SERVICING YOUR SUPERBRUSH 23

Replacing Right (Inboard) Bearing:

Disconnect power source to brush.

1. Lower motor to its lowest position using the

RPM adjustment handle. Then raise motor to its

highest position using the RPM adjustment handle.

This loosens the V-belt tension so the V-belt can

be lifted off the driven pulley.

2. Raise conveyor table so brush rests on conveyor.

3. Remove left (outboard) bearing by removing the

two carriage bolts from bearing.

4. Remove the right (inboard) bearing by removing

the two carriage bolts from bearing.

5. Remove V-belt from driven pulley.

6. Lift brush head out from machine.

7. Loosen set screws in bearing collar and driven

pulley and remove from brush shaft.

8. Install new bearing and driven pulley. Do not

tighten set screws at this time.

9. Install brush in machine and center before

tightening bolts. Tighten bearing bolts and then

set screws in bearings.

10. Install V-belt on driven pulley and adjust pulley

for proper V-belt alignment before tightening

pulley set screw.

11. Check the alignment of the brush to the

conveyor system.

REPLACING BRUSH HEAD

1. Lower motor to its lowest position using the

RPM adjustment handle. Then raise motor to its

highest position using the RPM adjustment handle.

This loosens the V-belt tension so the V-belt can

be lifted off the driven pulley.

2. Remove the bearing bolts (Fig. 19, 19A and 25)

and lift brush out of machine. Note: Some models

have two mounting bolts attaching the bearing

housing down into the brush support bracket.

These two bolts can be used to remove the brush

head instead of the bolts through the bearing

flange.

3. Loosen set screws in bearing collars and driven

pulley and remove from brush shaft.

4. Install new bearings and driven pulley. Do not

tighten set screws at this time.

5. Install brush in machine and center before

tightening bearing bolts. Tighten bearing bolts

and then set screws in bearings.

6. Install V-belt on driven pulley and adjust pulley

for proper V-belt alignment before tightening

pulley set screw.

7. Check the alignment of the brush to the conveyor

system. (For instructions on this procedure, see

page 7 of this manual).

