SERVICING YOUR SUPERBRUSH 19

Inboard follow screw (right): Loosen and raise

adjusting screw support (Fig. 5).Loosen both set

screws located on front of brush support casting

and raise inboard side of brush, screw and table to

desired height. Retighten set screws of brush support

casting (Fig. 3) and re-position and tighten

adjusting screw support at top of miter gear. The

brush and conveyor table must be re-aligned after

this adjustment. See Leveling Table and Brush

Alignment (page 7).

Outboard Adjusting Screw (left): Loosen and raise

adjusting screw support (Fig. 5) above miter gear.

Tighten set screw at front of outboard table support

casting. Loosen set screw and disengage opposing

horizontal miter gear. Turn adjusting screw handle

to raise screw to desired height. Re-position

adjusting screw support to bottom of handle.

Re-position adjusting screw support (Fig. 17) to

top of miter gear. Loosen set screws of table support

casting (Fig. 3). Re-engage opposing horizontal

miter gear. NOTE: Shaft collars (Fig. 10) located

on the transfer rod should be adjusted to control

lateral movement of the transfer rod to maintain

accurate miter alignment and mesh.

4. Check and adjust for misalignment of adjusting

screw supports (Fig. 5) and brush support castings

which could cause binding on the adjusting screw.

These castings can be slightly rotated by loosening

the set screws which secure it to the inside of the

column tubes. NOTE: The adjusting screw support

(Fig. 5) located immediately below the height

adjusting handle and the outboard brush support

casting, must be set at the proper height along the

column tubes to position the adjusting screws so

that there is proper miter gear alignment. Before

adjusting these parts, tighten one set screw of table

support castings to maintain adjusting screw

position during adjustment.

BRUSH SPEED ADJUSTMENT

If the brush speed adjustment does not operate

easily, perform the following check or adjustments:

1. Loosen set screws located on front of motor

support casting (Fig. 3).

2. Lubricate thoroughly!! Apply penetrating lubricant

to motor support casting where it contacts the

column tubes and to all contact points between

adjusting screw and adjusting screw supports (Fig.

5).

3. Improper alignment of adjusting screw supports

may cause binding on the adjusting screw. Loosen

both set screws on each adjusting screw support to

rotate or adjust screw supports. Note that adjusting

screw supports control both lateral and vertical

movement of the adjusting screw mechanism and

must be adjusted accordingly.

