18 SUPERBRUSH OWNER’S MANUAL

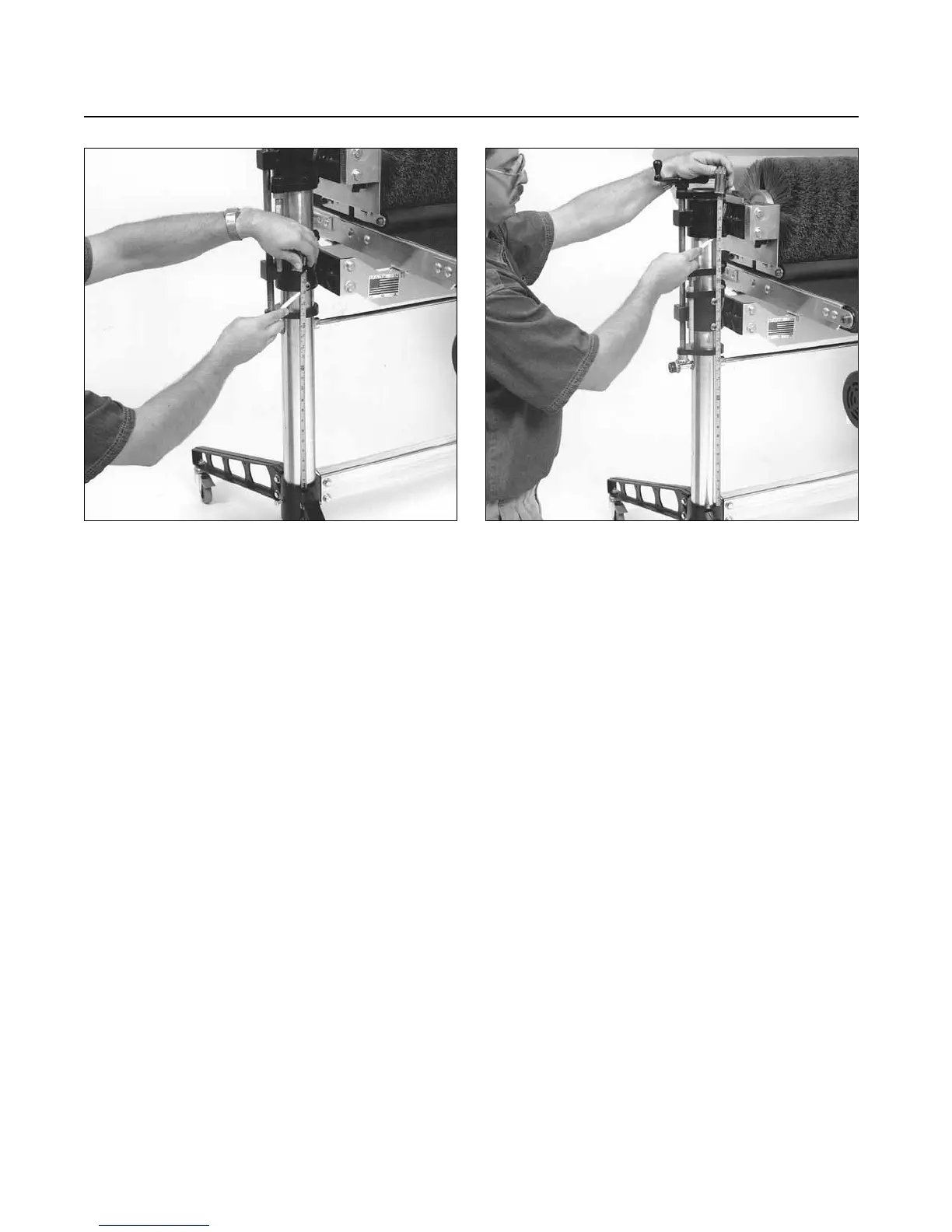

LEVELING TABLE

To measure levelness of table, measure the distance

between the top of the base casting (Fig. 17) and

the bottom of the table support castings. This

measurement should be the same for both sides. If

it is not the same, adjust as follows:

Remove the plastic cap from the miter gear (Fig.

14) on the outboard side of the machine. Loosen

the set screw of the miter gear and slide it back to

disengage it from the miter gear of the adjusting

screw. Turn the adjusting screw handle to raise or

lower the outboard side of the table so that the

measurement taken above equals the inboard side

of the table. After adjusting is complete, re-engage

miter gear making sure that miter gear set screw is

aligned with flat on cross bar shaft.

