Adjustments—455/A2/B2

c. Center display with horizontal POSITION.

d. Set X10 MAG pushbutton in (on).

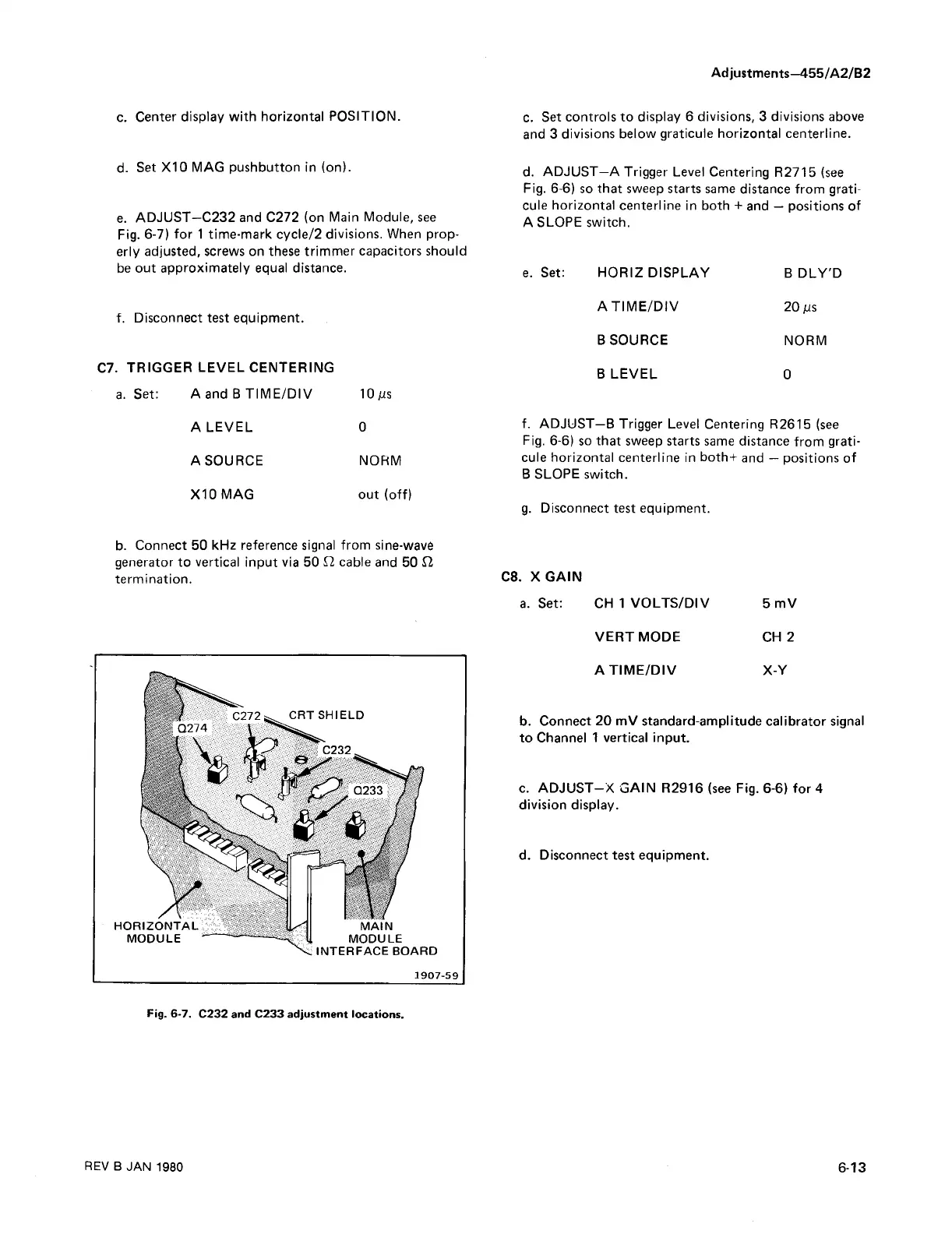

e. ADJUST—C232 and C272 (on Main Module, see

Fig. 6-7) for 1 time-mark cycle/2 divisions. When prop

erly adjusted, screws on these trimmer capacitors should

be out approximately equal distance.

f. Disconnect test equipment.

C7. TRIGGER LEVEL CENTERING

a. Set: A and B TIME/DIV 10jus

A LEVEL 0

A SOURCE NORM

X10MAG out (off)

c. Set controls to display 6 divisions, 3 divisions above

and 3 divisions below graticule horizontal centerline.

d. ADJUST—A Trigger Level Centering R2715 (see

Fig. 6-6) so that sweep starts same distance from grati

cule horizontal centerline in both + and — positions of

A SLOPE switch.

e. Set: HORIZ DISPLAY B DLY'D

ATIM E/DIV 20 ^s

BSOURCE NORM

B LEVEL 0

f. ADJUST—B Trigger Level Centering R2615 (see

Fig. 6-6) so that sweep starts same distance from grati

cule horizontal centerline in both+ and — positions of

B SLOPE switch.

g. Disconnect test equipment.

b. Connect 50 kHz reference signal from sine-wave

generator to vertical input via 50 £2 cable and 50 £2

termination.

C8. X GAIN

a. Set: CH 1 VOLTS/DIV 5 mV

VERT MODE CH 2

AT IM E/D IV X-Y

b. Connect 20 mV standard-amplitude calibrator signal

to Channel 1 vertical input.

c. ADJUST-X GAIN R2916 (see Fig. 6-6) for 4

division display.

d. Disconnect test equipment.

Fig. 6-7. C232 and C233 adjustment locations.

REV B JAN 1980

6-13

Loading...

Loading...