MAINTENANCE

Every 500 Hours

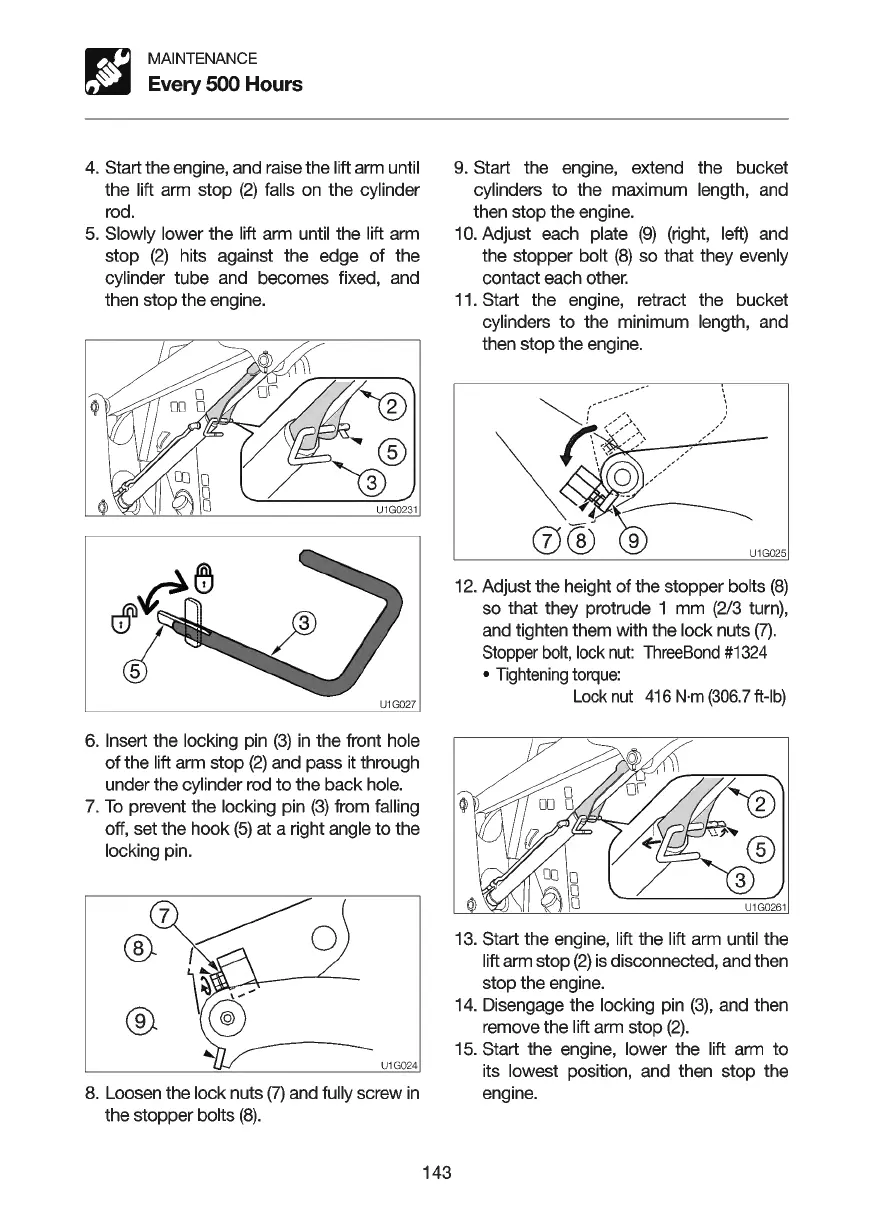

4. Start the engine, and raise the lift arm until

the lift arm stop

(2)

falls on the cylinder

rod.

5.

Slowly lower the lift arm until the lift arm

stop

(2)

hits against the edge

of

the

cylinder tube and becomes fixed, and

then stop the engine.

6. Insert the locking pin

(3)

in

the front hole

of the lift arm stop

(2)

and pass

it

through

under the cylinder rod to the back hole.

7.

To

prevent the locking

pin

(3)

from falling

off, set the hook

(5)

at a right angle to the

locking pin.

