Appendix B

B–24 TA I

NSTRUMENTS

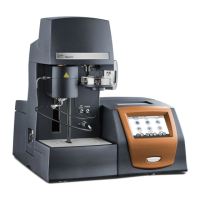

TGA 2950

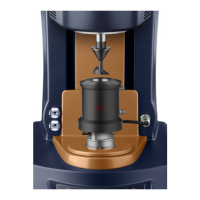

When used with semi-pressurized sample

containment, constant reaction rate mode

becomes even more powerful. The vapor

pressure which builds up inside the sample

container limits the rate of reaction of the

sample. This allows the reaction to complete at

a nearly constant rate and temperature. The

reaction progresses more uniformly throughout

the sample because vapor pressure gradients in

and around the sample material are substantially

reduced. The onset of higher temperature

reactions is effectively suppressed until the

completion of lower temperature reactions.

Constant reaction rate mode is preferred for any

sample where it is important to limit or control

the rate of reaction. These may include pyro-

technics, self-heating reactions, auto-catalyzing

reactions and gas diffusion reactions. Constant

reaction rate mode is also a good choice when it

is important to accurately determine the transi-

tion temperature at a given reaction rate.

Another area where constant reaction rate

heating can be helpful, is when the sample

material exhibits a relatively large and some-

what constant background weight change, onto

which is superimposed a relatively small transi-

tion. If the decomposition rate threshold is

chosen to be close to the background percent/

minute at the maximum heating rate, then the

heating rate will only be changed significantly

when the smaller transition occurs.

Derivative of weight change curves that are

plotted versus temperature may appear cyclic

and have negative peaks as well as positive

ones. This effect is caused by the automatic

application of cooling whenever the rate of

Loading...

Loading...