8. Lower the conveyor and spin the brush by hand

to make sure the brush shaft is not binding in the

bearing. If the bearings bind, loosen the set screws

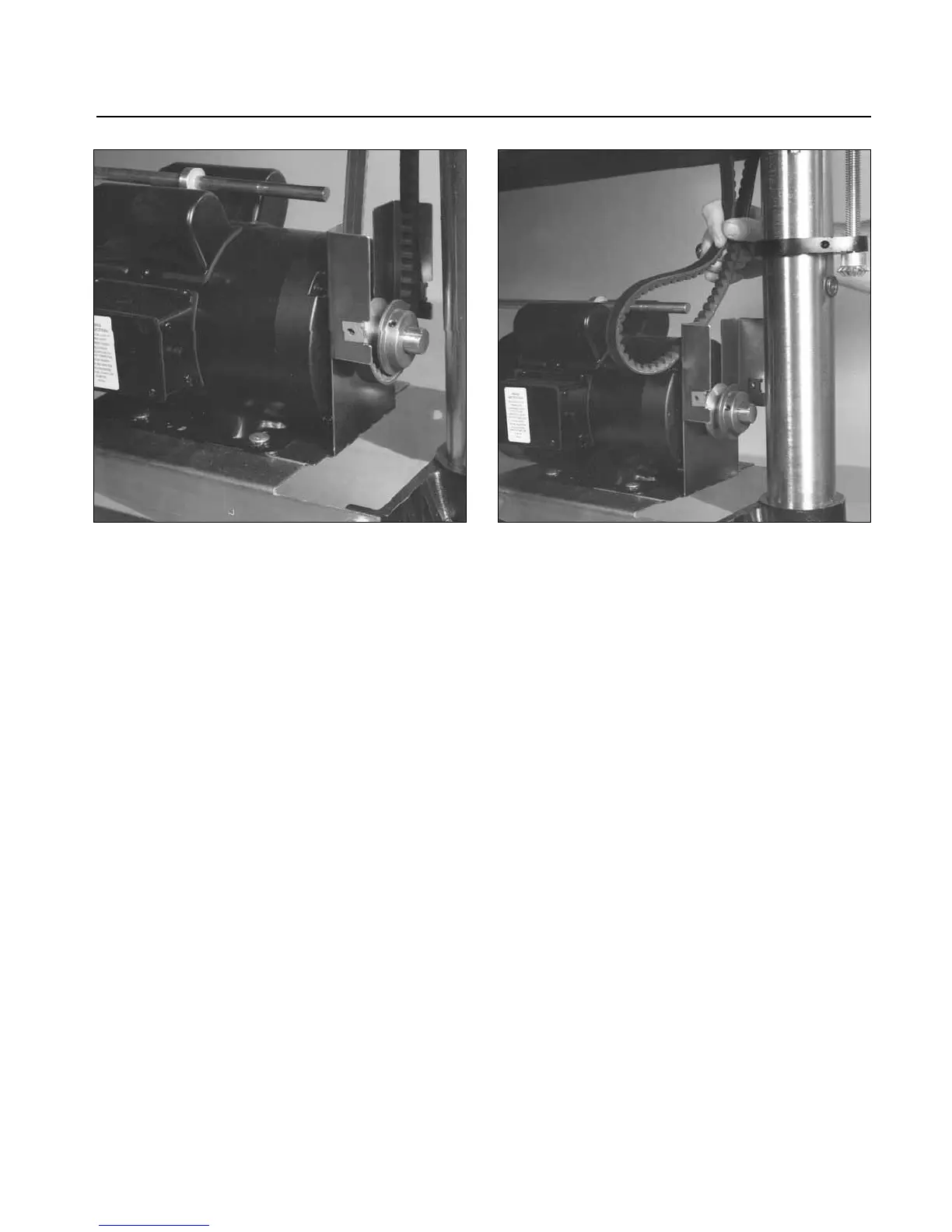

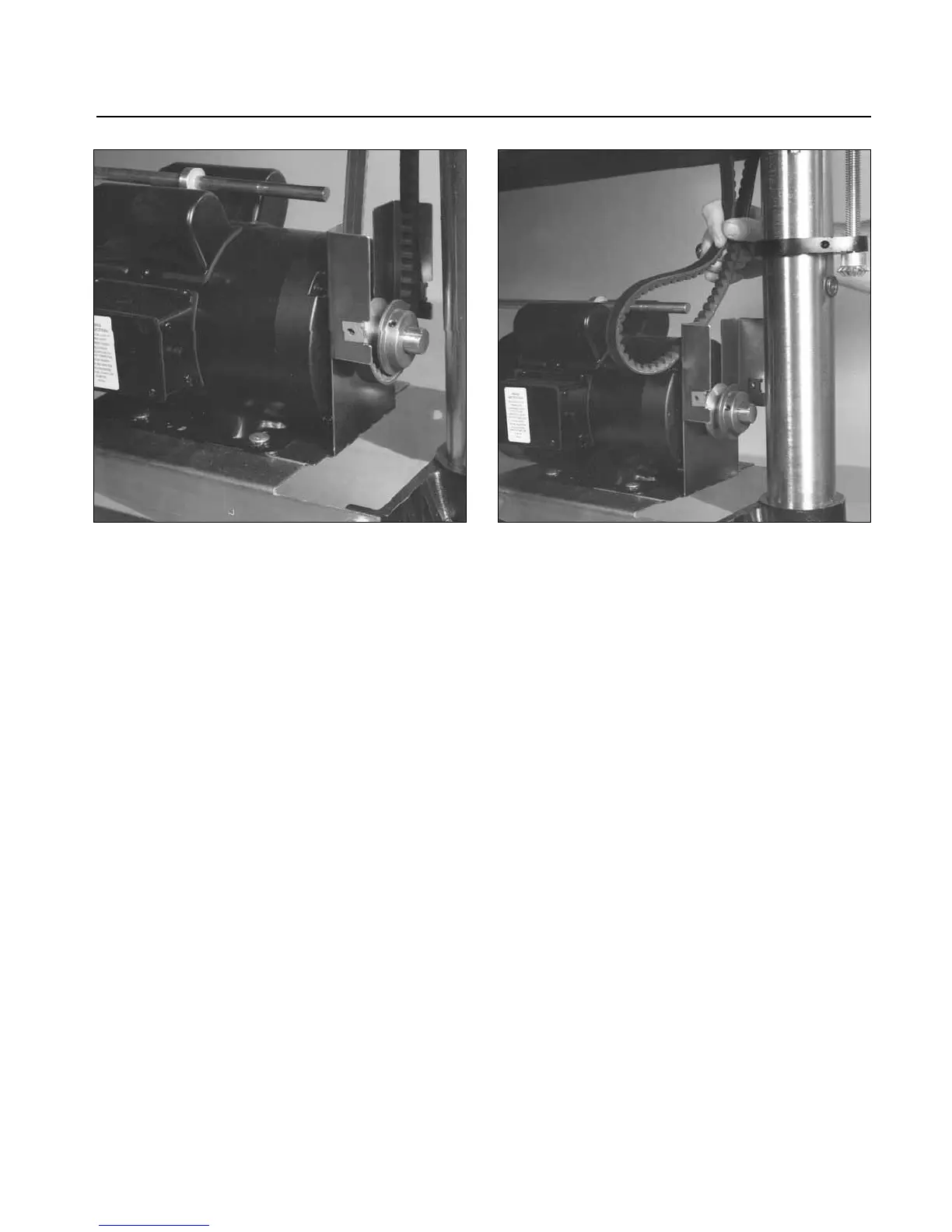

Fig. 23. Removing lower guard and transfer rod. Fig. 24. Removing main motor V-belt drive.

Loading...

Loading...