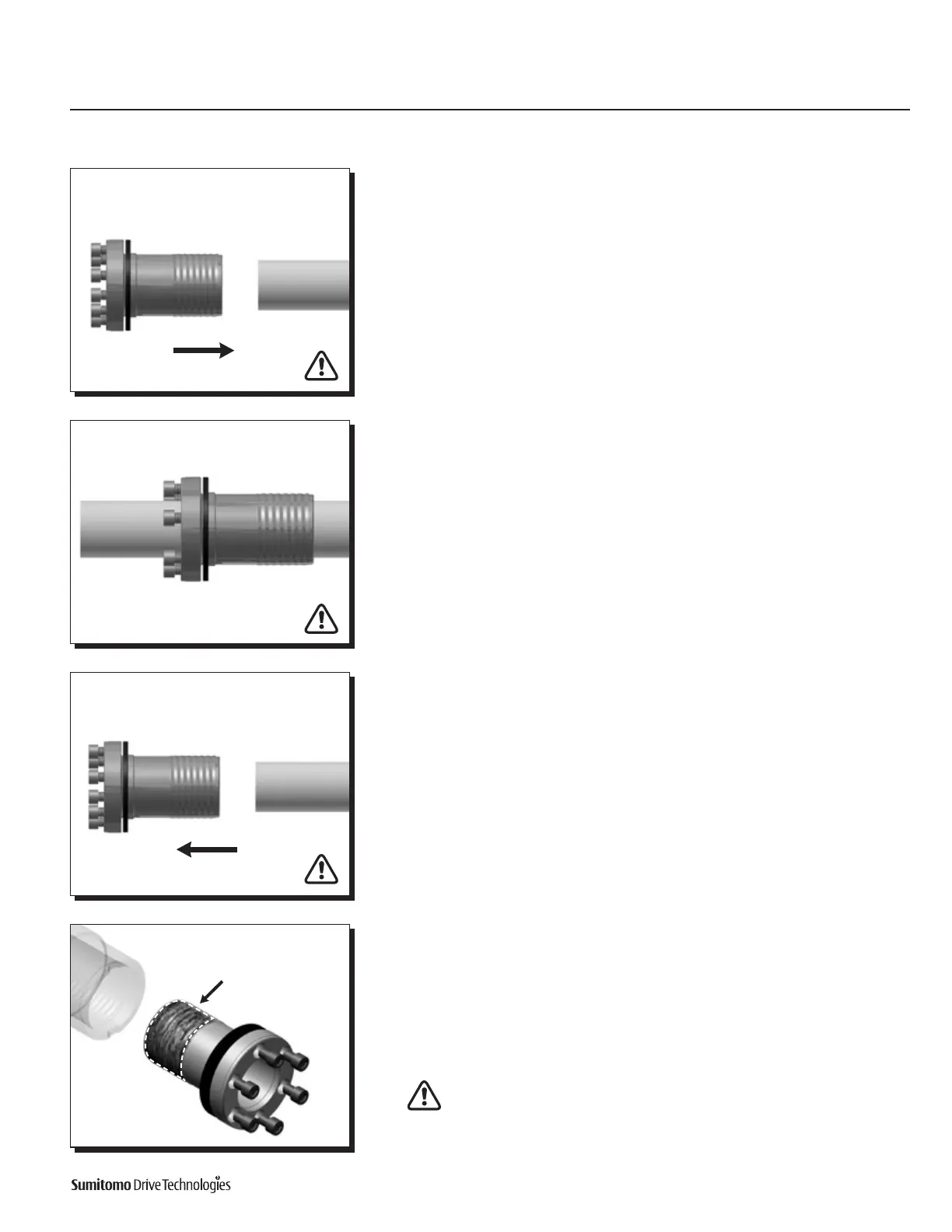

Clean all grease, oil and/or anti-seize paste from the driven shaft. Slide Taper-Grip®

bushing onto driven shaft.

5

Inspect and test Taper-Grip® Bushing on shaft.

• Checkshaftforburrs, corrosion, or warpage. Repair or replace shaft

as necessary.

• Slidebushingbackandforthalongshaft,checkingforsurfaceirregularities

and fit.

• Verifybushingboresize.

6

Remove Taper-Grip® Bushing from driven shaft.

