1-20 Publication: 0028607

SAFETY

1

VACUUM RELIEF VALVE SAFETY — CONTINUED

Testing the T-Type Vacuum Relief

Valve

The following test should be done every time the

vacuum relief valve is assembled into the vacuum

inlet line or every two hours of during operation,

whichever is more frequent.

1. Visually inspect the vacuum relief valve, pull cord,

and safety belt. Repair or replace as needed.

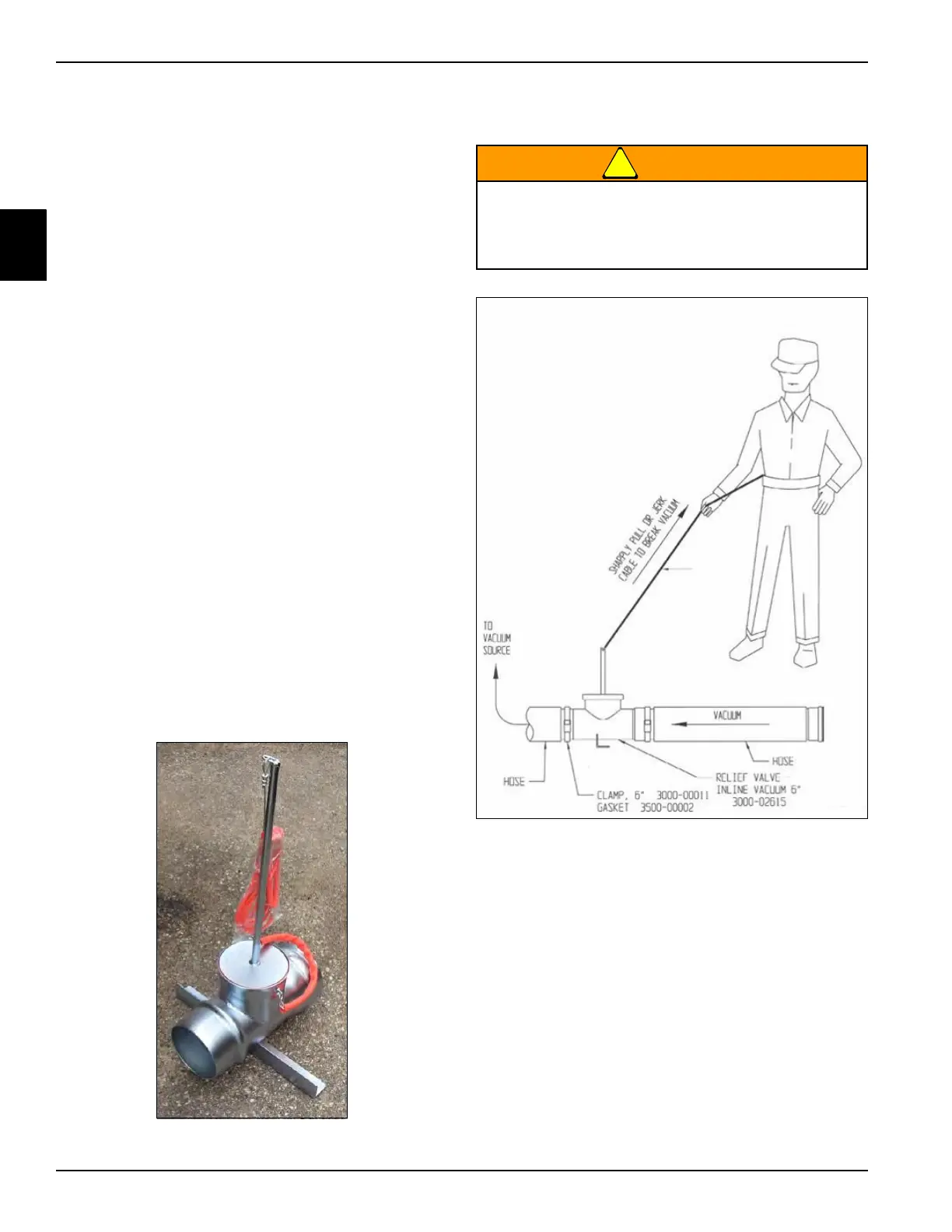

2. With the vacuum pump shut down and the truck’s

engine turned off, assemble the vacuum relief valve

in the vacuum inlet line as shown in Figure 1-20.

Attach the pull cord to the vacuum relief valve.

3. Insert the male plug into the end of the vacuum relief

valve or vacuum inlet hose, whichever is at the inlet

point.

4. With the vacuum relief valve closed, start up the

vacuum pump and pull full vacuum.

5. At full vacuum, pull the cord to open the vacuum

relief valve.

6. After the test, shut down the vacuum pump per

operating procedure.

7. Open the vent door to make sure all vacuum is

relieved before removing the plug from the end of the

vacuum inlet hose.

8. Reset the vacuum relief valve. Remove and store the

vacuum relief valve if it is not going to be used.

Figure 1-19

Figure 1-20

If the vacuum relief valve is not working properly,

personnel should not be allowed to work at the

end of the vacuum inlet hose due to possible

injury or death.

Loading...

Loading...