22 SUPERBRUSH OWNER’S MANUAL

ROTATING/REPLACING BRUSH BEARINGS

Replacing the permanently lubricated bearings on

the S

UPERBRUSH is a relatively straight-forward

procedure. Bearings should be replaced when they

allow excessive play of the brush, make excessive

noise, or otherwise indicate failure.

Note that if clicking noises in the bearings are a

problem, rotating may be a solution instead of

replacement, as follows:

BEARING ROTATING

Step 1. Loosen the set screws in the bearing collar.

Leave the set screw wrench in one of the set

screws. Then rotate the brush within the bearing

and tighten the set screws (Fig. 19 and 20).

Step 2. If the clicking persists, or if the brush shaft

is tight in the bearing and cannot rotate, then

loosen the two bolts holding the bearing and the

flange for the bearing. Now repeat Step 1. After

the brush is rotated within the bearing, tighten the

flanges first and then the set screws. After the

machine has run for a half hour, stop to check that

the set screws and bearing bolts are tight.

Bearing Replacement:

1. Disconnect power source to the machine.

2. Lower motor to its lowest position using the

RPM adjustment handle. Then raise motor to its

highest position using the RPM adjustment han-

dle. This loosens the V-belt tension so the V-belt

can be lifted off the driven pulley.

3. Raise conveyor bed until the brush rests on

bed.

If replacing both bearings, begin with bearing on

the left (outboard) side.

Replacing Left (Outboard) Bearing:

Make sure power is disconnected to the machine.

1.Remove the outer half of the bearing flange.

Loosen the set screws in the bearing collars and

remove the bearing.

2. If the shaft of the brush is rough from the set

screws, use emery cloth or sandpaper to smooth

down any raised edges. Slide the new bearing on

the shaft, but do not tighten the set screws yet.

3. Install the outer half of the original bearing

flange and tighten the bolts. Then tighten the set

screw in the bearing collar.

If the left (outboard) bearing is the only one that

needs changing, proceed to reassemble the unit.

You can check the brush at this point by lowering

the conveyor bed and spinning the brush by hand.

This will help determine if the inboard bearing

needs to be changed to eliminate noise or excessive

play in the brush.

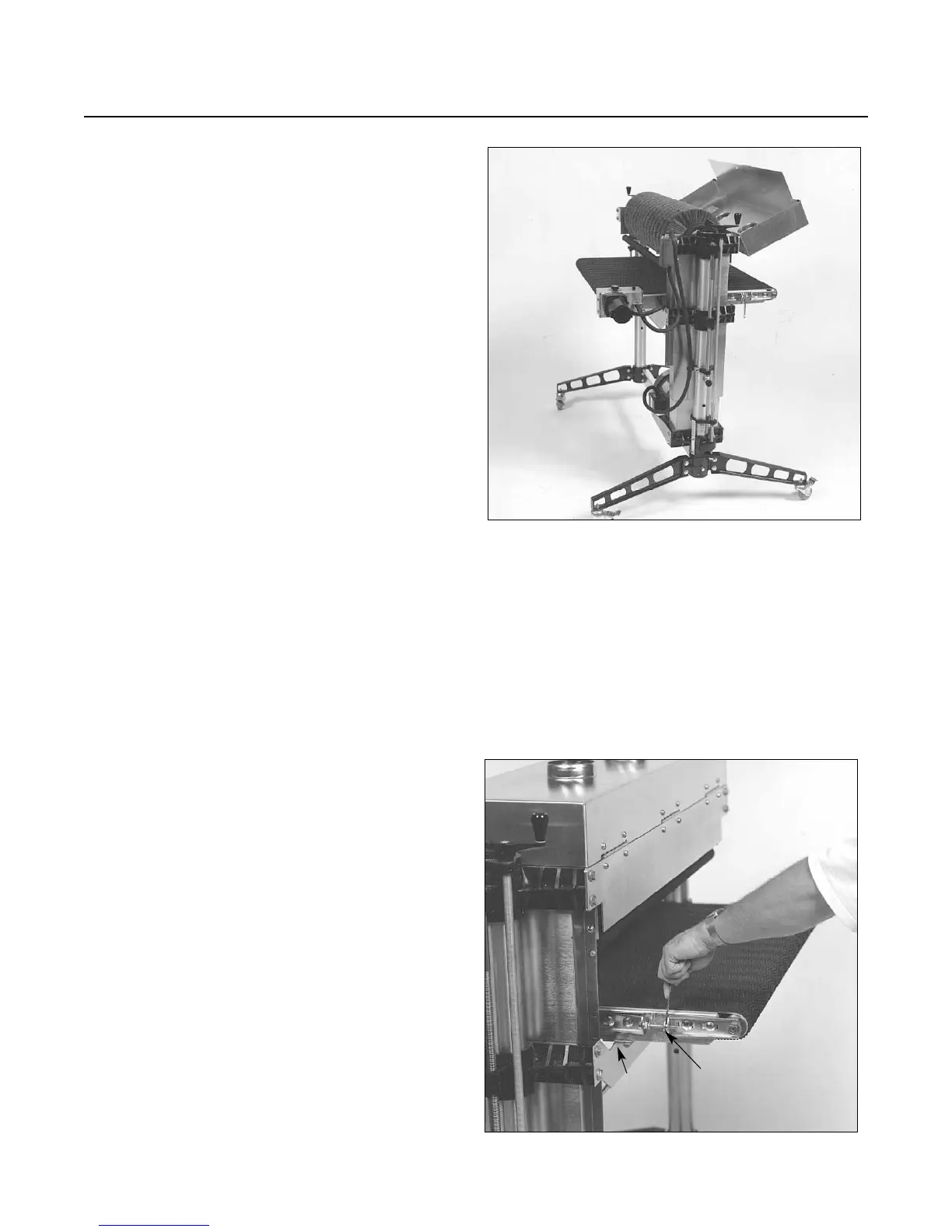

Fig. 20. Conveyor belt replacement.

Fig. 21. Tensioning and tracking conveyor belt.

CONVEYOR

MOUNTING

BOLTS

TAKE UP

SCREW NUT

Loading...

Loading...