24 SUPERBRUSH OWNER’S MANUAL

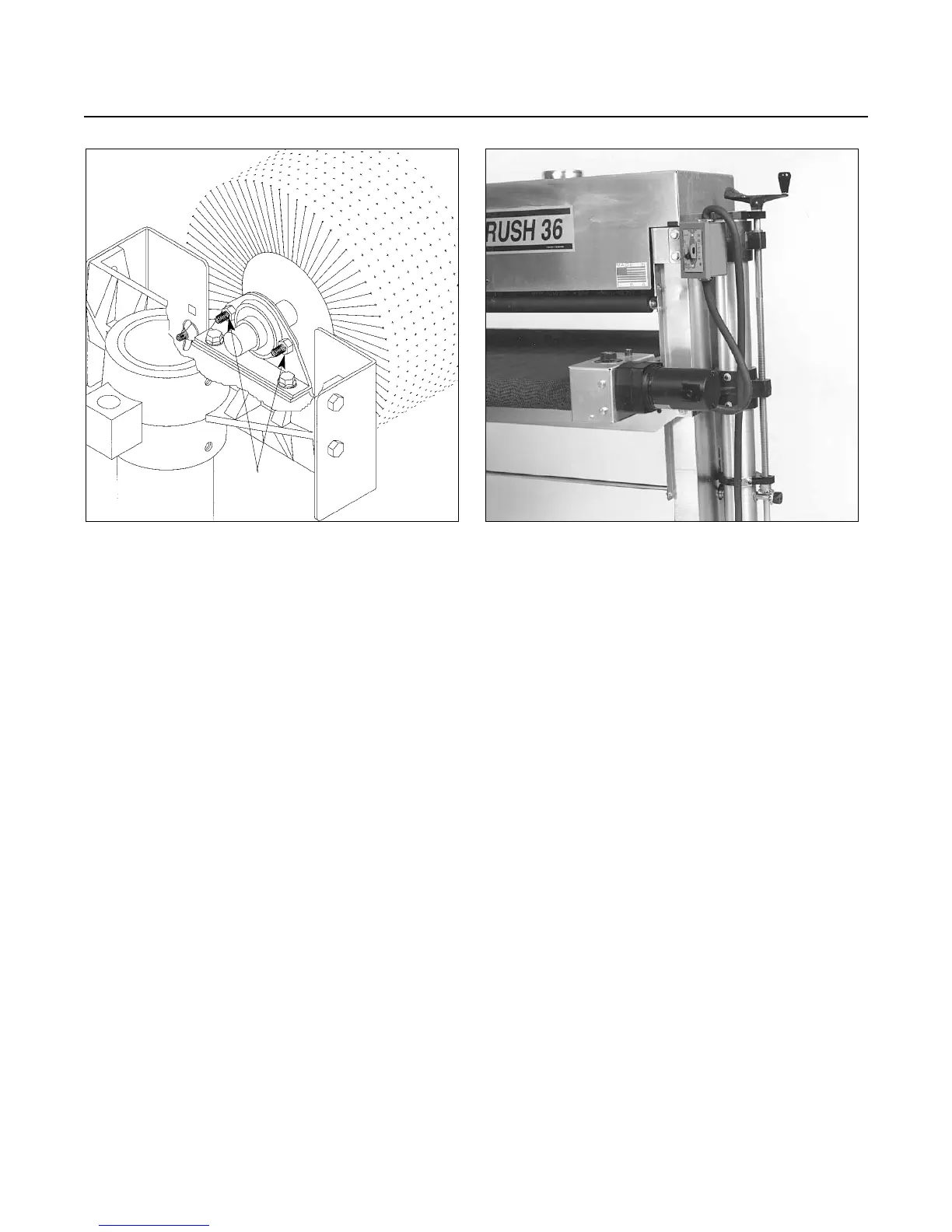

and the bearing flange for one bearing at a time.

Spin the brush within the collar, then tighten the

bolts in the bearing flange and then the set screws.

9. Test-run the S

UPERBRUSH before brushing stock

to check that all is operating properly and is

aligned before brushing good stock. Also, stop the

S

UPERBRUSH after a couple hours of use and check

the bolts and set screws to make sure they are seated

properly.