®

U1G024

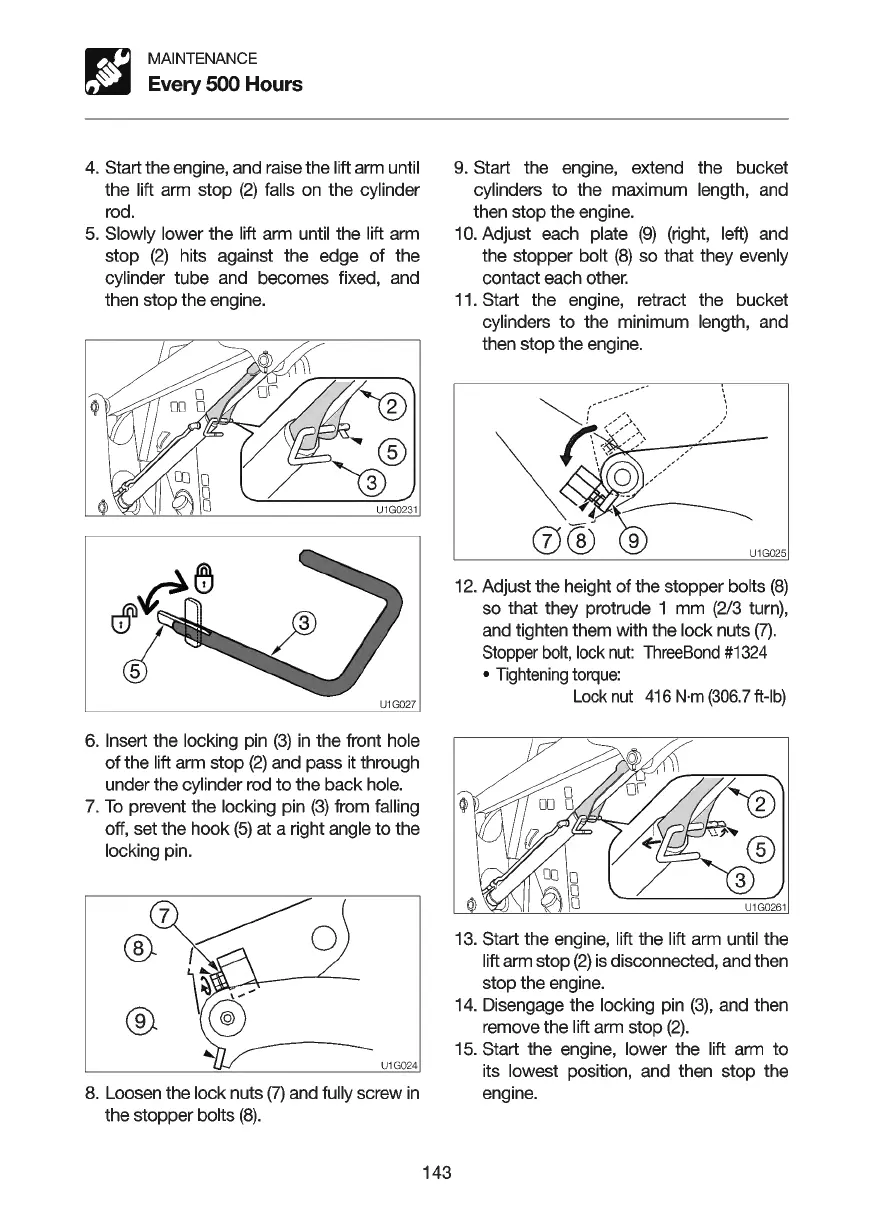

8. Loosen the lock nuts

(7)

and fully screw

in

the stopper bolts

(8).

143

9. Start the engine, extend the bucket

cylinders to the maximum length, and

then stop the engine.

10.

Adjust each plate

(9)

(right, left) and

the stopper bolt

(8)

so that they evenly

contact each

other.

11

. Start the engine, retract the bucket

cylinders to the minimum length, and

then stop the engine.

12.

Adjust the height

of

the stopper bolts

(8)

so that they protrude 1 mm (2/3 turn),

and tighten them with the lock nuts

(7).

Stopper

bolt,

lock

nut:

ThreeBond

#1324

•

Tightening

torque

:

Lock

nut

416

N·m

(306.7

ft-lb)

13.

Start the engine, lift the lift arm until the

lift arm stop

(2)

is

disconnected, and then

stop the engine.

14.

Disengage the locking pin

(3),

and then

remove the lift arm stop

(2).

15.

Start the engine, lower the lift arm to

its lowest position, and then stop the

engine.

Loading...

Loading...