24

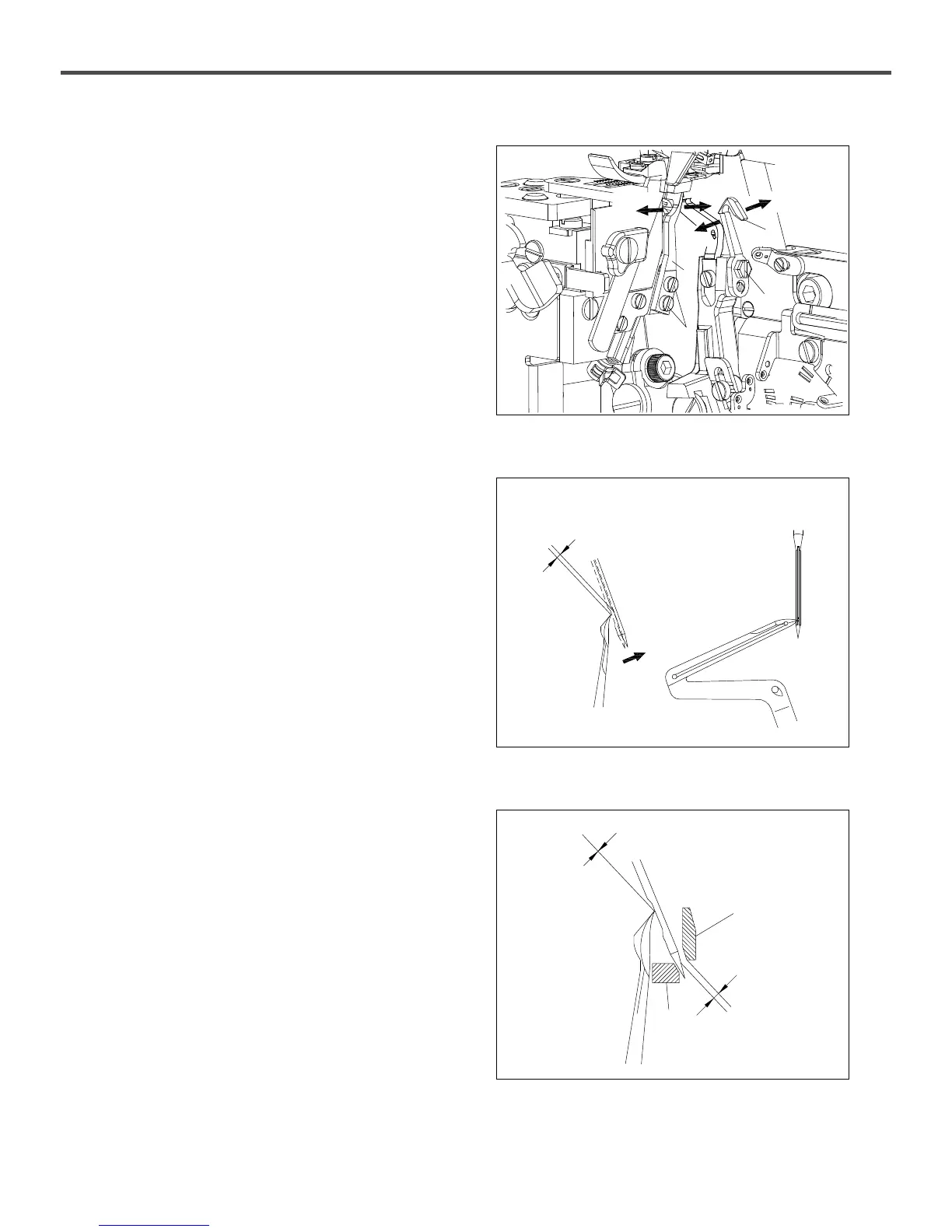

16) NEEDLE GUIDANCE ADJUSTMENT

1) Overlock needle guidance adjustment

When the end of the lower looper reaches to the center-line of

the overlock needle, check the needle is lain aslant

0~0.03mm from the lower looper toward operator.

(Refer to 14) LOWER LOOPER ADJUSTMENT)

•Under the above condition to adjust the needle

guidance(after)①, adjust the needle guidance(after)① to

make the needle on a aslant by the guidance①. The

distance (a) is 0~0.05mm.

To do this, loosen the screw② and move the rear needle

guidance① back/forth as required.