7

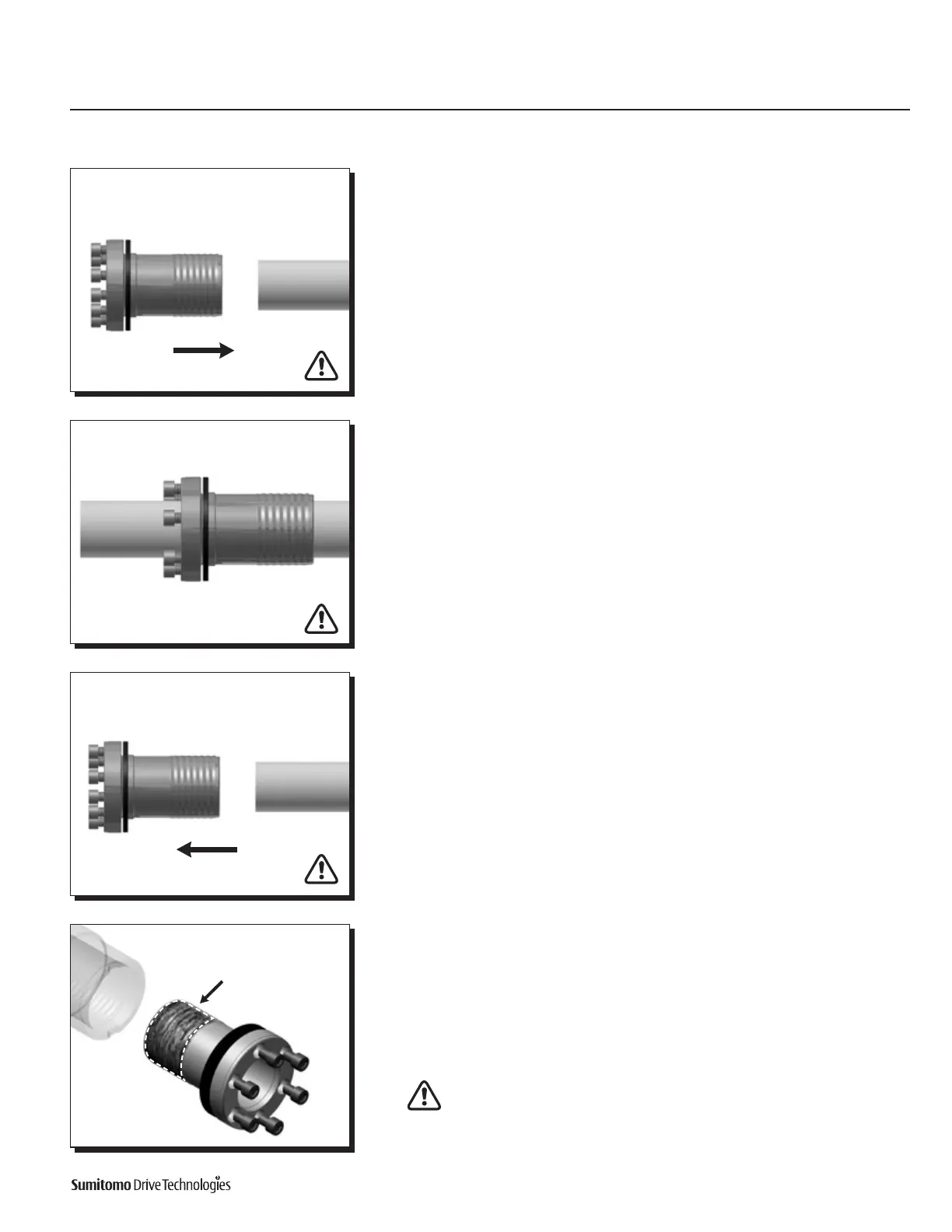

Apply a thin layer of anti-seize paste to the male threads of the Taper-Grip®

bushing only. Ensure that the anti-seize paste does not enter the Taper-Grip®

bushing bore. Carefully thread the Taper-Grip bushing into the hub of the speed

reducer or gearmotor until the thrust collar solidly engages the unit hub surface and

the bushing flange.

Do not apply anti-seize paste to the female threads in the hub.

Apply thin layer of

anti-seize paste to male

threads of bushing only.

Loading...

Loading...