20 SUPERBRUSH OWNER’S MANUAL

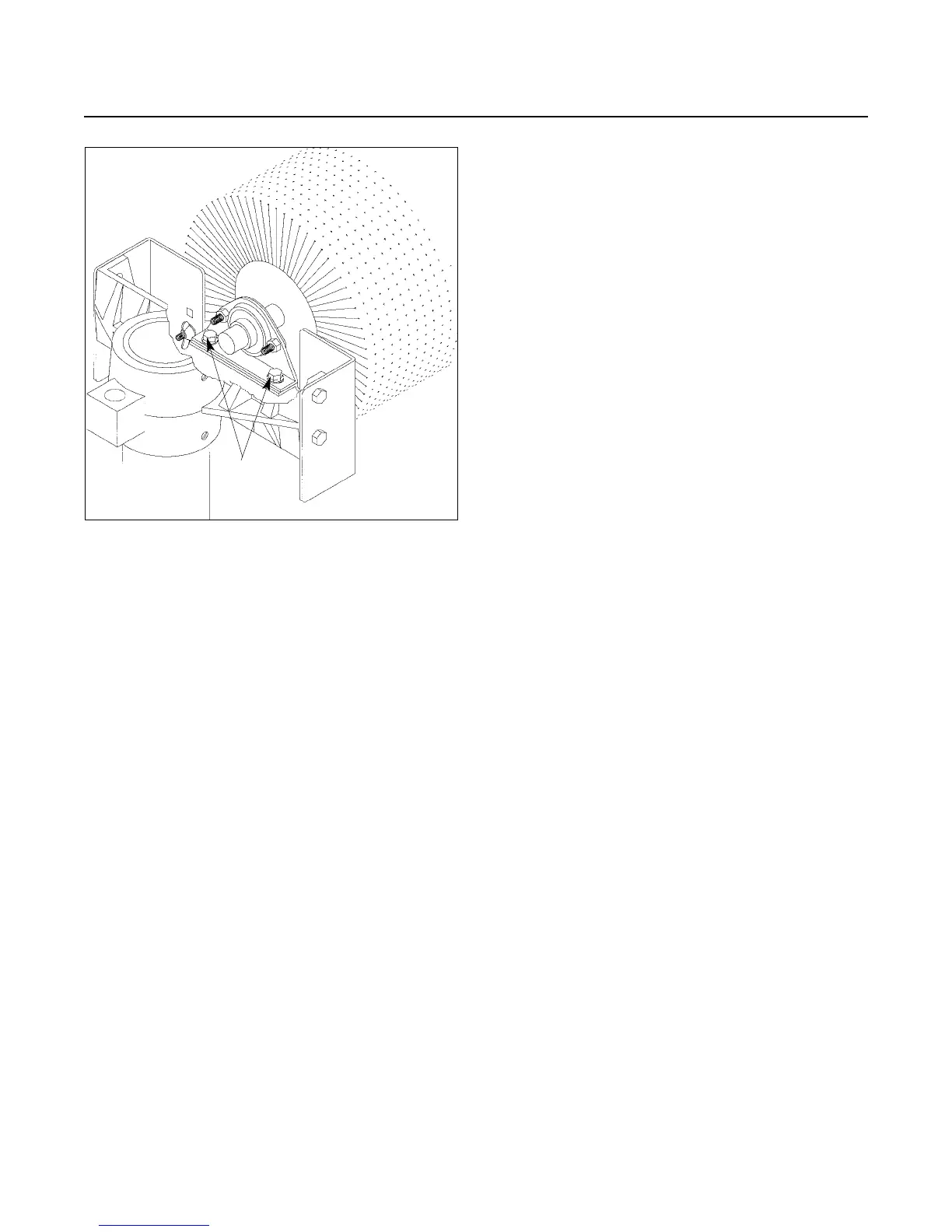

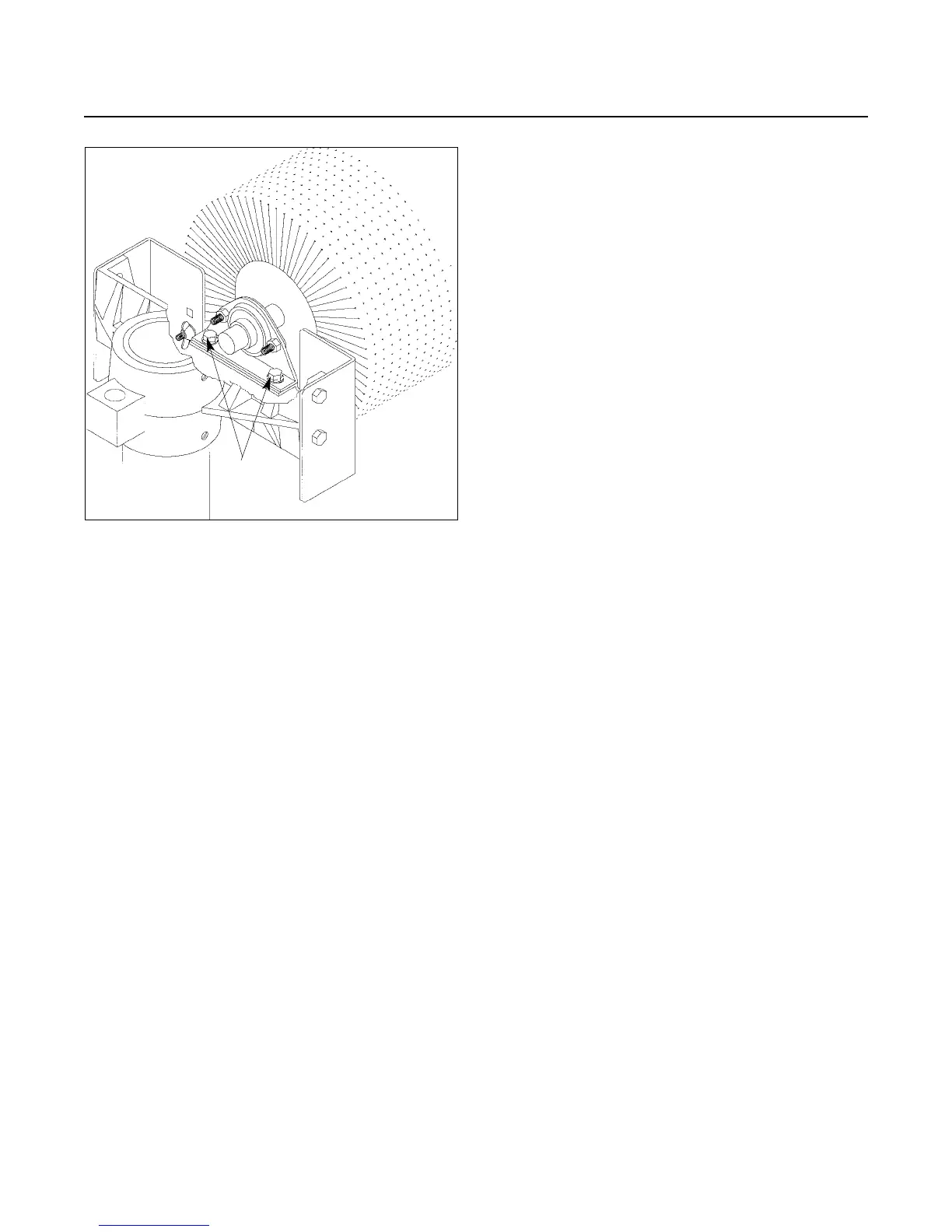

CHANGING OR REPLACING BRUSH

Changing the brush on the SUPERBRUSH is relatively

simple. To begin, first disconnect power source to

the machine. Lower the motor to its lowest position

using the brush speed control handle. Raise the

motor to its highest position. This loosens the

V-belt tension so the V-belt can be lifted off the

driven pulley, pulled back and placed under the

control handle to hold it out of the way. Loosen

and remove bearing bolts (Fig. 19 and 19A,

depending on model. See also page 23 and Fig.

25.) Lift brush out of machine. Loosen set screws

of bearing collars and pulley. Remove bearings and

pulley and install on replacement brush.

Install replacement brush in machine and center

brush before tightening bearing bolts. Tighten

bearing set screws after bearing bolts are tightened.

Install V-belt on driven pulley and adjust pulley

for proper V-belt alignment before tightening

pulley set screw.

REPLACING CONVEYOR BELTS

To replace the conveyor belt, the conveyor assembly

must be removed from the machine. Lower the

conveyor table to its lowest position with the

height adjustment handle. Turn off power source

to machine. Place conveyor motor assembly on

top of dust cover (see #3, page 5). Loosen the

conveyor take-up screws (Fig. 21) to relieve belt

tension and slide the driven roller fully inward.

Remove the four bolts that attach the conveyor