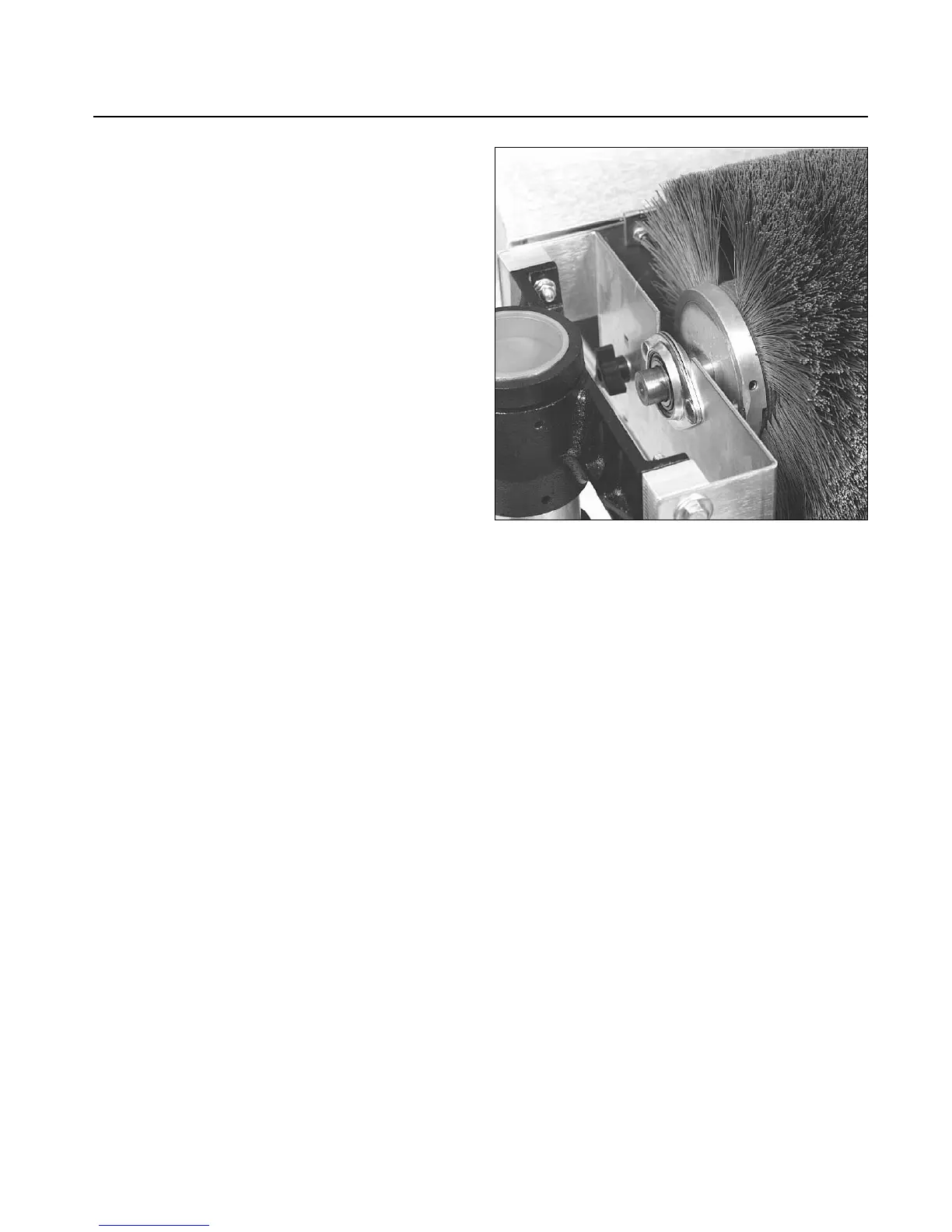

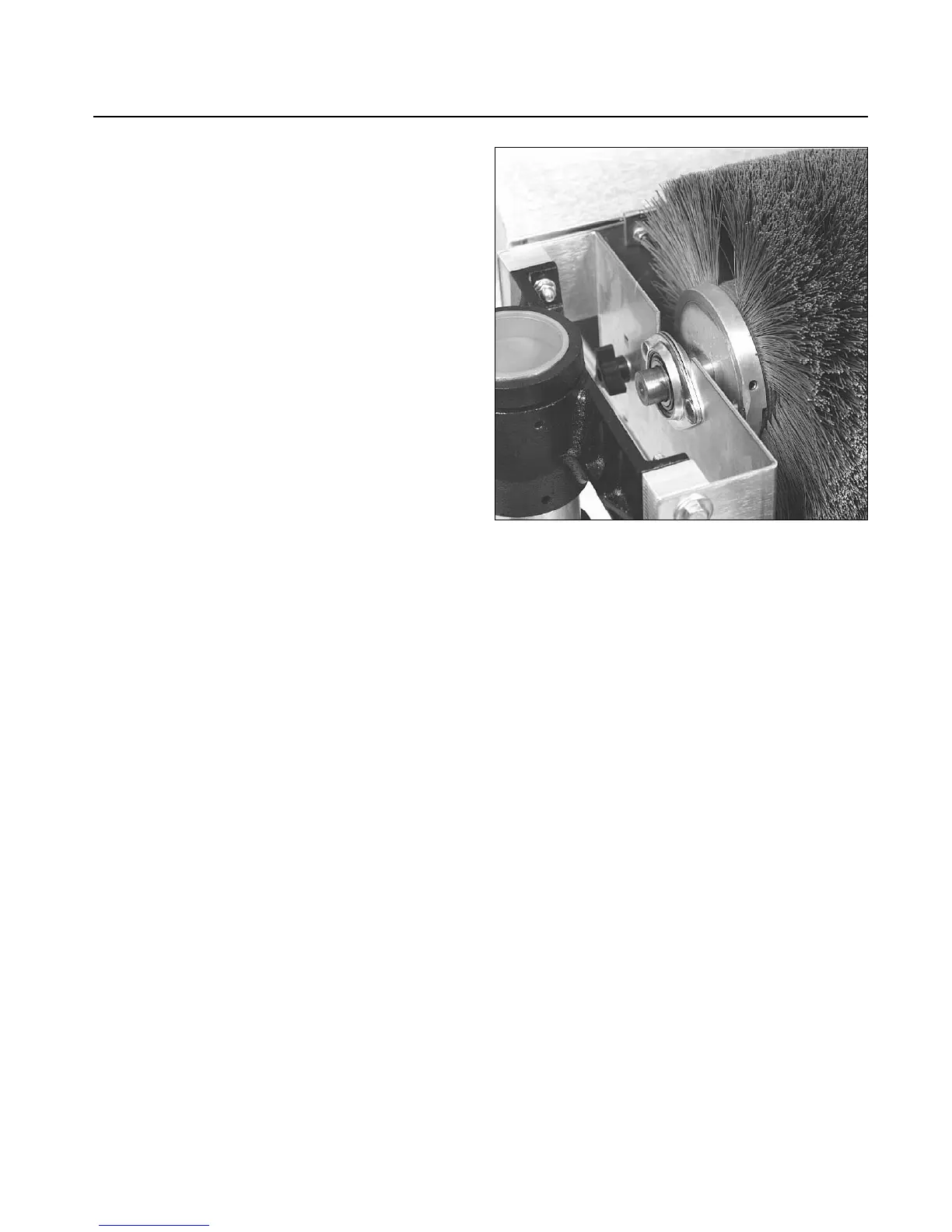

Fig. 19. Removing brush head.

Loading...

Loading...