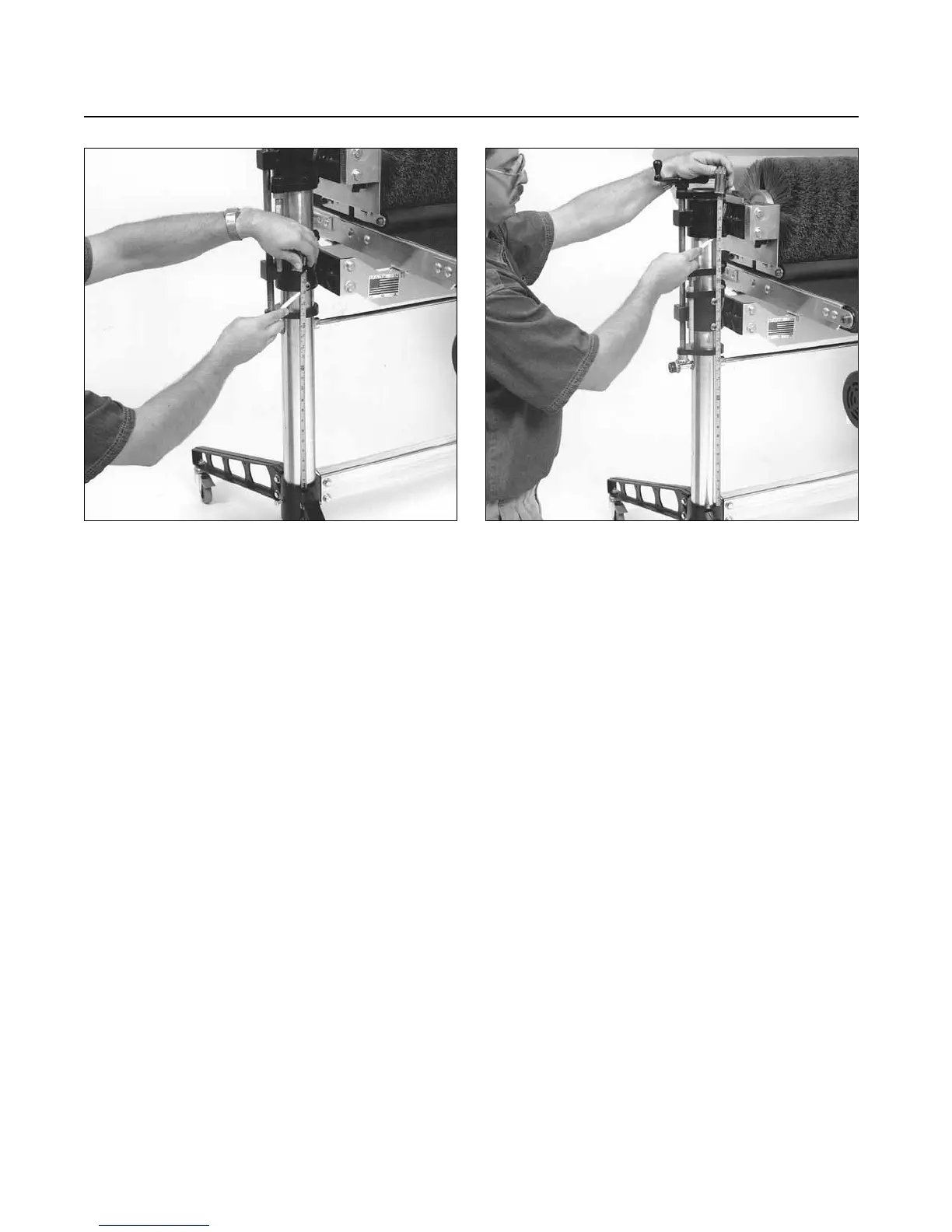

MITER GEAR ALIGNMENT

If height adjustment mechanism does not operate

easily, perform the following checks or adjustments:

1. Loosen set screws located on table support

castings. (Fig. 3).

2. Lubricate thoroughly! Apply penetrating lubricant

to table support castings where it contacts the

column tubes, and to all contact points of adjusting

screws and cross bar. Apply grease/oil to miter

gears.

3. Check miter gear alignment. Check and adjust

gears so that gear mesh is not too tight nor too

loose and that gear teeth align with opposing gear.

The miter gears can be adjusted on their shafts by

loosening the set screws on the gears. Note that set

screws MUST align with flat of shaft. To raise or

lower the vertical miter gears, the adjusting screw

support, located immediately above the gears,

must also be raised or lowered to ride on top of the

gear to maintain adjusting screw position.

If vertical miter gear is raised to its highest

position, then the adjusting screw (Fig. 5) must be

raised, if necessary, to obtain proper gear alignment.

Raise adjusting screws as follows:

Fig. 18. Comparing brush support casting heights.Fig. 17. Adjusting table support castings.

Loading...

Loading...