8 SUPERBRUSH OWNER’S MANUAL

equal across the width of the conveyor. If the

S

UPERBRUSH is properly leveled (See checking

machine for level), brush misalignment can be

corrected by loosening the two set screws at the

front of the outboard brush support casting (Fig.

5) and by raising or lowering casting to correct

alignment.

NOTE: Improper brush alignment will cause

uneven results and lead to reduced brush life.

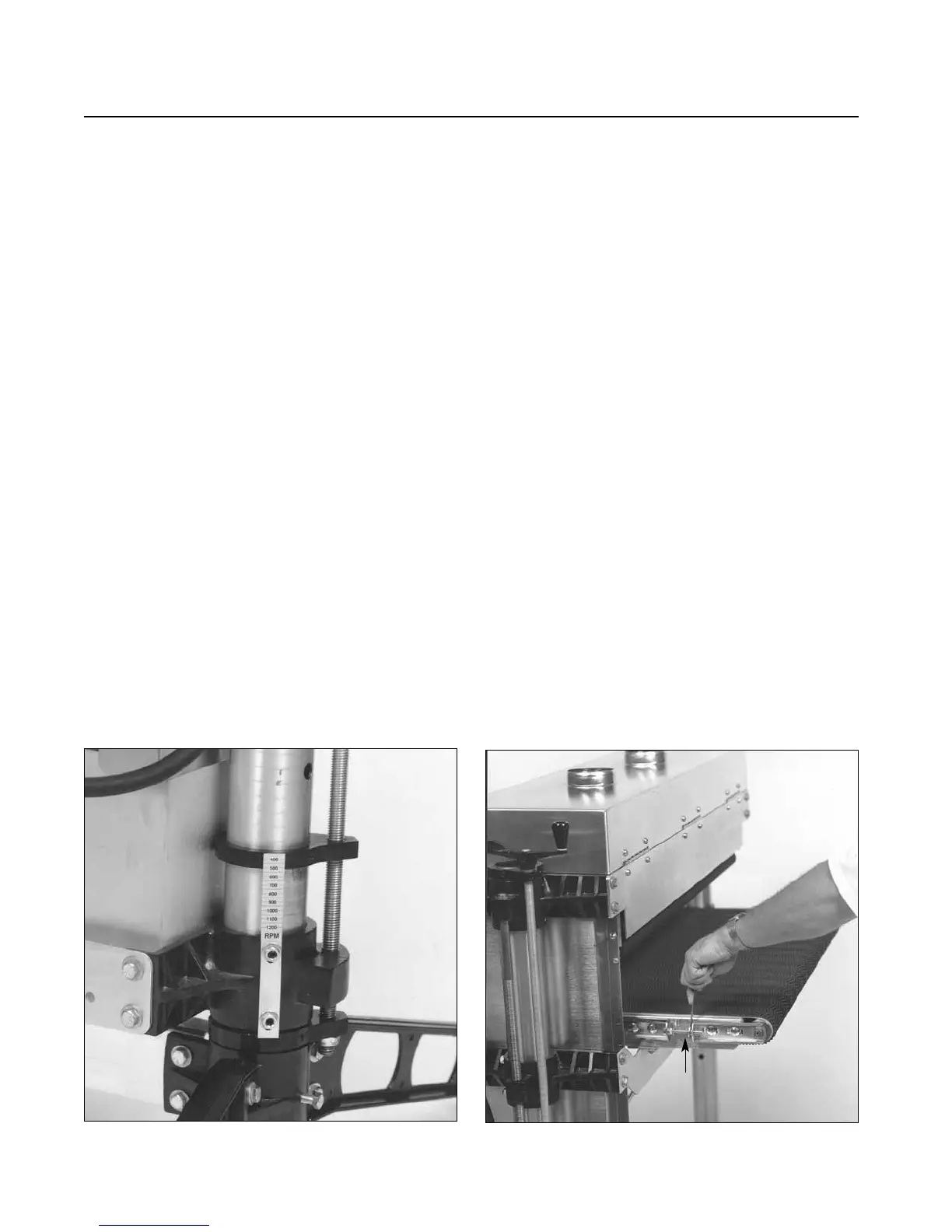

BRUSH SPEED ADJUSTMENT

The SUPERBRUSH is equipped with a variable

speed drive which allows the brush to be operated

anywhere between 400 and 1200 RPM. The faster

the brush speed, the more aggressive the brush

action. The brush speed control handle (1)(Fig. 5)

raises or lowers the motor support casting (7)(Fig.

5) which activates the variable speed drive pulley.

RPM GAUGE

The RPM gauge (Fig. 8) displays the brush speed

and is read where the scale intersects the top of the

screw support casting. To calibrate the gauge,

lower the motor to the lowest position. Loosen

both hex nuts while holding set screws. Position

the RPM scale so that “400” RPM intersects the

top of the screw support casting (Fig. 8). Tighten

hex nuts to hold gauge in this position.

