1. General Information

1-11

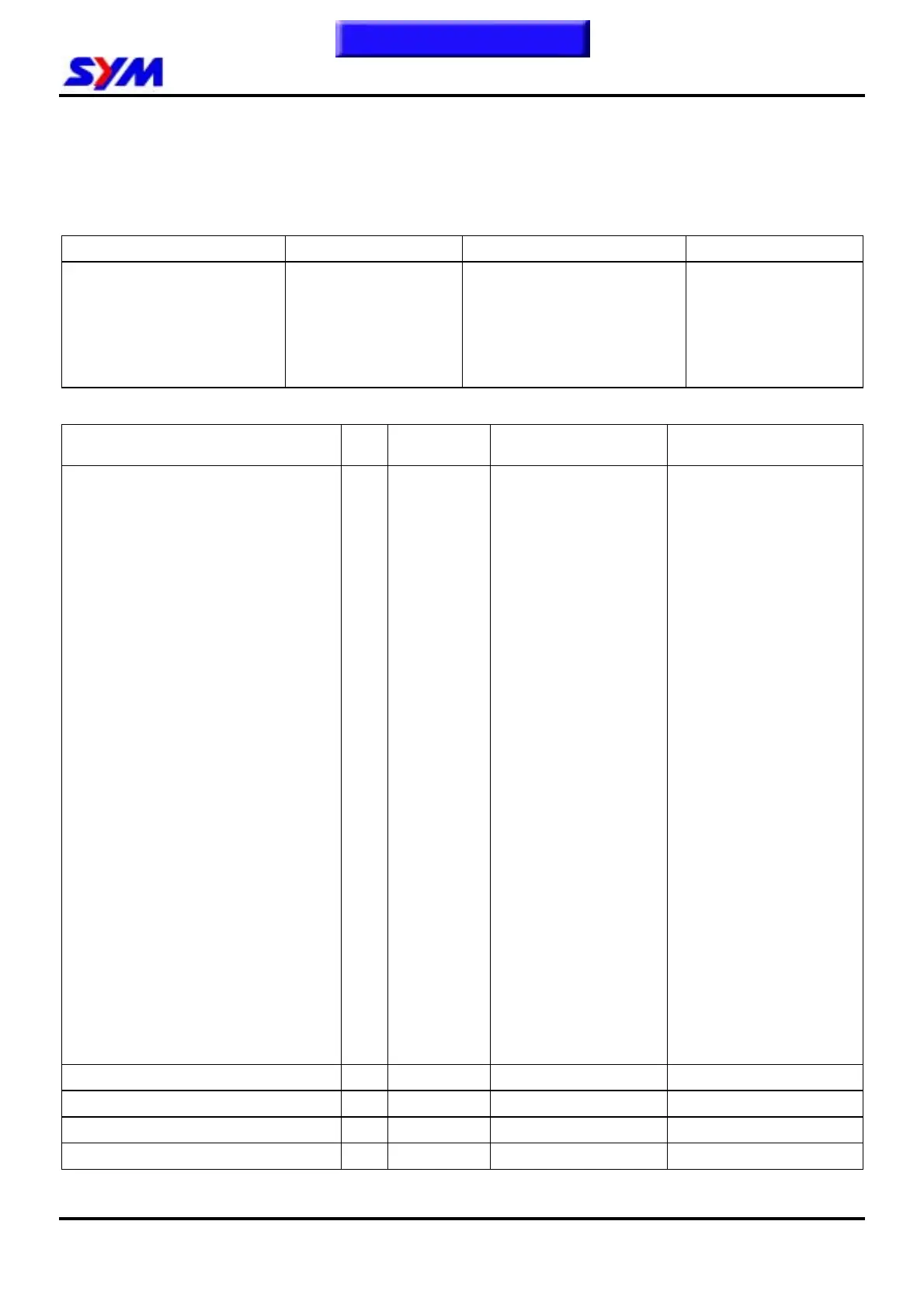

Torque Values

The torque values listed in above table are for more important tighten torque values. Please see standard

values for not listed in the table.

