7. Cylinder Head / Valve

7-8

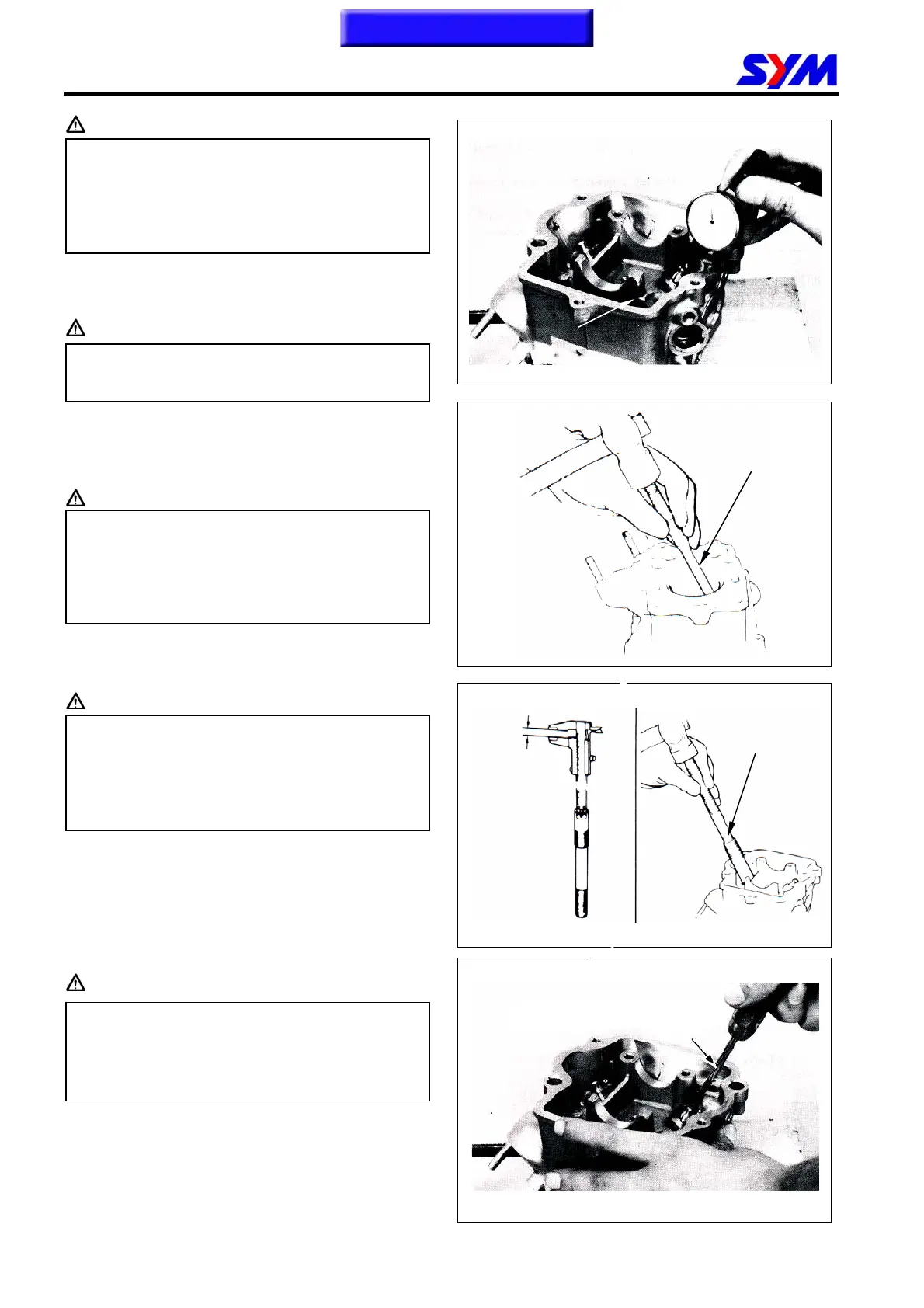

Caution

Correct it with reamer after replacement.

If clearance still exceeds service limit after

replaced valve guide, replace valve stem too.