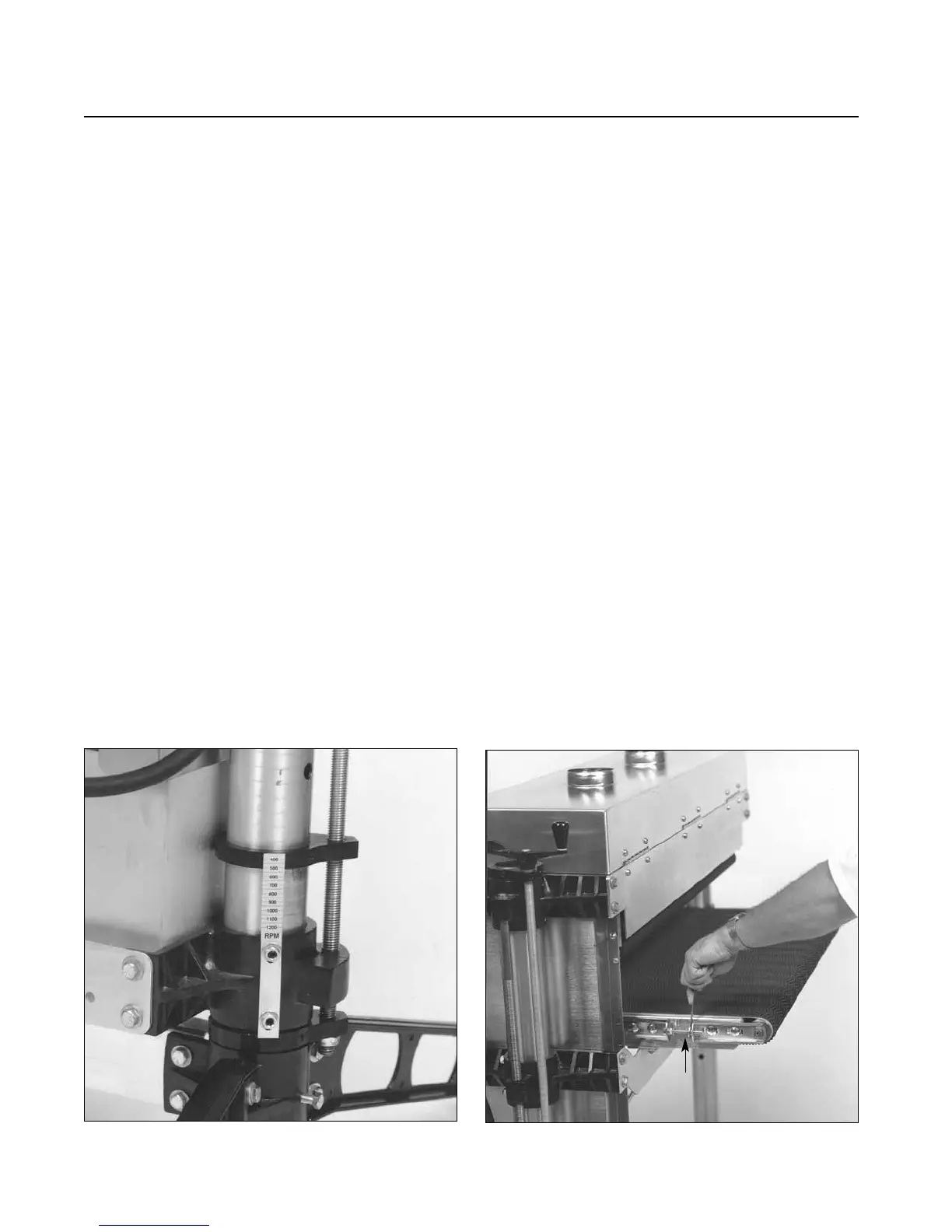

CHECKING THE CONVEYOR BELT

Conveyor belt tracking adjustments may occasionally

be necessary during break-in and normal operation to

compensate for belt stretching. If adjustments are

necessary, follow the instructions below:

Belt tracking adjustments are made while the

conveyor belt is running. With the conveyor unit

on and set at the fastest speed setting, watch for a

tendency of the conveyor belt to drift to one side

of the conveyor. To adjust the belt tracking, tighten

the take-up screw nut (see Fig. 9) on the side the

belt is drifting toward, and loosen the take-up

screw nut on the opposite side. Adjusting the take-up

screw nuts on either side of the conveyor allows

belt tracking adjustments to be made without

affecting belt tension. Adjust the take-up screw nuts

only 1/4 turn at a time. Then allow time for the belt

to react to the adjustments before proceeding further.

Try to avoid over-adjustments.

NOTE: Make sure wrench is below surface when

brushing.

Fig. 8. Brush RPM gauge.

Fig. 9. Adjusting conveyor belt tracking.

TAKE UP

SCREW NUT

Loading...

Loading...