22

LOCK MENU - OPEN

TROUBLESHOOT

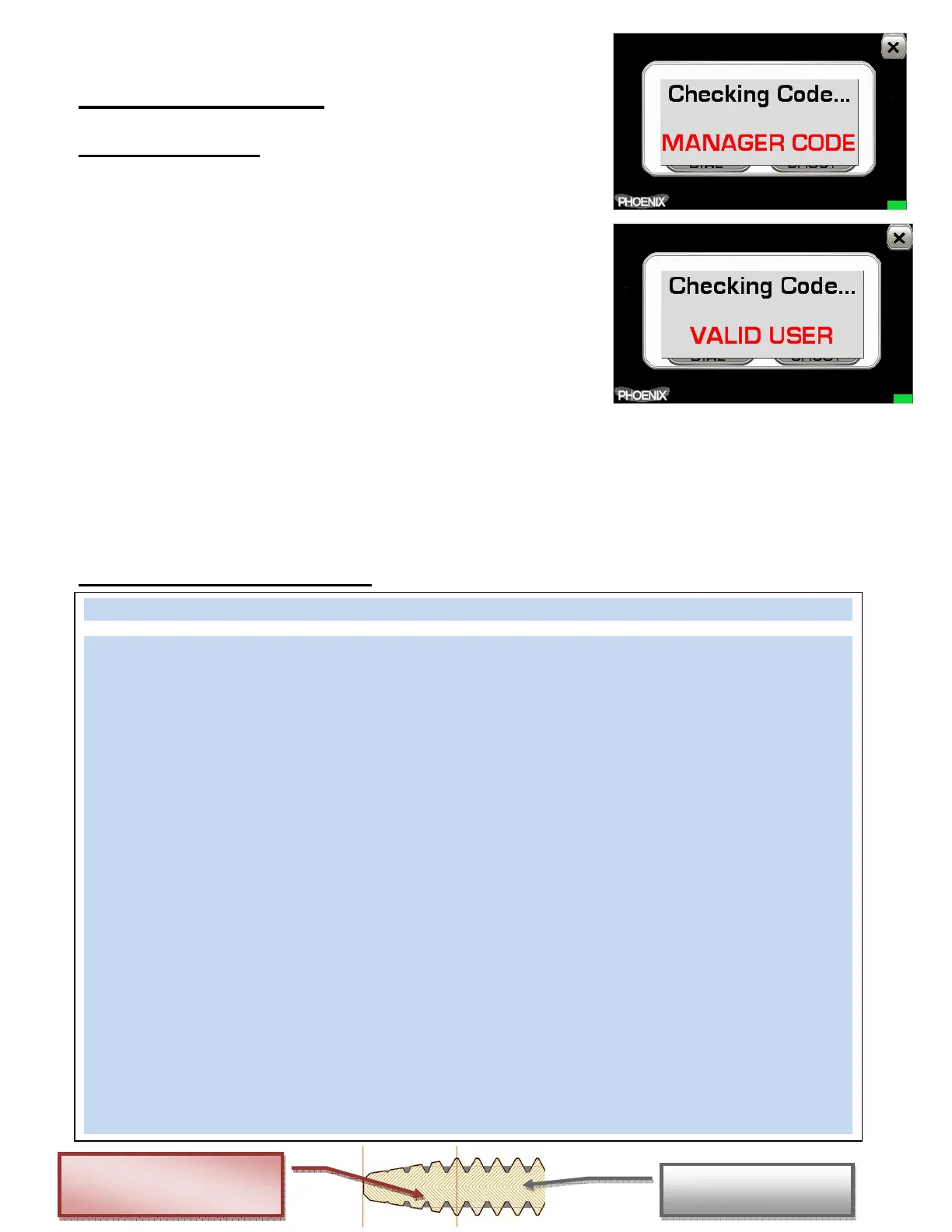

This is the best option when you have a suspected code

but the lock is not opening as expected. This could be the

result of a defective electronic component (ie. keypad

cable), faulty mechanical component (ie. drive nut,

solenoid), the current lock state (ie. penalty lockout, time

delay) or a simple invalid code.

The first step in the troubleshooting process will look for

issues such as communication problems and penalty

lockout conditions. If these can be remedied then the

Phoenix will begin to confirm the supplied code. If the code is determined valid then the

Phoenix assumes that the problem must be mechanical in nature and will use its built-in

JumpBox circuit along with its pre-programmed diagnostic routines to repair and open

the lock. Examples of these issues include stuck solenoids, stalled bolts and cross-

threaded drive nuts. In many of these cases the lock can be re-used after repair.

In-Depth - Lock Repair Process

“I understand the Phoenix might get it open but the tool can’t actually repair a lock, right?”

