7-16 Publication: 0028607

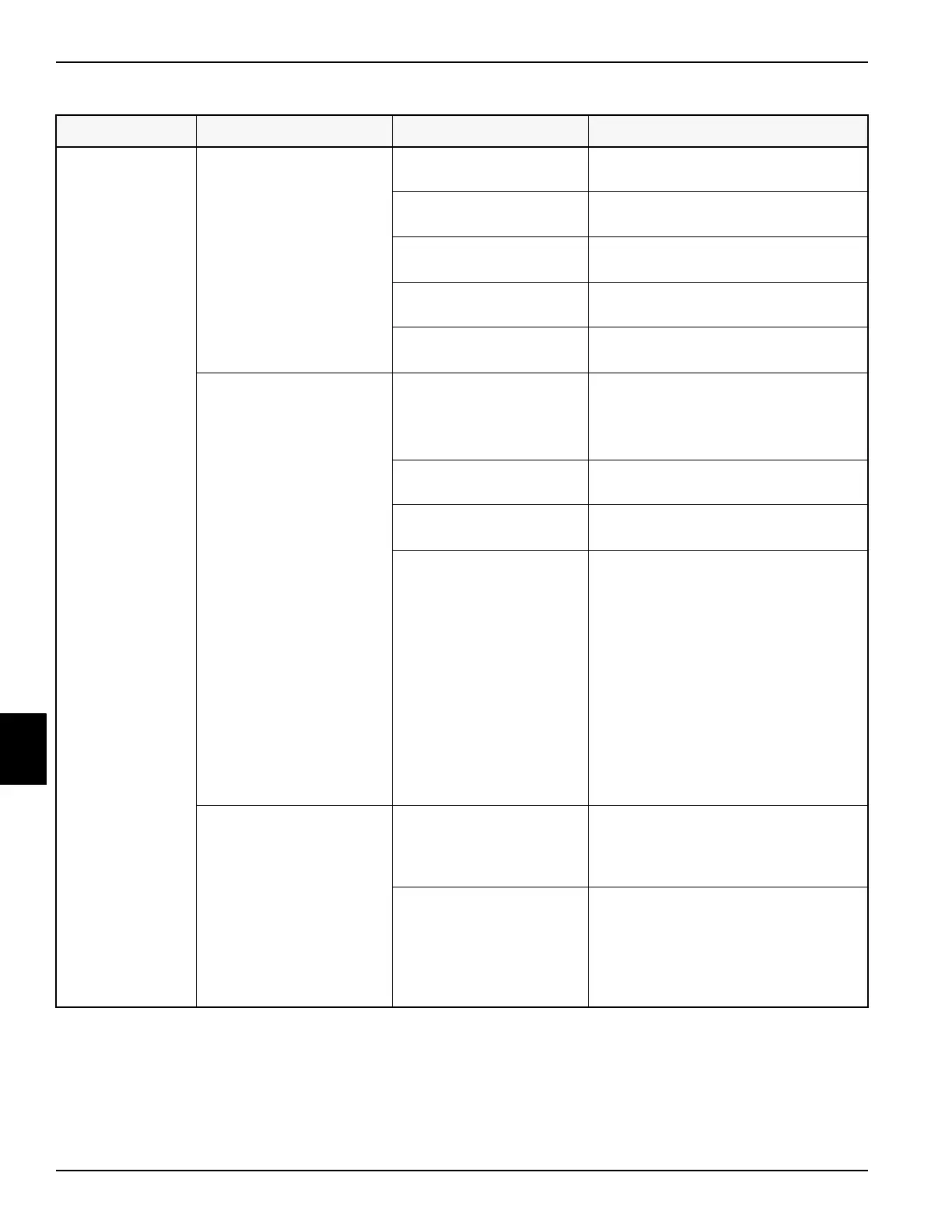

TROUBLESHOOTING

7

Electrical

troubleshooting

basics

(Continued)

Electrical connection

failed

Loss of electrical

connection

Power, signal, or ground return wire

failure.

Cut, broken, or dislodged

wire

Locate and repair or replace.

Connector pin not fully

seated inside connector

Reseat pin into connector.

Wire pulled out of

crimped pin

Locate and repair or replace.

I/O module has failed to

operate

Check module power or power input

LEDs.

Analog signal not working Special control signal not

readable with a voltmeter

• Check the diagnostic screens to

view input and output status.

• Green indicates on; white

indicates off.

Wires connected to

wrong pin location

Check wiring against the drawing to

determine where the signal is lost.

Loose wire connection • Connect an incandescent lamp to

the circuit and wiggle wires.