RR

EEPPLLAACCIINNGG

EE

LLEECCTTRRIICCAALL

CC

OOMMPPOONNEENNTTSS

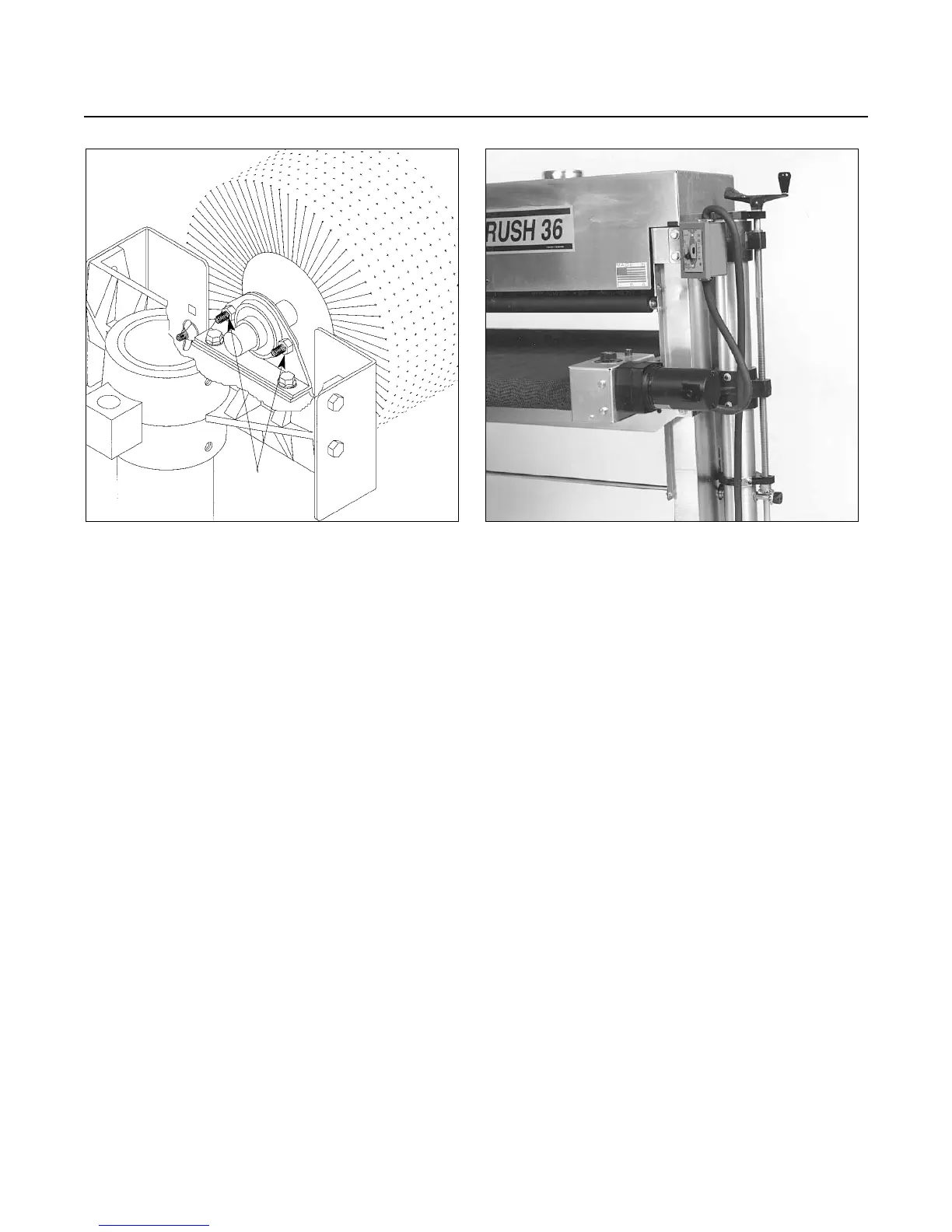

To replace either the variable-speed controller, or

the conveyor motor, use the following disassembly

procedure (Fig. 26 and pages 25 and 26):

Disconnect the power supply to the machine.

Next, remove the bottom plate from the control

box. Loosen the set screw in the shaft coupler, and

then remove the four 5/16˝ bolts that hold the

power feed motor assembly in place. Next, remove

the assembly from the machine and turn it upside

down to disconnect the leads from the components

to be removed.

To replace the controller, remove the variable

speed control knob. Remove the nut that holds

the controller in place and pull the controller out

of the housing. Install the new controller, referring

to the correct electrical diagram and reverse the

disassembly procedure.

To replace on/off switch, make sure power is

disconnected to sander. Remove the two screws

holding the front cover of the switch in place.

Disconnect and mark wire leads connected to

switch mechanism. Remove switch from box and

install new switch. Connect wires to new switch

following the wiring diagram and marked wires.

IMPORTANT: Make sure bare wire does not

touch any other wire or the switch box when

connected. Install switch assembly and cover.

To replace the conveyor gear motor, disconnect

the two wire leads from the controller. Also

disconnect the plastic grommet protecting the

wires passing through the housing. Remove the

four cap head set screws that hold the motor to the

housing bracket. Remove the old motor and

install new motor. Install the wiring leads according

to the electrical diagram pertaining to the correct

model (See following diagrams).

To replace conveyor fuse (Fig. 4), push and

turn fuse cap 1/8 turn counter clockwise. Pull cap

with fuse from base. Pull fuse from cap and

replace with 3/4 amp fuse (pages 25 and 26).

Place fuse and cap into base, push and turn 1/8

turn clockwise to secure.

Fig. 25. Supporting brushes to remove bearings. Fig. 26. Conveyor motor control box and brush

on/off switch.

BEARING

BOLTS

Loading...

Loading...