Standard Torque Values for Reference

Type Tighten Torque Type Tighten Torque

5 mm bolt、nut

0.45~0.6kgf-m 5 mm screw 0.35~0.5kgf-m

6 mm bolt、nut

0.8~1.2kgf-m

6 mm screw、SH nut

0.7~ 1.1kgf-m

8 mm bolt、nut

1.8~2.5kgf-m

6 mm bolt、nut

1.0 ~1.4kgf-m

10 mm bolt、nut

3.0~4.0kgf-m

8 mm bolt、nut

2.4 ~3.0kgf-m

12 mm bolt、nut

5.0~6.0kgf-m

10 mm bolt、nut

3.5~4.5kgf-m

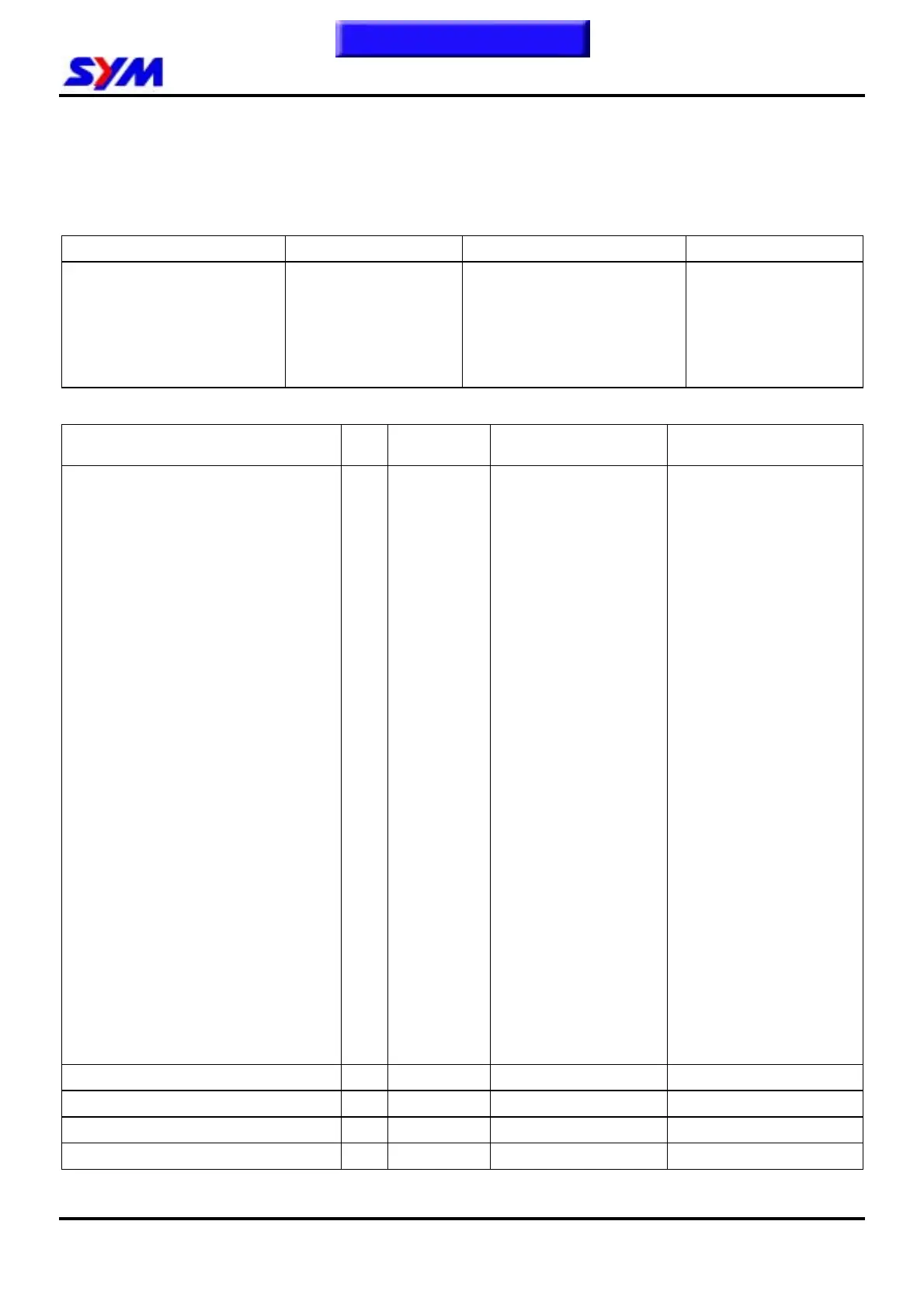

Engine Torque Values

Item Q’ty

Thread Dia.

(mm)

Torque Value(kgf-m) Remarks

Cylinder stud bolt 4 8 0.7~1.0 Tighten to crankcase

Cylinder head nut 4 8 1.8~2.2 Apply oil to thread

Cylinder head left bolt 2 6 1.0~1.4

Cylinder head side cover bolt 2 6 1.0~1.4

Valve adjustment cap 2 30 1.3~1.7

Tappet adjustment screw nut 4 5 0.7~1.1 Apply oil to thread

Spark plug 1 10 1.0~1.4

Cylinder head stud bolt (inlet pipe) 2 6 0.7~1.0

Cylinder head stud bolt (EX. pipe) 2 6 0.7~1.0

Tensioner lifter bolt 2 6 1.0~1.4

Tensioner bolt 1 6 0.8~1.2 Socket bolt

Carburetor insulator bolt 2 6 0.7~1.0

Oil pump screw 2 3 0.1~0.3

Engine left cover bolt 7 6 1.0~1.5

Engine oil draining bolt 1 12 3.5~4.5

Engine oil strainer cap 1 30 1.3~1.7

Mission draining bolt 1 8 0.8~1.2

Mission filling bolt 1 10 1.0~1.4

Clutch driving plate nut 1 28 5.0~6.0

Clutch outer nut 1 12 5.0~6.0

Drive face nut 1 12 5.0~6.0

ACG. Flywheel nut 1 12 5.0~6.0

Crankcase bolts 7 6 1.5~2.0

Mission case bolt 7 8 2.0~2.4

One-way clutch tighten bolts 3 6 1.0~1.4 Apply locking sealant

One-way clutch tighten nut 1 22 9.0~10.0 Apply oil to thread

Exhaust pipe bolts 2 8 3.0~3.6

Exhaust pipe connection nuts 2 6 1.0~1.4

To this chapter contents

Loading...

Loading...