Device failed • Using wire jumpers, temporarily

connect power and ground to get

device to work.

CAUTION: Incorrect wiring may

damage device.

• Check LEDs on device.

• Replace device.

• LED light on proximity sensor

should light up when it senses

steel.

• Ensure that LED light polarity is

connected correctly.

Function will not work

using wired or wireless

pendants

Electrical coil failure If the directional solenoid LEDs are lit

but function does not move, try again

by setting the manual override on the

proportional valve.

Electrical malfunction. If

at least one of the control

devices makes the

function work properly,

the root cause is not

hydraulic

If the function works with manual

override, and the LED light on the coil

connector lights up, the solenoid coil

may have failed and will need to be

replaced.

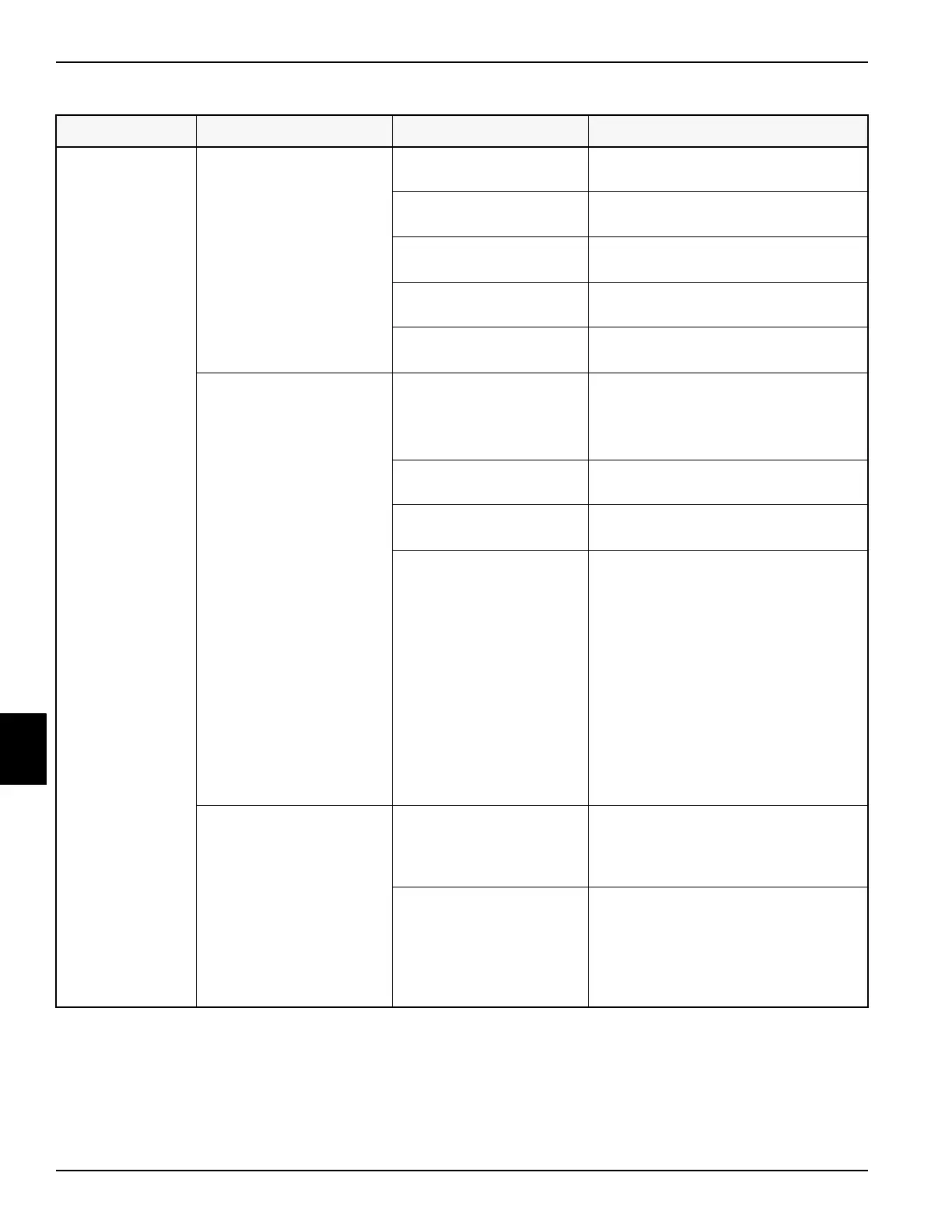

Table 7-2: Electrical Troubleshooting (Continued)

Function Symptom Probable Cause Solution

Loading...

Loading...