Caution

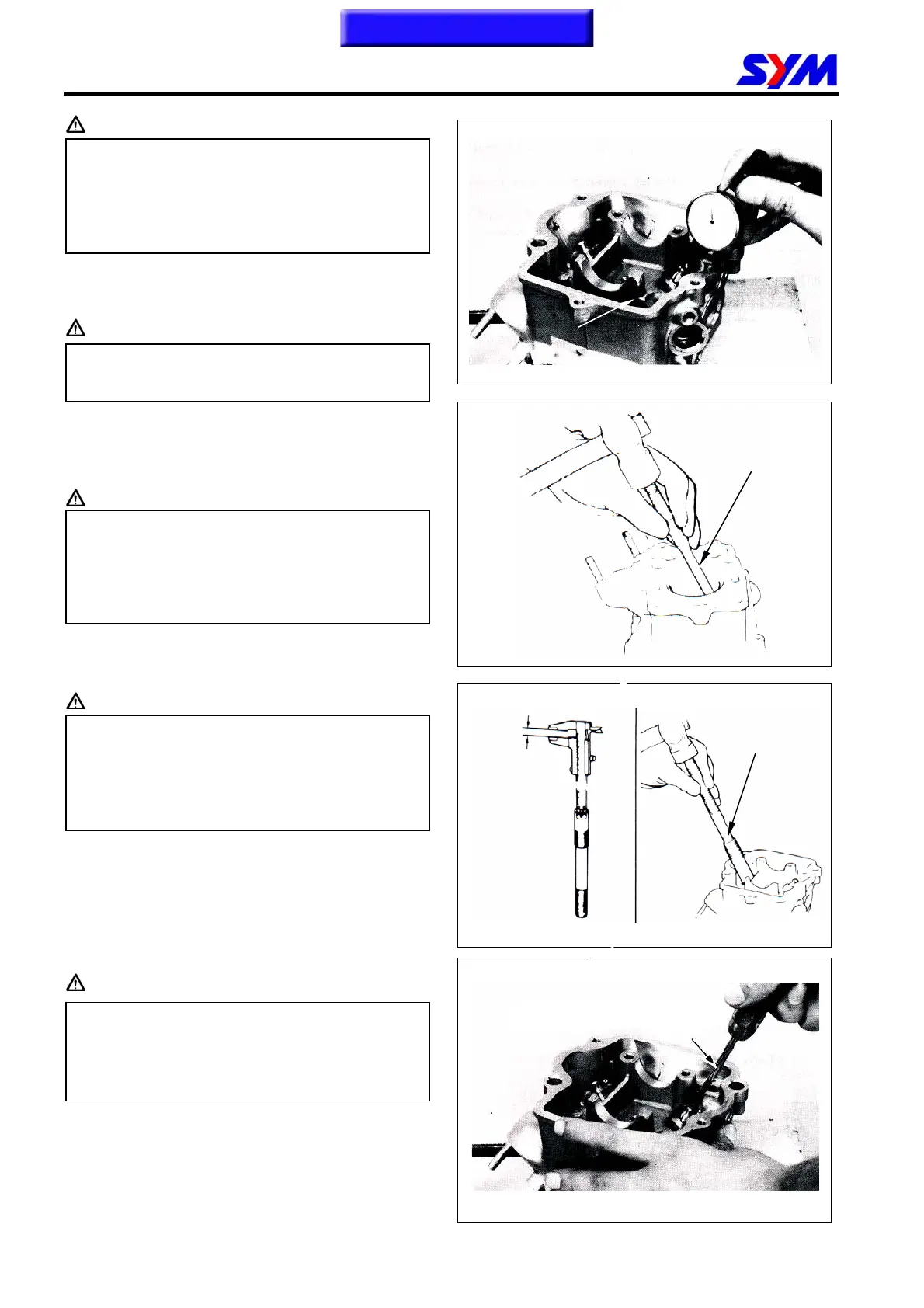

Valve Stem Replacement

Heat up cylinder head to 100~150 ℃ with

heated plate or toaster.

Caution

Hold the cylinder head, and then press out old

valve guide from combustion chamber side.

Tool: Valve guide driver: 5.0 mm

Caution

Adjust the valve guide driver and let valve guide

height is in 13 mm.

Press in new valve guide from rocker arm side.

Tool: Valve guide driver: 5.0 mm

Wait for the cylinder head cooling down to room

temperature, and then correct the new valve

guide with reamer.

Caution

Correct valve seat, and clean up all metal

residues from cylinder head.

Tool: Valve guide reamer: 5.0 mm

z If clearance between valve stem and

valve guide exceeded service limit, check

whether the new clearance that only

replaces new valve guide is within service

limit or not. If so, replace valve guide.

It has to correct valve seat when replacing

valve guide.

z Do not let torch heat cylinder head

directly. Otherwise, the cylinder head may

be deformed as heating it.

z Wear on a pair of glove to protect your

hands when operating.

z Check if new valve guide is deformation

after pressed it in.

z When pressing in the new valve guide,

cylinder head still have to be kept in

100~150℃.

Valve guide driver

5.0mm

Valve guide driver

5.0 mm

13 mm

Valve guide reamer 5.0 mm

z Using cutting oil when correcting valve

guide with a reamer.

z Turn the reamer in same direction when it

be inserted or rotated.

To this chapter contents

Loading...

Loading...