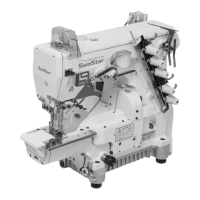

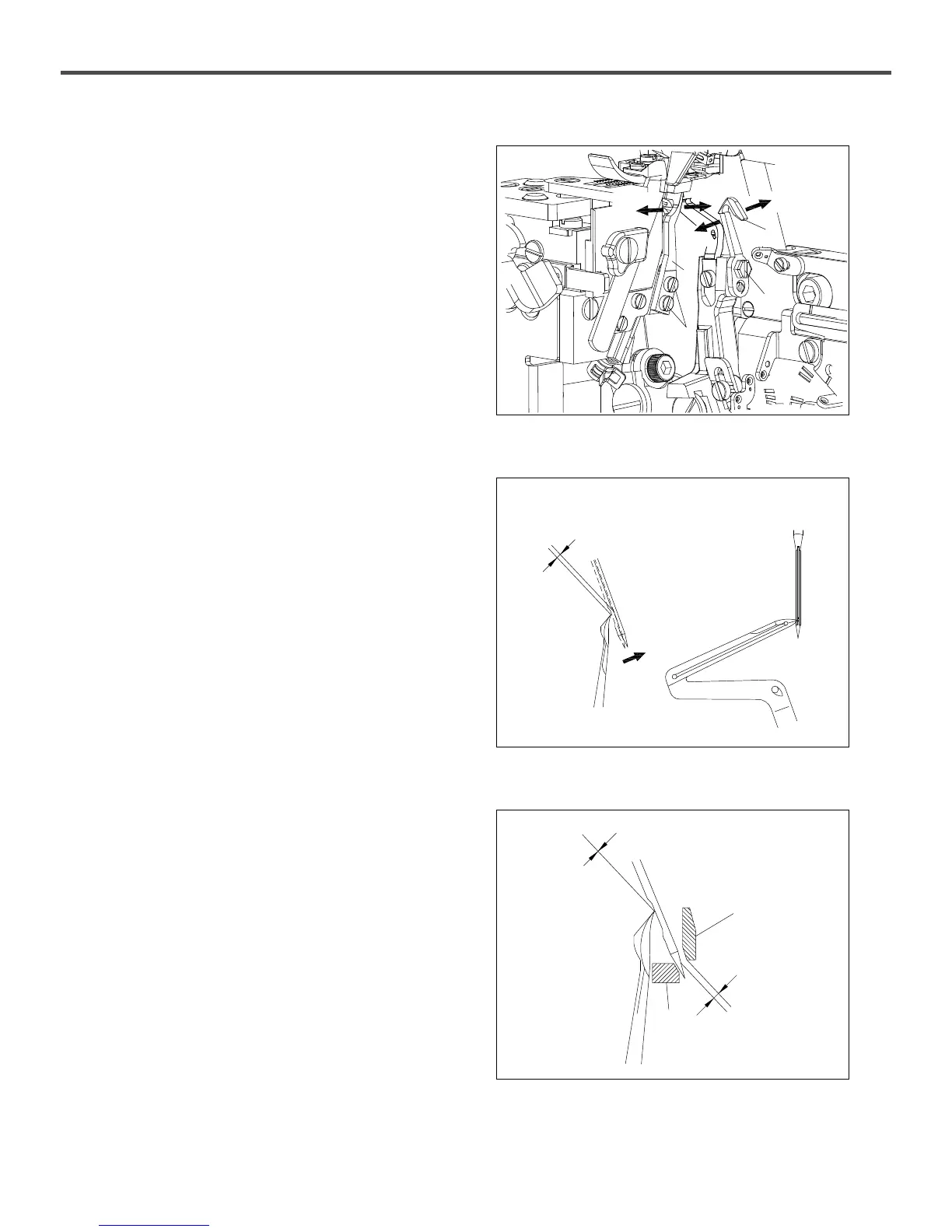

•The end of the lower looper is on the center-line of the

needle to adjust the needle guidance(before) ①. When the

needle is on a slant by the needle guidance(after)①, the

distance(b) between the needle and the needle

guidance(after) is 0.1~0.2mm.

To do this, loosen the screw④ and move the front needle

guidance③ back/forth as required.

[Figure 33]

[Figure 34]

[Figure 35]

0.03~0.05mm

0~0.05mm

0.1~0.2mm

①

②

①

②

③

④

Back

Back

Front

Front

Loading...

Loading...