assembly to the table mount brackets (see Fig. 21).

Lift the conveyor and remove it from the machine

by sliding the conveyor out toward the front of the

machine. Avoid tearing the belt on any edges

underneath the conveyor bed during removal.

Reverse the procedure for re-installation.

Note: If the conveyor belt continually tracks to

one side of the machine, first try reversing the belt

on the conveyor bed. If this doesn’t remedy the

problem, place a level on the conveyor bed to

make sure the conveyor bed is not twisted. If it is

twisted, see page 7 for instructions on squaring up

the bed. If squaring up the bed does not remedy

the problem, proceed with the steps below:

Step 1. Check the conveyor drive and driven roller

to make sure it is parallel to the surface of the

conveyor bed. To do this, first center the conveyor

belt on the bed. Then lay a straight-edge on the

exposed edge of the conveyor table on the left

(outboard) side, extending it over the drive or

driven roller. Note the distance between the drive

or driven roller and the straight-edge.

Step 2. Now repeat Step 1 on the right (inboard)

side of the conveyor. Compare the measurements

from side to side. If they are not equal, loosen one

of the brackets that hold the drive or driven roller

in place. Tip this bracket until the distance

between the drive roller and the straight-edge are

equal from side to side, then tighten the bracket.

Fig. 19A. Removing brush head (some models).

BRUSH

MOUNTING

BOLTS

Loading...

Loading...