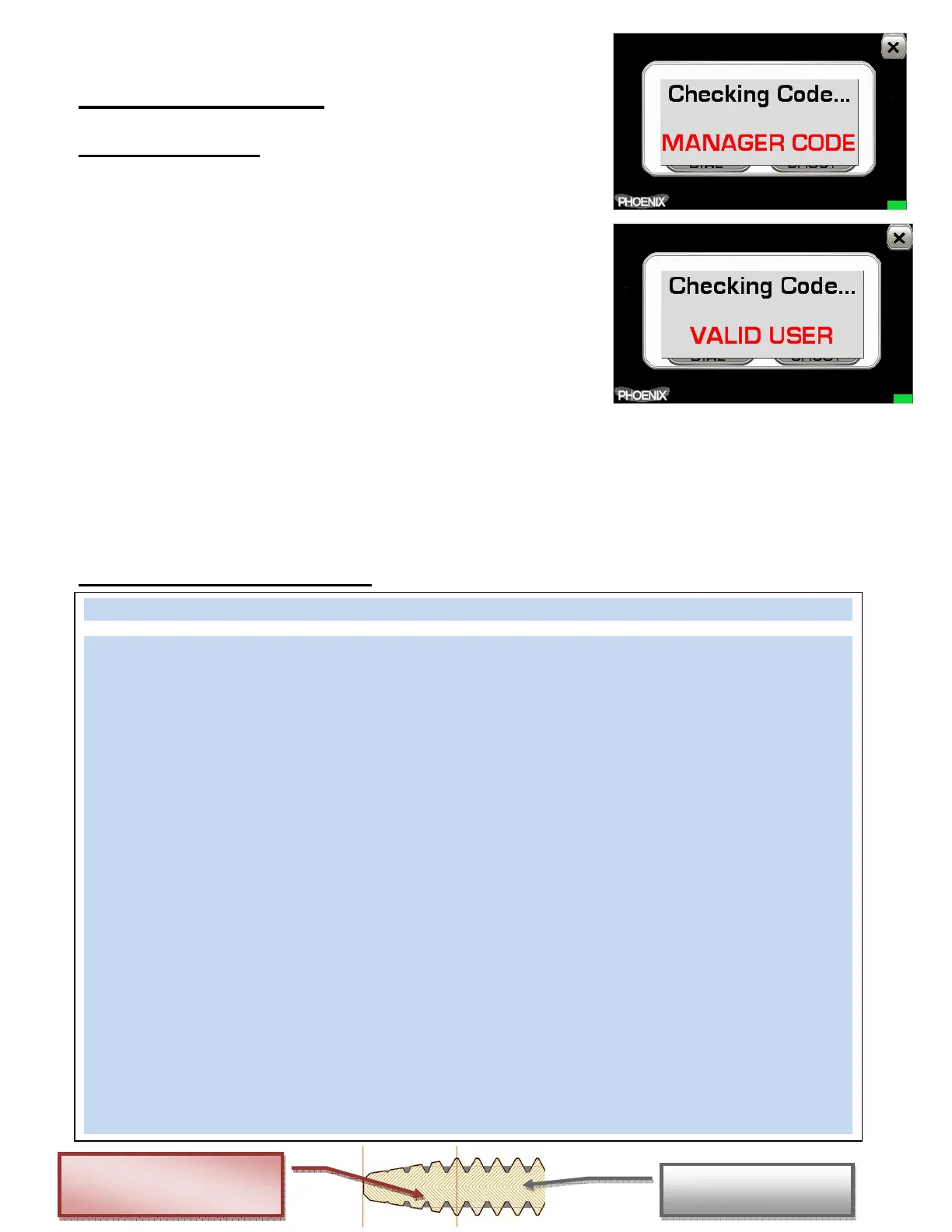

In some cases the Phoenix can indeed repair a mechanically defective lock. The best

illustration of this physical repair process is a S&G 6120 series lock with a cross-threaded

drive nut. These locks exhibit a tell-tale faint click followed by a 2

nd

faint click when running

the code. This is caused by the design of the drive mechanism which uses a plastic drive

nut traveling on a threaded brass shaft to retract the lock bolt. For proper bolt extension

this design requires the threads on the end of the brass drive shaft to be tapered similar to

a hand tap. Normally this system works fine but with increased use a potential problem

arises. When closely examining the defective 6120 locks used in our e-lock drilling classes,

we noticed that the locks removed for cross-threaded drive nuts had a fine gray powder

built-up between the brass threads on the drive shaft. This powder was deposited over time

as the black plastic drive nut slowly wore. On the tapered threads this powder was enough

to fill the small valleys between threads and resulted in the drive nut jumping a thread on

one side of the driveshaft resulting in a cross-thread. By threading the nut off by hand and

wiping or spraying away the fine powder the locks functioned perfectly. Countless

“defective” 6120’s have now been put back into service using this repair method either by

hand or with the Phoenix tool. The Phoenix tackles a cross-thread by first using it’s

JumpBox circuit to spin the motor OUT rather than in (just as you’d do by hand). If needed,

it also pulses the motor to create an impact-like effect which dislodges the seized nut. Once

the nut is free, the tool uses it’s JumpBox to rotate the motor in high speed pulses to

dislodge any built-up powder between the threads. It then does a sequence of “soft

openings”, lightly retracting the bolt and gauging the resistance. This process is repeated

until the Phoenix feels that the drive nut is operating smoothly and without resistance.

S&G 6120 Driveshaft

Loading...

Loading...